This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3866102 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at enhancing the performance and reliability of trucks. This Cummins part plays a role in ensuring the integrity of seals within various truck systems 1.

Basic Concepts of O-Ring Seals

O-Ring Seals are circular rings, typically made from elastomers, that create seals in mechanical systems. They operate by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Rings are widely used due to their simplicity, effectiveness, and versatility in various applications, including automotive and heavy-duty truck systems 2.

Purpose of the 3866102 O-Ring Seal in Truck Operations

In commercial trucks, the 3866102 O-Ring Seal serves a specific function within the truck’s systems. It is associated with components where fluid or gas sealing is required to maintain system efficiency and prevent leaks. This O-Ring Seal contributes to the reliable operation of the truck by ensuring that seals remain intact under various operating conditions 3.

Key Features of the 3866102 O-Ring Seal

The 3866102 O-Ring Seal is designed with specific characteristics that enhance its effectiveness and durability in truck applications. Its material composition allows it to withstand a range of temperatures and pressures, while its design ensures a snug fit within the designated grooves. These features contribute to its ability to provide a reliable seal in demanding environments 4.

Benefits of Using the 3866102 O-Ring Seal

Utilizing the 3866102 O-Ring Seal offers several advantages. It provides improved sealing performance, which is vital for maintaining the efficiency of truck systems. Its durability ensures longevity, reducing the frequency of replacements. Additionally, its resistance to various environmental factors enhances its reliability in diverse operating conditions 5.

Installation Considerations

Proper installation of the 3866102 O-Ring Seal is crucial for its optimal performance and longevity. Guidelines recommend ensuring the groove is clean and free of debris before installation. The O-Ring should be lubricated to facilitate easy insertion and to prevent damage. Careful handling during installation helps maintain the integrity of the seal 6.

Troubleshooting Common Issues

Common problems with O-Ring Seals in truck applications can include leaks or failure to create a seal. Troubleshooting steps may involve inspecting the O-Ring for signs of wear or damage, checking the groove for cleanliness and proper sizing, and ensuring correct installation practices were followed. Addressing these issues promptly can prevent more significant problems 7.

Maintenance Tips

Regular maintenance and inspection of the 3866102 O-Ring Seal are recommended to prevent failures and extend its service life. This includes checking for signs of wear or degradation, ensuring it remains properly seated in the groove, and replacing it according to the manufacturer’s guidelines or when signs of failure are observed 8.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products and systems designed to enhance truck performance and reliability. With a history of innovation and quality, Cummins has established a strong reputation for producing parts that meet the demanding requirements of commercial truck operations 9.

Cummins O-Ring Seal 3866102 Compatibility

The Cummins O-Ring Seal part number 3866102 is designed to fit seamlessly within various engine models, ensuring a reliable seal to prevent leaks and maintain engine efficiency. This O-Ring Seal is compatible with the following engines:

- 6B5.9

- 6C8.3

- QSB5.9 CM850

- QSB6.7 M CM2250

For the 6B5.9 and 6C8.3 engines, the O-Ring Seal 3866102 is engineered to fit critical areas where sealing is essential, such as in fuel injectors, hydraulic systems, and other fluid pathways. This ensures that the engines maintain optimal performance and longevity.

In the QSB5.9 CM850 and QSB6.7 M CM2250 engines, the O-Ring Seal 3866102 is also crucial for maintaining the integrity of the engine’s sealing systems. These engines, being part of the QSB series, often require robust sealing solutions to handle the demanding conditions of heavy-duty applications. The O-Ring Seal 3866102 provides the necessary durability and performance to meet these requirements.

By ensuring a proper fit and function, the O-Ring Seal 3866102 plays a vital role in the overall reliability and efficiency of these Cummins engines 10.

Role of Part 3866102 O-Ring Seal in Engine Systems

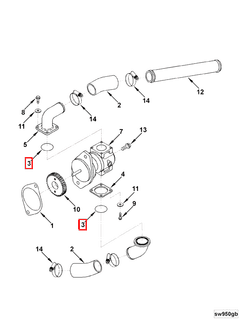

The part 3866102 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine components. In the Kit, this O-Ring Seal is often utilized to create a tight seal between different parts, preventing leaks and ensuring that fluids or gases remain contained within their designated pathways. This is particularly important in maintaining the performance and longevity of the engine.

When considering On Board Spares, the inclusion of the 3866102 O-Ring Seal is a strategic move. It allows for quick replacements in the event of wear or damage, minimizing downtime and ensuring that the engine can be swiftly returned to operational status. This is especially valuable in environments where immediate repairs are necessary to avoid extended periods of inactivity.

In the Raw Water Pump and Sea Water Pump, the 3866102 O-Ring Seal plays a significant role in sealing the connections between the pump housing and the impeller. This seal is vital for maintaining the pump’s efficiency by preventing water leakage, which could lead to reduced performance or complete failure of the pump. The seal ensures that the water flow is consistent and unimpeded, which is essential for the cooling systems reliant on these pumps.

Lastly, within the Upper Engine Gasket Kit, the 3866102 O-Ring Seal is used to ensure that the gaskets form a perfect seal with the engine block and other mating surfaces. This is important for preventing coolant or oil leaks, which could lead to engine overheating or contamination. The seal helps maintain the pressure integrity of the engine’s cooling and lubrication systems, contributing to overall engine health and performance 11.

Conclusion

The 3866102 O-Ring Seal is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its role in ensuring the integrity of seals across various engine systems underscores its importance in maintaining engine efficiency, reliability, and longevity. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential practices to maximize the benefits of this Cummins part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021618, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.