3915800

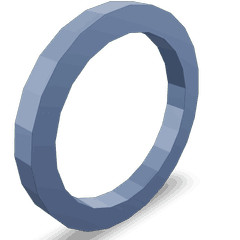

Rectangular Ring Seal

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3915800 Rectangular Ring Seal, manufactured by Cummins, is a critical component in the commercial truck industry. This seal is designed to ensure the efficient operation of a truck’s engine or transmission system by preventing leaks and maintaining system integrity.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a gasket used in mechanical systems to prevent leaks between mating surfaces. It creates a tight seal that can withstand pressure and temperature variations, commonly used in applications requiring robust and reliable sealing 1.

Purpose of the 3915800 Rectangular Ring Seal

The 3915800 Rectangular Ring Seal is essential for the operation of a truck’s engine or transmission system. It ensures that fluids remain contained within their designated pathways, preventing leaks that could lead to system failure or reduced efficiency. By maintaining a secure seal, this component contributes to the overall reliability and performance of the truck 2.

Key Features

The 3915800 Rectangular Ring Seal features several attributes that enhance its performance:

- Composed of durable materials to withstand high pressures and temperatures.

- Rectangular cross-section provides a larger sealing surface area compared to traditional O-rings, offering improved sealing efficiency.

- Engineered to resist wear and tear, ensuring long-lasting performance.

Benefits

The advantages of the 3915800 Rectangular Ring Seal include:

- Enhanced sealing efficiency, helping maintain system pressure and prevent leaks.

- Durability and resistance to wear and tear, contributing to a longer service life.

- Design allows it to accommodate minor misalignments between mating surfaces, further enhancing reliability.

Installation Process

Proper installation of the 3915800 Rectangular Ring Seal is crucial for ensuring a secure fit and optimal performance. The process involves:

- Cleaning the mating surfaces to remove any debris or old sealant.

- Lubricating the seal with a compatible lubricant to facilitate installation and reduce the risk of damage.

- Carefully placing the seal into the groove, ensuring it is seated correctly without twists or folds.

- Testing the system for leaks after installation to confirm the seal’s integrity.

Troubleshooting Common Issues

Common problems associated with Rectangular Ring Seals include leaks or failure due to wear, damage, or improper installation. To diagnose these issues:

- Inspect the seal for signs of wear, such as cracks or deformation.

- Check the mating surfaces for damage or misalignment that could affect the seal’s performance.

- If a leak is detected, the seal may need to be replaced, and the mating surfaces should be inspected and cleaned as necessary.

Maintenance Tips

Regular maintenance practices can help prolong the lifespan of the 3915800 Rectangular Ring Seal. Inspect the seal and mating surfaces during routine maintenance checks for signs of wear or damage. Clean the surfaces to remove any contaminants that could affect the seal’s performance. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help ensure the seal continues to function effectively.

Replacement Guidelines

Determining when to replace the 3915800 Rectangular Ring Seal involves monitoring for signs of wear, damage, or performance decline. If the seal shows signs of cracking, deformation, or if leaks are detected, it should be replaced. Additionally, if the seal has reached the end of its service life as indicated by the manufacturer’s guidelines, replacement is recommended to maintain system integrity and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 3.

Cummins Rectangular Ring Seal 3915800 Compatibility

The Cummins Rectangular Ring Seal part number 3915800 is designed to fit a variety of Cummins engines, ensuring a secure seal that is essential for maintaining engine performance and efficiency. Below is a detailed description of the engines that this seal is compatible with:

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B3.9 G

- B4.5

- G5.9

- G5.9 CM558

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSC8.3 CM554

- QSL9 CM554

Grouping of Compatible Engines

-

QSB Series:

- QSB3.9 30 CM550

- QSB5.9 30 CM550

-

QSC and QSL Series:

- QSC8.3 CM554

- QSL9 CM554

-

B and G Series:

- B3.9 G

- B4.5

- G5.9

- G5.9 CM558

-

Other Series:

- 4B3.9

- 6B5.9

- 6C8.3

This seal is engineered to fit seamlessly within these engine models, providing a reliable barrier against leaks and ensuring that the engine operates at optimal efficiency.

Role of Part 3915800 Rectangular Ring Seal in Engine Systems

The 3915800 Rectangular Ring Seal is integral to the efficient operation of various engine components. It ensures a secure and leak-proof seal in systems where fluid dynamics and mechanical integrity are paramount.

Coupling and Fuel Pump

In the coupling and fuel pump systems, the 3915800 Rectangular Ring Seal prevents fuel leakage, maintaining the system’s efficiency and safety. Its precise fit ensures that the fuel pump operates under optimal conditions, delivering consistent fuel pressure to the engine.

Cover and Front Gear

When installed in the cover and front gear assemblies, this seal plays a significant role in containing lubricants. Proper lubrication is essential for the smooth operation of the front gear, reducing wear and tear and enhancing the longevity of the engine components.

Signal Generating Device and Drive Systems

In signal generating devices and drive systems, such as the tachometer drive and mechanical tachometer drive, the seal ensures that no fluids interfere with the accurate generation and transmission of signals. This is vital for the precise monitoring of engine performance.

Front Gear Train Accessory Drive

For the front gear train accessory drive, the 3915800 Rectangular Ring Seal helps in maintaining the integrity of the accessory drive system. It ensures that the drive components remain well-lubricated and free from contaminants, which is essential for their reliable operation.

Instrument and Engine Components

In instruments connected to the engine, such as the mechanical tachometer, the seal ensures that the instrument housing remains free from fluid ingress. This protects the sensitive components within the instrument, ensuring accurate readings and reliable performance.

Lower Engine Gasket Kit and Set

In the lower engine gasket kit and set, the seal is used to ensure that the lower engine components are well-sealed. This prevents oil leaks and maintains the engine’s overall efficiency and performance.

Mechanical Tachometer Drive and Kit

For the mechanical tachometer drive and kit, the seal ensures that the drive components are protected from fluid contamination. This is essential for the accurate transmission of engine RPM data to the tachometer.

Overhaul and Rebuild Kits

In overhaul and rebuild kits, the 3915800 Rectangular Ring Seal is often included to ensure that during engine maintenance or rebuild, the sealing integrity of various components is maintained. This is vital for the successful restoration of the engine to its optimal working condition.

Conclusion

The 3915800 Rectangular Ring Seal by Cummins is a vital component in ensuring the efficient and reliable operation of commercial truck engines. Its robust design, durability, and compatibility with various Cummins engines make it an essential part for maintaining system integrity and performance. Proper installation, regular maintenance, and timely replacement are key to maximizing the benefits of this seal.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.