This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3912822 O-Ring Seal, manufactured by Cummins, is a component designed to enhance the reliability and efficiency of commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces this O-Ring Seal to meet the demanding requirements of truck maintenance and operation. This part plays a role in ensuring the smooth functioning of various truck systems by providing effective sealing solutions.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, used to create seals between two or more parts. They are widely employed in mechanical systems to prevent leaks of fluids and gases, ensuring the integrity of the system. O-Ring Seals function by deforming under compression when installed in a groove, creating a seal that can withstand pressure and environmental conditions. Their versatility makes them suitable for a range of applications, from simple fluid systems to complex machinery 1.

Purpose of the 3912822 O-Ring Seal in Truck Operations

This Cummins part is specifically designed for use in commercial trucks, where it supports various systems by providing reliable seals. Its application areas include fuel systems, hydraulic systems, and engine components. By ensuring that these systems remain sealed, the O-Ring Seal contributes to the overall efficiency and reliability of truck operations. It helps maintain system pressure, prevent leaks, and protect sensitive components from contaminants 2.

Key Features of the 3912822 O-Ring Seal

This part is engineered with specific design and material characteristics to enhance its performance in demanding truck environments. It is made from high-quality elastomeric materials that offer excellent resistance to oils, fuels, and other chemicals commonly found in truck systems. The seal’s design ensures it can withstand high pressures and temperatures, providing durable and reliable sealing solutions. Additionally, its precise dimensions ensure a proper fit in the designated grooves, maximizing its effectiveness.

Benefits of Using the 3912822 O-Ring Seal

Utilizing this Cummins part in truck operations offers several advantages. It contributes to improved system reliability by ensuring effective seals, which reduces the risk of leaks and system failures. The seal’s durability leads to reduced maintenance needs, as it is designed to withstand the harsh conditions of truck environments. Furthermore, by maintaining system integrity, the O-Ring Seal enhances overall system efficiency, contributing to better truck performance.

Installation and Maintenance Guidelines

Proper installation of this part is crucial for its effectiveness. It should be installed in a clean, undamaged groove to ensure a proper seal. During installation, care should be taken to avoid damaging the seal. Routine maintenance practices include inspecting the seal for signs of wear or damage and replacing it as necessary. Keeping the seal and its groove clean and free of contaminants will also help ensure its longevity and optimal performance.

Troubleshooting Common Issues

Common issues with O-Ring Seals in truck applications include leaks, seal deformation, and failure due to exposure to incompatible fluids or extreme conditions. To diagnose these issues, inspect the seal and its groove for damage, ensure proper installation, and verify compatibility with the system’s fluids and operating conditions. Resolving these issues may involve replacing the seal, cleaning the groove, or addressing system conditions that may be affecting seal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding needs of commercial and industrial applications. Cummins’ commitment to quality and innovation is evident in its wide array of products, including the 3912822 O-Ring Seal, which exemplifies the company’s dedication to enhancing the performance and reliability of commercial vehicles.

Cummins O-Ring Seal 3912822 Compatibility

The Cummins O-Ring Seal part number 3912822 is designed to fit a variety of Cummins engines, ensuring a secure seal in various applications. Here is a detailed breakdown of the engines this part is compatible with:

B5.9 Series Engines

- B5.9 G

- B5.9 GAS PLUS CM556

G5.9 Series Engines

- G5.9

- G5.9 CM558

ISB Series Engines

- ISB CM550

- ISB CM850

ISC and ISL Series Engines

- ISC CM554

- ISL CM554

ISX Series Engines

- ISX CM570

QSB5.9 Series Engines

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM850

QSC8.3 Series Engines

- QSC8.3 CM554

QSL9 Series Engines

- QSL9 CM554

QST30 Series Engines

- QST30 CM552

This O-Ring Seal is engineered to provide a reliable seal in various engine components, ensuring optimal performance and preventing leaks. It is essential to verify the specific application within the engine for proper installation.

Role of Part 3912822 O-Ring Seal in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids and gases are contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

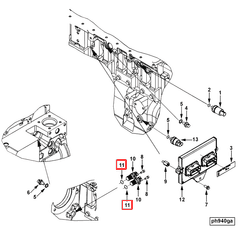

Integration with Engine Components

-

Accessory Drive Support: The O-Ring Seal is used to secure connections within the accessory drive support, ensuring that lubricants and coolants do not escape, which is essential for the longevity and performance of driven accessories.

-

Cylinder Block and Related Assemblies: In the cylinder block, short block, and short block kit, the O-Ring Seal plays a key role in sealing fluid passages and coolant channels. This is vital for maintaining consistent engine temperature and preventing coolant loss.

-

Engine Block and Short Block Variants: Whether it’s the standard engine block, short 6-BT block, short E2 incentive block, or short Euro1 block, the O-Ring Seal is employed to ensure that all fluid connections are tight and secure, which is fundamental for engine reliability.

-

Crankshaft and Bearings: The seal is also critical in the assembly of the crankshaft and its bearings, where it helps to retain lubricants within the bearing surfaces, reducing friction and wear.

-

Front Gear Cover: Within the front gear cover, the O-Ring Seal ensures that gear lubricants remain contained, which is necessary for the smooth operation of the gear train and associated components.

-

Hydraulic Pump and Vacuum/Hydraulic Systems: In hydraulic pump and vacuum/hydraulic systems, the seal is used to maintain system pressure and prevent fluid leakage, which is essential for the actuation of various engine controls and systems.

-

Service Block and Short E1 180 Block: These blocks utilize the O-Ring Seal to ensure that service fluids are properly contained, which is important during maintenance procedures and for the overall serviceability of the engine.

-

Position Sensor and Engine Control Module: Although not directly interfacing with these electronic components, the O-Ring Seal is often found in the fluid pathways that these sensors and modules monitor, ensuring accurate readings and control signals.

Summary of Component Interaction

The O-Ring Seal, part 3912822, is a ubiquitous component across various engine systems, providing a reliable seal for fluid and gas pathways. Its proper installation and maintenance are key to the efficient operation and durability of the engine and its subsystems.

Conclusion

The 3912822 O-Ring Seal by Cummins is a critical component in the maintenance and operation of commercial trucks. Its design and material characteristics ensure it can withstand the demanding conditions of truck environments, providing durable and reliable sealing solutions. Proper installation and maintenance of this part are essential for the efficient operation and durability of the engine and its subsystems. By understanding the role and benefits of this Cummins part, truck operators and maintenance professionals can ensure the optimal performance and reliability of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.