This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3648162 Dust Seal is designed to prevent contaminants from entering sensitive areas of commercial trucks. It plays a significant role in maintaining the integrity and performance of truck systems by safeguarding internal components from dust, dirt, and other particulates.

Basic Concepts of Dust Seals

Dust seals, also known as lip seals, are mechanical components used to prevent the ingress of contaminants into moving parts. They create a barrier between the external environment and the internal components of a system. Typically made from elastomeric materials, dust seals are designed to fit snugly around shafts or housings, providing a seal that is both flexible and durable. Their application is widespread in mechanical systems where moving parts are exposed to the environment 1.

Purpose of the Cummins 3648162 Dust Seal

This Cummins part is positioned in areas where shafts or rotating parts are exposed to the external environment. By doing so, it helps maintain the cleanliness of the internal components, which is vital for the efficient operation and longevity of the truck’s systems 2.

Key Features

The 3648162 is characterized by its specific design and material properties that enhance its performance and durability. It is made from high-quality elastomeric materials that offer excellent resistance to wear and environmental factors. The seal’s design includes a lip that contacts the shaft or housing, providing a tight seal that is effective at blocking contaminants while allowing for smooth operation 3.

Benefits

Using this Dust Seal offers several advantages. It contributes to improved component longevity by keeping contaminants out, which reduces the wear and tear on internal parts. This, in turn, leads to reduced maintenance needs, as the components are less likely to fail prematurely. Additionally, the seal enhances overall system efficiency by ensuring that the components operate in a clean environment, which is crucial for optimal performance 4.

Installation Considerations

Proper installation of the 3648162 is important for ensuring its optimal performance and longevity. It should be installed in a clean environment to prevent contaminants from being trapped between the seal and the shaft or housing. The seal should be lubricated according to the manufacturer’s recommendations to ensure smooth operation. Careful attention should be paid to the alignment and seating of the seal to ensure a proper fit and effective sealing.

Troubleshooting Common Issues

Typical problems associated with dust seals include leaks, wear, and failure to seat properly. These issues can often be diagnosed by visual inspection or by observing symptoms such as increased wear on components or contamination within the system. Resolving these issues may involve replacing the seal, ensuring proper lubrication, or addressing alignment issues.

Maintenance Tips

Regular maintenance of the 3648162 is important for prolonging its service life and maintaining its effectiveness. This includes periodic inspection for signs of wear or damage, ensuring proper lubrication, and cleaning the area around the seal to prevent the accumulation of contaminants. Following the manufacturer’s recommendations for maintenance intervals and procedures will help ensure the seal continues to perform effectively.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to excellence is reflected in its diverse product range and its focus on meeting the needs of its customers through continuous improvement and technological advancement.

Cummins Dust Seal 3648162 Compatibility

The Cummins Dust Seal part number 3648162 is designed to fit a range of engines, providing a critical barrier against dust, debris, and other contaminants that could compromise engine performance. This part is engineered to ensure a tight seal, which is essential for maintaining the integrity of the engine’s internal components.

Compatible Engines

The Dust Seal 3648162 is compatible with the following engines:

- GTA38 G CMEICS G116C

- K19

- K38

- K50

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QST30 CM2350 T101

- QST30 CM552

Grouping of Compatible Engines

The engines listed can be grouped based on their model series and configurations:

- KTA Series: KTA19GC, KTA19GC CM558, KTA38GC CM558

- QSK Series: QSK38 CM2150 MCRS, QSK38 CM850 MCRS, QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QST Series: QST30 CM2350 T101, QST30 CM552

- Other Models: GTA38 G CMEICS G116C, K19, K38, K50

This Dust Seal is a versatile component that fits seamlessly into the specified engines, ensuring that they operate efficiently and reliably by preventing the ingress of harmful particles.

Role of Part 3648162 Dust Seal in Engine Systems

The part 3648162 Dust Seal is an essential component in maintaining the integrity and efficiency of various engine systems. It is strategically positioned to prevent contaminants from entering sensitive areas, thereby ensuring smooth operation and longevity of the engine.

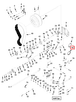

Integration with Engine Components

-

Cover and Gear Housing: The Dust Seal is often installed between the cover and the gear housing. This placement is vital for protecting the internal components from dust and debris that could otherwise cause wear and tear.

-

Front Gear Cover and Mounting: When integrated with the front gear cover and its mounting, the Dust Seal helps in maintaining a clean environment around the gears, which is essential for precise gear operation and reduced friction.

-

Front Seal Crank Kit: In conjunction with the front seal crank kit, the Dust Seal plays a role in safeguarding the crankshaft from external particles. This protection is important for the crankshaft’s smooth rotation and overall engine performance.

-

Lower Engine Gasket Kit and Set: The Dust Seal works in tandem with the lower engine gasket kit and set to create a sealed environment. This sealing is important for maintaining proper pressure and preventing leaks within the lower section of the engine.

-

Overhaul Gasket Set and Kit: During engine overhauls, the Dust Seal is a key component in the overhaul gasket set and kit. It ensures that all refurbished or replaced parts are well-protected from environmental contaminants post-overhaul.

-

Support and Front Engine: The Dust Seal also contributes to the stability and efficiency of the front engine support. By keeping the front engine area clean, it aids in the consistent performance of the engine’s front-end components.

Conclusion

In summary, the part 3648162 Dust Seal is a fundamental element in the maintenance and operation of various engine systems. Its role in preventing contamination and ensuring component integrity is indispensable for the overall health and efficiency of the engine.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Kasab, John, and Strzelec, Andrea. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.