This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3866096 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the engine and component manufacturing industry, produces this O-Ring Seal to meet the demanding requirements of heavy-duty applications. This seal is integral to maintaining the integrity of various systems within commercial trucks, ensuring they operate efficiently and reliably 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals play a role in preventing the leakage of fluids and gases by filling the gap between mating surfaces. They operate under compression, which allows them to conform to the surfaces they seal against, providing a barrier that is both flexible and durable 2.

Purpose of the 3866096 O-Ring Seal in Truck Operations

The 3866096 O-Ring Seal serves a specific function within the operation of commercial trucks. It is positioned in areas where fluid or gas sealing is required, such as in engine components, fuel systems, or hydraulic systems. By creating a reliable seal, it helps maintain system pressure, prevent leaks, and ensure the efficient operation of the truck’s systems 1.

Key Features of the 3866096 O-Ring Seal

The design and material characteristics of the 3866096 O-Ring Seal make it well-suited for heavy-duty applications. It is crafted from materials that offer durability, resistance to a wide range of chemicals, and the ability to withstand various temperature ranges. These features ensure that the seal can perform effectively under the demanding conditions encountered in commercial truck operations 3.

Benefits of Using the 3866096 O-Ring Seal

Utilizing the 3866096 O-Ring Seal in commercial trucks offers several advantages. It contributes to improved system reliability by ensuring seals remain intact under pressure. This results in reduced maintenance needs, as the seal is designed to withstand the rigors of heavy-duty use. Additionally, its performance in demanding conditions enhances the overall efficiency and longevity of the truck’s systems 1.

Installation Considerations

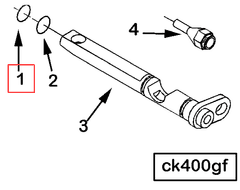

Proper installation of the 3866096 O-Ring Seal is vital for ensuring optimal performance and longevity. Cummins provides guidelines for installation, which may include the use of specific tools or procedures to ensure the seal is correctly positioned and compressed. Following these guidelines helps maintain the integrity of the seal and the systems it protects 1.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, including the 3866096, can arise from improper installation, exposure to incompatible chemicals, or physical damage. Identifying these issues early can prevent more significant problems. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, ensuring it is correctly installed, and verifying that it is compatible with the fluids and gases it is intended to seal 2.

Maintenance Tips

Regular inspection and maintenance of the 3866096 O-Ring Seal are recommended to prevent failures and extend its service life. This includes checking for signs of wear, ensuring it remains properly seated, and replacing it if any damage is detected. Adhering to a maintenance schedule helps maintain the seal’s effectiveness and the overall performance of the truck’s systems 1.

Cummins: A Brief Overview

Cummins is a manufacturer with a strong reputation in the industry for quality and innovation in engine and component manufacturing. With a history of producing reliable and high-performance parts, Cummins is committed to advancing technology and meeting the needs of its customers. This commitment is reflected in the design and performance of the 3866096 O-Ring Seal, which is engineered to provide durable and effective sealing solutions for commercial trucks 3.

Compatibility with Cummins Engines

The 3866096 O-Ring Seal is designed to fit seamlessly within a variety of Cummins engine models. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently.

K19 Series

The K19 series engines benefit from the 3866096, which is engineered to fit perfectly within the engine’s design. This seal is essential for maintaining the pressure and preventing any fluid or gas from escaping, ensuring the engine’s longevity and performance.

KTA19GC and KTA19GC CM558

The KTA19GC and KTA19GC CM558 engines also utilize the 3866096. This seal is specifically designed to fit the unique requirements of these engines, providing a reliable seal that can withstand the high pressures and temperatures typical of these models.

QSB5.9 CM850

The QSB5.9 CM850 engine is another model that is compatible with the 3866096. This seal is critical for maintaining the engine’s sealing integrity, ensuring that it operates efficiently and without leaks.

X15 CM2350 X116B

Lastly, the X15 CM2350 X116B engine is designed to work with the 3866096. This seal is engineered to fit the specific needs of this engine, providing a reliable and durable solution for maintaining the engine’s sealing system.

Role of Part 3866096 O-Ring Seal in Engine Systems

The 3866096 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions.

In the banjo connector screw system, the O-Ring Seal prevents fluid leaks, maintaining consistent pressure and flow within the hydraulic circuits. This is essential for the proper operation of brake systems and other hydraulic components.

Within the block and cylinder assemblies, the O-Ring Seal ensures that combustion gases remain contained, enhancing engine performance and efficiency. It also plays a role in the cylinder kit block by sealing the interfaces between components, preventing oil and fuel leaks that could lead to engine damage.

The breather system benefits from the O-Ring Seal by ensuring that the crankcase ventilation system operates without leaks, which helps in maintaining optimal pressure levels and reducing contaminants within the engine.

In the camshaft area, the O-Ring Seal is used to secure seals around the camshaft bearings, preventing oil leaks and ensuring smooth operation of the valve train.

The heat exchanger relies on the O-Ring Seal to maintain the integrity of the cooling system, ensuring that coolant flows efficiently without leaks, which is vital for engine temperature regulation.

For the fuel filter and fuel connector adapter, the O-Ring Seal is essential in creating a tight seal that prevents fuel leaks, ensuring a consistent fuel supply to the engine.

In the male union connections, the O-Ring Seal provides a reliable seal for fluid transfer systems, whether for oil, fuel, or coolant, ensuring system integrity and performance.

The base parts and performance parts often incorporate the O-Ring Seal to ensure that all connections and interfaces are leak-free, contributing to the overall reliability and performance of the engine.

Lastly, in the piston cooling nozzle system, the O-Ring Seal ensures that the oil jets are directed accurately and without leaks, which is crucial for maintaining piston temperature and engine longevity.

Conclusion

The 3866096 O-Ring Seal plays a vital role in the operation and maintenance of commercial trucks by ensuring the integrity of various systems. Its design and material characteristics make it well-suited for heavy-duty applications, contributing to improved system reliability, reduced maintenance needs, and enhanced overall efficiency and longevity of the truck’s systems 123.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ ↩ ↩ ↩ ↩ ↩ -

Introduction to Engine Valvetrains, Yushu Wang, SAE International, 2007.

↩ ↩ ↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.