This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3646659 O-Ring Seal is a component designed to ensure the integrity of seals in various systems within commercial trucks. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal (doughnut-shaped) piece of elastomeric material. It functions by being compressed between two or more mating surfaces to create a seal. O-Rings are commonly made from materials such as nitrile rubber, silicone, or fluorocarbon elastomers, chosen for their resistance to various chemicals, temperatures, and pressures 2. The fundamental principle behind O-Ring Seals is their ability to deform under compression, filling the gaps between surfaces to prevent the passage of fluids or gases.

Purpose of the 3646659 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems, such as fuel lines, hydraulic systems, and engine components. Its application is critical in environments where leaks could lead to system failure or reduced efficiency. By providing a reliable seal, the 3646659 O-Ring Seal contributes to the overall performance and safety of the truck.

Key Features of the 3646659 O-Ring Seal

The 3646659 O-Ring Seal is characterized by several key features that make it suitable for its intended applications. These include its material composition, which is designed to withstand the harsh conditions found in commercial truck environments, its precise size to fit specific applications, and its durability, ensuring long-term performance without the need for frequent replacements.

Benefits of Using the 3646659 O-Ring Seal

Utilizing this part offers several advantages. It provides improved sealing performance, reducing the risk of leaks and system failures. Its longevity and reliability in demanding environments contribute to the overall efficiency and safety of truck operations. Additionally, the seal’s design ensures compatibility with various truck systems, making it a versatile component for maintenance and repair.

Installation Considerations

Proper installation of the 3646659 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines for installation include ensuring the mating surfaces are clean and free of debris, using the correct amount of lubrication to facilitate seating, and avoiding over-compression, which can damage the seal. Following these best practices helps maintain the integrity of the seal and the systems it protects 3.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Troubleshooting steps include inspecting the seal for signs of wear or damage, checking the mating surfaces for cleanliness and proper alignment, and ensuring the seal is not over-compressed. Addressing these issues promptly can prevent more significant system failures.

Maintenance Tips

Routine maintenance practices can prolong the lifespan of the 3646659 O-Ring Seal and ensure continued reliable performance. These include regular inspections for signs of wear or damage, cleaning the mating surfaces before reinstallation, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Proper maintenance not only extends the life of the seal but also contributes to the overall reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, ensuring reliability, efficiency, and performance.

Cummins O-Ring Seal 3646659 in Engine Applications

The O-Ring Seal 3646659, manufactured by Cummins, is a critical component in ensuring the integrity and efficiency of various engine systems. This seal is designed to fit seamlessly within the engine architecture of several Cummins models, providing a reliable barrier against leaks and maintaining system pressure.

QSK60 and G Engines

In the QSK60 and G series engines, the O-Ring Seal 3646659 plays a pivotal role in maintaining the integrity of the fuel and lubrication systems. These engines, known for their robust performance and reliability, depend on precise sealing to prevent fluid leaks and maintain optimal pressure levels. The seal is typically used in areas where components interface, such as in fuel injectors, pump connections, and other critical junctures where fluid containment is essential.

CM2358 Engines

The CM2358 engine also benefits from the O-Ring Seal 3646659, particularly in its fuel and coolant systems. This seal ensures that the engine operates efficiently by preventing any unwanted fluid loss, which could otherwise lead to performance degradation or system failure. Its placement in high-pressure zones of the engine ensures that the seal can withstand the operational stresses and maintain its sealing properties over time.

K110 Engines

In the K110 engine, the O-Ring Seal 3646659 is utilized in various applications to maintain the seal in the engine’s hydraulic and lubrication systems. This seal is crucial in ensuring that the engine’s internal components are protected from contaminants and that the system’s pressure is maintained. Its design allows it to fit snugly in the designated areas, providing a dependable barrier against leaks and ensuring the longevity of the engine’s performance.

Each of these engines, while distinct in their applications and design, relies on the O-Ring Seal 3646659 to maintain operational efficiency and reliability. The seal’s ability to fit precisely and perform consistently across different engine models underscores its importance in the overall engine system.

Role of Part 3646659 O-Ring Seal in Various Engine Systems

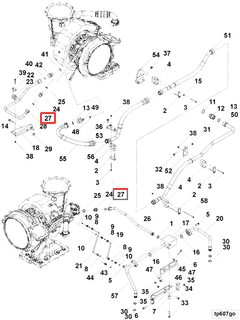

Plumbing Systems

In plumbing systems, the O-Ring Seal (Part 3646659) is utilized to ensure a tight seal between various components, preventing leaks and maintaining system integrity. It is commonly placed in joints and connections where fluid dynamics are significant, such as between pipes and fittings. The seal helps in maintaining pressure and preventing the escape of fluids, which is essential for the efficient operation of the plumbing system.

Turbocharger

Within the turbocharger, the O-Ring Seal (Part 3646659) plays a significant role in sealing the connections between the turbocharger housing and the engine. This ensures that the pressurized air from the turbocharger is effectively delivered to the engine’s intake system without any loss of pressure. The seal is particularly important in maintaining the turbocharger’s efficiency and the overall performance of the engine.

Turbocharger Intercooler Gasket Kit

In a turbocharger intercooler gasket kit, the O-Ring Seal (Part 3646659) is used to create a secure seal between the intercooler and its mounting points. This is vital for the intercooler to function correctly by cooling the compressed air from the turbocharger before it enters the engine. A proper seal ensures that cooled air is efficiently delivered to the engine, enhancing combustion efficiency and power output.

Turbocharger Kit

When incorporated into a turbocharger kit, the O-Ring Seal (Part 3646659) is essential for sealing various connections within the kit, such as between the turbocharger and the manifold, or within the turbocharger itself. This ensures that the turbocharger kit operates as intended, providing the necessary boost to the engine without any air leaks, which could compromise performance.

Water Transfer Tube

In systems utilizing a water transfer tube, the O-Ring Seal (Part 3646659) is employed to seal the connections where the tube interfaces with other components. This is important for maintaining the integrity of the water transfer system, ensuring that water is effectively circulated for cooling purposes without any leaks. The seal helps in preserving the system’s efficiency and reliability.

Conclusion

The Cummins 3646659 O-Ring Seal is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design, material composition, and precise fit make it an essential part for ensuring the integrity of seals, preventing leaks, and maintaining system efficiency. Proper installation, maintenance, and understanding of its role in different applications are crucial for maximizing the performance and reliability of truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.