This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

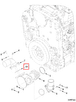

The Cummins 3897381 O-Ring Seal is a critical component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to prevent leaks and maintain system efficiency, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section. It functions by creating a seal between two or more parts, typically in dynamic or static applications. O-Rings are widely used in mechanical systems to prevent fluid or gas leakage, ensuring the system operates within specified parameters 2.

Purpose of the Cummins 3897381 O-Ring Seal

This Cummins part is specifically designed to fit within the engine or other fluid systems of commercial trucks. It plays a role in maintaining the seal at various connection points, which helps in preserving the pressure and purity of the fluids circulating within the system. Its placement is critical in areas where fluid dynamics are significant, such as around fittings, flanges, or within the engine block 3.

Key Features

The Cummins 3897381 O-Ring Seal is constructed from high-quality elastomer materials, chosen for their durability and resistance to the operating conditions found in commercial trucks. Its design specifications include precise dimensions to ensure a snug fit and effective sealing. The material composition allows it to withstand temperature variations, chemical exposure, and mechanical stress, enhancing its performance in demanding environments 4.

Benefits

Using the Cummins 3897381 O-Ring Seal provides several advantages. It offers improved sealing efficiency, which helps in maintaining system pressure and reducing the risk of leaks. Its durability ensures a longer service life, minimizing the need for frequent replacements. Additionally, its resistance to various operating conditions makes it a reliable component in the harsh environments typical of commercial truck operations 5.

Installation Process

Proper installation of the Cummins 3897381 O-Ring Seal involves several steps to ensure correct fitting. First, the mating surfaces should be clean and free of debris. The O-Ring should be lubricated with a compatible fluid to facilitate insertion and prevent damage. It is then carefully placed into the groove, ensuring it is not twisted or damaged. Finally, the components are assembled, and the system is checked for proper sealing 6.

Common Issues and Troubleshooting

Common issues with O-Ring Seals include leaks due to wear, improper installation, or exposure to incompatible fluids. Troubleshooting may involve inspecting the O-Ring for signs of damage, ensuring correct installation, and verifying compatibility with system fluids. Replacement may be necessary if the O-Ring shows signs of degradation or if leaks persist after troubleshooting 7.

Maintenance Tips

Regular maintenance of the Cummins 3897381 O-Ring Seal involves periodic inspection for signs of wear or damage. It is recommended to follow manufacturer guidelines for inspection intervals. If the O-Ring shows signs of deterioration, it should be replaced to maintain system integrity. Keeping the mating surfaces clean and ensuring proper installation during maintenance procedures will contribute to the longevity of the seal 8.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technical expertise make it a trusted partner for commercial vehicle operators worldwide 9.

Cummins O-Ring Seal 3897381 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3897381 is designed to fit seamlessly with several engine models, ensuring a reliable seal in various applications. This O-Ring is engineered to provide an effective barrier against leaks, maintaining the integrity of the engine’s system.

K19 and K38 Engines

The O-Ring Seal 3897381 is compatible with the K19 and K38 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The O-Ring fits precisely in areas where it is needed to prevent fluid leaks, ensuring the engine operates efficiently and safely 10.

K50 Engine

The K50 engine also benefits from the O-Ring Seal 3897381. This engine is designed for high-performance and durability, making it suitable for demanding industrial applications. The O-Ring ensures that critical components remain sealed, preventing any loss of hydraulic or lubrication fluids 11.

QSK19 CM850 MCRS Engine

The QSK19 CM850 MCRS engine is another model that can utilize the O-Ring Seal 3897381. This engine is engineered for superior power and efficiency, often used in marine and power generation sectors. The O-Ring’s precision fit is crucial in maintaining the engine’s operational integrity, especially in environments where exposure to the elements is a concern 12.

Grouping for Enhanced Understanding

When considering the K19, K38, and K50 engines, it is evident that the O-Ring Seal 3897381 is designed to provide a universal fit across these models. This compatibility ensures that maintenance and replacement parts are easily accessible, streamlining the maintenance process for these engines.

For the QSK19 CM850 MCRS engine, while it belongs to a different category, the O-Ring Seal 3897381 still offers the same level of precision and reliability. This ensures that the engine can maintain its operational standards, even in challenging environments 13.

Role of Part 3897381 O-Ring Seal in Engine Systems

The part 3897381 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. It is strategically placed in areas where sealing is required to prevent leaks and ensure optimal performance.

Connection Points

At connection points within the engine, the O-Ring Seal ensures a tight and reliable seal. This is particularly important in joints where different components meet, such as the interface between the engine block and various peripherals. The seal prevents the escape of fluids and gases, maintaining system pressure and efficiency 14.

Raw Water Inlet

In the raw water inlet system, the O-Ring Seal plays a significant role in preventing the ingress of contaminants and the escape of water. This is vital for engines that use raw water for cooling, as any leak can lead to inefficient cooling and potential engine damage 15.

Lower Engine Gasket Kit

Within the lower engine gasket kit, the O-Ring Seal is used to create a barrier between moving parts and stationary components. This helps in maintaining the structural integrity of the engine by preventing oil and other lubricants from leaking out, thus ensuring that all parts are properly lubricated and function smoothly 16.

Pump Systems

In pump systems, whether they handle raw water or seawater, the O-Ring Seal is essential for maintaining the seal around the pump shaft. This prevents water from leaking out and air from being drawn in, which could lead to cavitation and reduced pump efficiency 17.

Seawater Service Kit

When incorporated into a seawater service kit, the O-Ring Seal helps in maintaining the seal in various fittings and connections. This is important for engines that use seawater for cooling, as it ensures that the cooling system operates efficiently without leaks 18.

Conclusion

Overall, the part 3897381 O-Ring Seal is a small yet vital component that contributes to the reliable operation of engine systems by ensuring seals are maintained in critical areas. Its compatibility with various engine models and its role in preventing leaks and maintaining system efficiency make it an indispensable part of commercial truck maintenance 19.

-

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613219, Engine: D6.7 CM2670 D107B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.