This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3695976 O-Ring Seal is a component designed for use in commercial trucks. It serves to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid and gas pathways. This seal is integral to maintaining the efficiency and performance of the truck’s engine and other mechanical systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section. It functions by creating a seal when compressed within a groove, preventing the passage of fluids or gases between mating surfaces. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including automotive, aerospace, and industrial machinery 1.

Purpose of the Cummins 3695976 O-Ring Seal

The Cummins 3695976 O-Ring Seal plays a specific role in the operation of a truck. It is designed to ensure a tight seal in the engine or other systems where fluid or gas containment is necessary. By preventing leaks, the seal contributes to the overall efficiency and reliability of the truck’s mechanical systems 2.

Key Features

The Cummins 3695976 O-Ring Seal is characterized by several key features. It is made from a durable elastomer material that provides resistance to a range of operating conditions. The seal is designed to withstand high pressures and temperatures, ensuring longevity and consistent performance. Its precise dimensions and tolerances are critical for proper fit and function within the designated grooves 3.

Benefits of Using the Cummins 3695976 O-Ring Seal

Utilizing the Cummins 3695976 O-Ring Seal offers several advantages. It provides improved sealing efficiency, which is vital for maintaining system integrity and performance. The seal’s durability ensures a longer service life, reducing the frequency of replacements. Additionally, its resistance to various operating conditions, including exposure to chemicals and extreme temperatures, enhances the reliability of the truck’s systems 4.

Installation Process

Proper installation of the Cummins 3695976 O-Ring Seal is crucial for its effectiveness. The process involves cleaning the groove where the seal will be placed to remove any debris or contaminants. The seal should be lubricated before insertion to facilitate smooth placement and to prevent damage. Careful handling is required to avoid distorting the seal, ensuring it sits correctly within the groove for optimal performance.

Common Issues and Troubleshooting

Common problems associated with O-Ring Seals include leaks and degradation over time. Leaks may occur due to improper installation, damage to the seal, or wear and tear. Degradation can result from exposure to incompatible fluids, extreme temperatures, or mechanical stress. Troubleshooting involves inspecting the seal for signs of damage, ensuring proper installation, and replacing the seal if necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3695976 O-Ring Seal is important for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning the seal and its groove to remove contaminants, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Proper maintenance helps prevent leaks and ensures the continued efficiency of the truck’s systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins O-Ring Seal 3695976 Compatibility

The Cummins O-Ring Seal part number 3695976 is designed to fit seamlessly within a variety of engine configurations. This O-Ring Seal is engineered to provide a reliable seal in critical areas, ensuring that the engine operates efficiently and safely. Below is a detailed description of how this O-Ring Seal fits with the specified engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The O-Ring Seal 3695976 is compatible with both the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. This seal is strategically placed in areas where it can effectively prevent leaks, ensuring that the engine maintains optimal pressure and performance. Its placement is crucial in maintaining the integrity of the engine’s sealing system.

ISG12 G CMOH6.0 G111

For the ISG12 G CMOH6.0 G111 engine, the O-Ring Seal 3695976 is designed to fit in specific components that require a high level of sealing. This engine model benefits from the precision engineering of this O-Ring, which helps in maintaining the engine’s operational efficiency and longevity.

QSG12 CM2880 G112

The QSG12 CM2880 G112 engine also utilizes the O-Ring Seal 3695976 in key areas where sealing is critical. This seal ensures that there are no leaks, which is essential for the engine’s performance and reliability. Its design allows it to fit snugly in the designated areas, providing a robust barrier against fluid and gas leaks.

QSG12/X12 CM2350 G110 and X12 CM2670 X121B

The O-Ring Seal 3695976 is also compatible with the QSG12/X12 CM2350 G110 and X12 CM2670 X121B engines. In these engines, the seal is placed in locations where it can effectively prevent leaks, ensuring that the engine operates smoothly. Its design and material properties make it suitable for the demanding conditions within these engines, providing a reliable seal that enhances overall engine performance.

By integrating the O-Ring Seal 3695976 into these engines, Cummins ensures that the engines maintain their operational integrity, reducing the risk of leaks and enhancing overall performance.

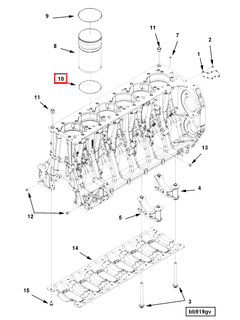

Role of Part 3695976 O-Ring Seal in Engine Systems

The part 3695976 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Within the Cylinder Block, this O-Ring Seal ensures that the combustion process remains contained, preventing any leakage of gases or fluids that could compromise engine performance. It is positioned in areas where different components interface, such as between the cylinder block and the cylinder head, to create a tight seal that withstands high pressures and temperatures.

In addition to its role in the cylinder block, the O-Ring Seal is also employed in other critical junctions within the engine. For instance, it is used in the Fuel Injection System to seal connections between the fuel injectors and the fuel rail, ensuring that fuel delivery is precise and leak-free. This seal is vital for maintaining the correct fuel pressure and preventing any fuel from escaping, which could lead to inefficient combustion and increased emissions.

Furthermore, within the Cooling System, the O-Ring Seal is utilized in the connections between the engine block and the coolant passages. This ensures that coolant flows smoothly through the system without any leaks, which is essential for regulating engine temperature and preventing overheating.

In the Lubrication System, the O-Ring Seal plays a part in maintaining the integrity of oil passages and connections. By ensuring that oil flows correctly through the engine, it helps in reducing friction between moving parts, thereby enhancing the longevity and performance of the engine.

Overall, the part 3695976 O-Ring Seal is a small yet significant component that contributes to the reliable operation of various engine systems by providing essential seals at critical junctions.

Conclusion

The Cummins 3695976 O-Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its role in ensuring the integrity of fluid and gas pathways within the engine systems cannot be overstated. By providing reliable seals at critical junctions, this part contributes to the overall efficiency, performance, and longevity of the engine. Proper installation, regular maintenance, and understanding its compatibility with various engine configurations are essential for maximizing the benefits of this O-Ring Seal.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.