This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3640109 O-Ring Seal is a critical component in commercial truck maintenance and operation, designed to maintain the integrity of seals within various truck systems. This ensures the overall efficiency and reliability of the vehicle. Understanding the role and significance of this O-Ring Seal is essential for maintaining the performance and longevity of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3640109 O-Ring Seal in Truck Operation

The 3640109 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the seal integrity in systems where fluid or gas containment is required. It is commonly associated with fuel systems, hydraulic systems, and other critical components where leaks can lead to performance issues or safety concerns. By maintaining a reliable seal, this O-Ring contributes to the efficient operation of the truck 2.

Key Features of the 3640109 O-Ring Seal

The design and material characteristics of the 3640109 O-Ring Seal make it suitable for its intended application in trucks. It is crafted from materials that offer durability, resistance to various chemicals, and the ability to withstand high temperatures and pressures. These features ensure that the O-Ring can perform effectively under the demanding conditions encountered in commercial truck operations 3.

Benefits of Using the 3640109 O-Ring Seal

The advantages provided by the 3640109 O-Ring Seal include improved sealing performance, enhanced durability, and resistance to a range of operating conditions. Its design allows for a tight seal that minimizes the risk of leaks, contributing to the overall reliability and safety of the truck. Additionally, its material properties ensure longevity, reducing the need for frequent replacements 4.

Installation and Maintenance

Proper installation of the 3640109 O-Ring Seal involves several preparation steps and the use of appropriate tools. It is important to ensure that the groove in which the O-Ring will be placed is clean and free of debris to facilitate a proper seal. Maintenance tips to ensure the longevity and optimal performance of the O-Ring include regular inspection for signs of wear or damage and replacement as necessary to prevent leaks and maintain system integrity.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals in truck applications include leaks, which can be caused by wear, damage, or improper installation. Troubleshooting steps to address these issues effectively involve inspecting the O-Ring for signs of degradation, ensuring the groove is clean and properly sized, and replacing the O-Ring if necessary to restore the seal’s integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial truck operators and maintenance professionals.

Cummins O-Ring Seal 3640109 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3640109 is designed to fit seamlessly within various engine models, ensuring optimal sealing performance and reliability. This O-ring is integral to maintaining the integrity of the engine’s sealing systems, preventing leaks and ensuring efficient operation.

QSK38 CM2150 MCRS and QSK50 CM2150 MCRS

The O-Ring Seal 3640109 is compatible with the QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines. These engines benefit from the O-ring’s precise fit, which is crucial for maintaining the sealing integrity in high-pressure environments. The O-ring ensures that the engine’s components remain tightly sealed, preventing any fluid or gas leakage that could compromise performance.

QSK45 CM500 and QSK60 CM500

For the QSK45 CM500 and QSK60 CM500 engines, the O-Ring Seal 3640109 is engineered to provide a reliable seal. This is particularly important in these engines, where maintaining a tight seal is essential for optimal performance and longevity. The O-ring’s design ensures it can withstand the operational stresses of these engines, providing a consistent and dependable seal.

QSK50 CM2350 K108 and QSK60 CM850 MCRS

The O-Ring Seal 3640109 also fits the QSK50 CM2350 K108 and QSK60 CM850 MCRS engines. These engines, with their specific design and operational requirements, benefit from the O-ring’s ability to maintain a secure seal under varying conditions. The O-ring’s material and design are chosen to ensure it can endure the unique demands of these engines, providing a critical barrier against leaks.

Each of these engines relies on the O-Ring Seal 3640109 to maintain operational efficiency and reliability, ensuring that the engine’s sealing systems function as intended.

Role of Part 3640109 O-Ring Seal in Engine Systems

The O-Ring Seal, designated as part 3640109, is integral to the reliable operation of various engine components. It ensures the integrity of fluid systems by providing a tight seal that prevents leaks and maintains system pressure.

Fuel System Integration

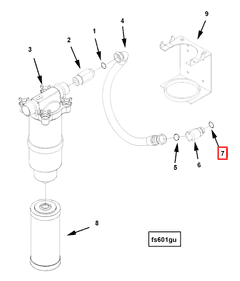

In the fuel system, the O-Ring Seal is employed at connection points such as the fuel transfer pump and the male union elbow. Its role here is to create a secure seal that prevents fuel leakage, which is essential for maintaining the correct fuel pressure and ensuring efficient engine performance. The seal is also used in the connections between the pump and other fuel system components, reinforcing the system’s reliability.

Accessories and Flanges

When it comes to accessories attached to the engine, the O-Ring Seal is often found in the connections to the main engine block or other components. This application ensures that any fluids or gases involved in the accessory’s operation are contained effectively, preventing loss and maintaining operational efficiency.

At flange connections, the O-Ring Seal plays a significant role in sealing the interface between two mating surfaces. This is particularly important in high-pressure or high-temperature environments where even a small leak can lead to significant issues. The seal helps in maintaining the integrity of the connection, ensuring that the flanges perform their intended function without compromise.

Fuel Transfer Applications

In the context of fuel transfer, the O-Ring Seal is utilized in the connections between various components of the fuel transfer system. This includes seals at the interfaces of the fuel transfer pump and the lines that carry fuel to and from the engine. The seal’s ability to conform to the surfaces it contacts ensures a leak-free connection, which is vital for the safe and efficient transfer of fuel.

Overall, the application of the O-Ring Seal in these various engine components underscores its importance in maintaining the operational integrity and efficiency of the engine system.

Conclusion

The Cummins 3640109 O-Ring Seal plays a vital role in ensuring the reliability and efficiency of commercial truck engines. Its design and material properties make it suitable for a wide range of applications, from fuel systems to hydraulic systems, ensuring that seals remain intact under demanding conditions. Proper installation and maintenance of this part are crucial for preventing leaks and maintaining the overall performance of the vehicle.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Michael Hilgers, Electrical Systems and Mechatronics, Second Edition, Springer Vieweg, 2023.

↩ -

Frank Sander, Diesel Mechanics, First Edition, Global Media, 2007.

↩ -

Rob Thompson, Automotive Maintenance: Light Repair, Cengage Learning, 2019.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.