3690234

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

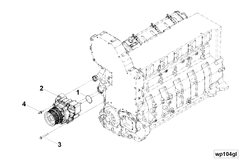

The Cummins 3690234 O Ring Seal is a component designed for use in commercial trucks. Its purpose is to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid systems and preventing leaks. This seal is particularly relevant in environments where durability and efficiency are paramount.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a circular section of elastomer with a round cross-section. It functions by creating a seal when compressed within a groove, blocking the passage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Role of the Cummins 3690234 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring the sealing of certain components within the engine or other systems. It is typically placed in grooves where it can compress and create a barrier to fluid or gas flow. This seal is integral to maintaining system pressure and preventing leaks, which can affect the performance and efficiency of the truck 2.

Key Features

The Cummins 3690234 O Ring Seal is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the operational stresses and temperatures encountered in commercial truck applications. The seal is also engineered with specific design specifications to ensure a snug fit and effective sealing. Its durability is a notable feature, allowing it to maintain its integrity over extended periods of use 3.

Benefits

The use of the Cummins 3690234 O Ring Seal offers several benefits. It provides improved sealing efficiency, which is crucial for maintaining system performance. Its longevity ensures that it can withstand the rigors of commercial truck operation without frequent replacements. Additionally, the seal contributes to the overall reliability of the system by preventing leaks and maintaining system pressure 4.

Troubleshooting and Maintenance

Identifying common issues with O Ring Seals, such as leaks or degradation, is important for maintaining truck performance. Troubleshooting may involve inspecting the seal for signs of wear or damage and ensuring it is properly seated in its groove. Maintenance practices include regular inspection and replacement of the seal as needed to ensure optimal performance and longevity.

Compatibility with Various Engine Models

This Cummins part is compatible with several Cummins engine models, including:

- ISX15 CM2350 X101

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2350 X134B

In these engines, the O Ring Seal 3690234 is essential for maintaining the integrity of the engine’s sealing system, providing a reliable barrier against leaks and ensuring optimal performance.

Integration with Overhaul Kit

The O Ring Seal, part 3690234, is instrumental in overhaul kits. It ensures that all components within the kit are securely sealed, preventing leaks and maintaining the integrity of the system. This seal is typically used in areas where fluid dynamics are significant, such as around rotating shafts or between mating surfaces that require a tight seal.

Application in Pumps

In pump systems, the O Ring Seal plays a significant role in maintaining the efficiency and reliability of the pump. It is often placed in the pump housing to prevent fluid leakage, ensuring that the pump operates within its designed parameters. This seal helps in maintaining the pressure differentials necessary for the pump to function correctly.

Use in Water Systems

For water systems within an engine, the O Ring Seal is essential for preventing water leaks, which can lead to corrosion and other forms of damage. It is commonly used in areas where water flows through the engine, such as around coolant passages and water jackets. The seal ensures that water remains contained within its intended pathways, enhancing the overall cooling efficiency of the engine.

Specific Role in Water Pump

In the context of a water pump, the O Ring Seal is used to ensure that the pump can effectively circulate coolant without any leaks. It is typically installed around the impeller shaft and other critical points where the pump interfaces with the engine block or other components. This seal is vital for maintaining the pump’s performance and longevity.

Importance in Water Pump Kit

When included in a water pump kit, the O Ring Seal serves multiple functions. It not only ensures that the new water pump is installed correctly but also that it operates efficiently from the moment it is put into service. The seal helps in creating a barrier against coolant leaks, which is essential for the proper functioning of the engine’s cooling system.

Conclusion

The Cummins 3690234 O Ring Seal is a critical component in the maintenance and operation of commercial trucks. Its role in ensuring the integrity of fluid systems, preventing leaks, and maintaining system pressure is vital for the performance and efficiency of the truck. Regular maintenance and timely replacement of this part are essential for the longevity and reliability of the vehicle’s systems.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.