This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3779750 O-Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its purpose is to prevent leaks and maintain system efficiency. The significance of this O-Ring Seal lies in its ability to contribute to the reliable operation of trucks by ensuring that fluids and gases remain contained within their designated pathways.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a circular section of elastomer. Its construction involves a doughnut shape that creates a seal when compressed between two surfaces. Common materials used in O-Ring Seals include nitrile rubber, silicone, and fluorocarbon. These materials are chosen for their flexibility, resistance to various chemicals, and ability to maintain a seal under pressure 1. O-Ring Seals function by deforming slightly when compressed, which allows them to fill any irregularities on mating surfaces and create an effective seal.

Role of the 3779750 O-Ring Seal in Truck Operation

The 3779750 O-Ring Seal plays a specific role in the operation of a truck by ensuring the integrity of seals in various systems or components. It is commonly associated with fuel systems, hydraulic systems, and engine components where maintaining a seal is crucial for performance and safety. By preventing leaks, the O-Ring Seal helps maintain system pressure and efficiency, contributing to the overall reliability of the truck.

Key Features of the 3779750 O-Ring Seal

The 3779750 O-Ring Seal is characterized by its design and material properties. It is made from a durable elastomer that offers resistance to a wide range of temperatures and chemicals commonly encountered in truck operations. The seal’s design ensures it can accommodate dynamic movements and vibrations typical in truck environments. Unique characteristics such as its specific durometer rating and cross-sectional dimensions enhance its performance by providing an optimal balance between flexibility and sealing capability 2.

Benefits of Using the 3779750 O-Ring Seal

Utilizing the 3779750 O-Ring Seal offers several benefits. It provides improved sealing efficiency, which helps in maintaining system integrity and performance. The seal’s durability ensures long-term reliability, reducing the frequency of replacements. Additionally, its resistance to various operating conditions, including extreme temperatures and exposure to chemicals, enhances its suitability for use in commercial trucks.

Installation Considerations

When installing the 3779750 O-Ring Seal, it is important to follow guidelines and best practices to ensure proper function. This includes handling the seal carefully to avoid damage, ensuring it is properly seated in the groove, and adhering to any torque specifications for components it is associated with. Proper installation is key to achieving the seal’s intended performance and longevity.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Troubleshooting steps may include inspecting the seal for signs of wear or damage, checking for proper seating, and ensuring that the mating surfaces are clean and free of contaminants. Addressing these issues promptly can help maintain system efficiency and prevent more significant problems.

Maintenance and Replacement

To ensure continued reliable performance, periodic maintenance and replacement of the 3779750 O-Ring Seal are recommended. Regular inspections can help identify signs of wear or degradation before they lead to failure. Replacement should be carried out according to the manufacturer’s guidelines or as part of routine maintenance schedules to prevent unexpected downtime and ensure the truck operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines and components designed to meet the demanding requirements of commercial vehicles, ensuring reliability, performance, and efficiency.

O-Ring Seal 3779750 in Cummins Engines

The O-Ring Seal part number 3779750, manufactured by Cummins, is a critical component in various engine systems. This seal is designed to provide a reliable barrier against leaks, ensuring that fluids remain within their designated pathways. Its application spans across multiple engine models, enhancing the overall efficiency and longevity of the engine.

Application in ISV Engines

In the ISV (Intelligent Series Vehicle) engines by Nissan, the O-Ring Seal 3779750 plays a pivotal role in maintaining the integrity of the engine’s hydraulic and lubrication systems. This seal is strategically placed in areas where fluid containment is crucial, such as in the fuel injection system, transmission, and various hydraulic circuits. Its precision fit ensures that there are no leaks, which could otherwise lead to performance degradation or engine damage.

Grouping of Engines

The O-Ring Seal 3779750 is compatible with a range of Cummins engines, including but not limited to, the following models:

-

Cummins B Series Engines: These engines are known for their robust performance and reliability. The O-Ring Seal ensures that the internal hydraulic systems operate smoothly without any fluid loss.

-

Cummins C Series Engines: Widely used in various industrial applications, these engines benefit from the O-Ring Seal’s ability to maintain pressure and prevent leaks in critical areas.

-

Cummins QSX Engines: These high-performance engines require precise sealing to handle the demands of heavy-duty applications. The O-Ring Seal 3779750 is engineered to meet these stringent requirements.

Each of these engines relies on the O-Ring Seal to maintain operational efficiency and prevent costly downtime due to leaks. The seal’s design and material ensure it can withstand the high pressures and temperatures typical in engine environments, providing a dependable solution for fluid containment.

Role of Part 3779750 O-Ring Seal in Engine Systems

The part 3779750 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine components.

Pressure Sensing Tube

In the context of the pressure sensing tube, the O-Ring Seal ensures a tight and reliable connection between the tube and its mating surfaces. This seal prevents any leakage of pressurized fluids or gases, which is essential for accurate pressure readings. Accurate pressure data is vital for the engine control unit (ECU) to make precise adjustments to fuel delivery and ignition timing, thereby optimizing engine performance and efficiency.

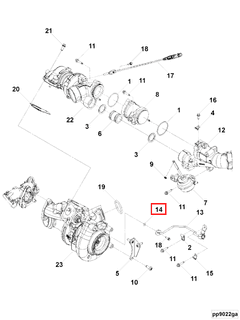

Turbocharger

When integrated into a turbocharger system, the O-Ring Seal plays a significant role in sealing the connections between the turbocharger and its associated piping. This seal is responsible for maintaining the boost pressure generated by the turbocharger. Any compromise in this seal can lead to a loss of boost pressure, resulting in reduced engine power and efficiency. Additionally, it helps in preventing the ingress of contaminants into the turbocharger, which can cause premature wear and failure.

Turbocharger Kit

In a turbocharger kit, which often includes multiple components such as intercoolers, wastegates, and additional piping, the O-Ring Seal is used extensively to ensure all connections are leak-free. This is particularly important in high-performance applications where even minor leaks can significantly impact the overall system efficiency. The seal ensures that the pressurized air from the turbocharger is delivered efficiently to the engine, enhancing both power output and fuel economy.

Conclusion

The Cummins 3779750 O-Ring Seal is a vital component in the maintenance and operation of commercial truck systems. Its role in preventing leaks and maintaining system efficiency is crucial for the reliable operation of trucks. The seal’s design and material properties ensure it can withstand the demanding conditions of truck operations, providing long-term reliability and performance. Proper installation, maintenance, and timely replacement of this part are essential to ensure the continued efficiency and reliability of truck systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.