3930324

Injector Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

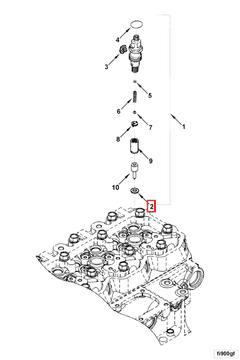

The Cummins 3930324 Injector Seal is a critical component in the fuel injection systems of commercial trucks. It ensures the integrity of the fuel delivery system by preventing leaks and maintaining proper pressure within the system. This part plays a significant role in the overall performance and efficiency of the truck’s engine.

Purpose and Function

The Cummins Injector Seal facilitates the precise delivery of fuel to the engine’s combustion chambers. By creating a tight seal around the injector, it prevents fuel from leaking into areas where it could cause damage or reduce efficiency. This seal ensures that the fuel is delivered under the correct pressure, which is vital for the engine’s combustion process and overall performance 1.

Key Features

This Cummins part is crafted from materials that offer high resistance to wear and the corrosive effects of fuel. Its design includes features that allow it to withstand the high pressures and temperatures present in the fuel injection system. These characteristics contribute to the seal’s durability and effectiveness in demanding environments 2.

Benefits

Utilizing the Cummins Injector Seal can lead to several advantages for truck operators. These include improved engine efficiency due to consistent fuel delivery, reduced maintenance costs as a result of the seal’s longevity, and enhanced reliability of the fuel injection system. The seal’s design also contributes to lower emissions by ensuring that fuel is not wasted through leaks 3.

Installation and Maintenance

Proper installation of the Cummins Injector Seal is crucial for its performance. It should be fitted according to the manufacturer’s specifications to ensure a secure and effective seal. Regular maintenance checks are recommended to ensure the seal remains in good condition. This may include inspecting for signs of wear or damage and replacing the seal as necessary to maintain the integrity of the fuel injection system.

Troubleshooting Common Issues

Injector seals may encounter issues such as leaks or failure over time. Common diagnostic steps include checking for fuel leaks around the injector, assessing the seal for physical damage, and ensuring that the injector is properly seated. If a problem is detected, the seal may need to be replaced to restore the system’s functionality.

Manufacturer Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of diesel engines and related components. With a history of innovation and quality, Cummins provides a variety of products designed to enhance the performance and reliability of commercial vehicles. The company’s reputation is built on its commitment to excellence and customer satisfaction.

Compatibility

The Cummins Injector Seal part number 3930324 is designed to fit seamlessly with the following engines:

- 4B3.9

This seal is crucial for maintaining the integrity of the fuel injection system by preventing leaks at the injector interface. It ensures that the engine operates efficiently and reliably by keeping the combustion environment sealed. The seal is engineered to withstand the high pressures and temperatures typical of diesel engines, providing a durable and long-lasting solution.

Role in Engine Systems

The injector seal, identified by part number 3930324, is an essential component in maintaining the integrity and efficiency of fuel injection systems within internal combustion engines. Its primary function is to create a secure and leak-free connection between the injector and the engine block or cylinder head. This seal is integral to the performance and reliability of several key engine components and systems.

Integration with Injector Systems

In fuel injection systems, the injector seal ensures that fuel is delivered precisely and efficiently to the combustion chamber. By preventing fuel leaks, the seal helps maintain consistent fuel pressure and delivery, which is vital for optimal engine performance. This is particularly important in high-performance engines where precise fuel metering is necessary to achieve maximum power output and efficiency.

Role in Overhaul Kits

When performing a pistonless overhaul, which involves replacing components above the pistons such as gaskets, seals, and injectors, the injector seal plays a significant role. A reliable seal is necessary to ensure that the overhauled injector functions correctly without any fuel leaks, thereby contributing to the overall success of the overhaul process.

Contribution to Rebuild Kits

Rebuild kits, which typically contain a comprehensive set of parts needed to rebuild an engine, also include injector seals. These seals are vital for ensuring that the rebuilt engine’s fuel injection system functions correctly. By providing a tight seal, they help maintain fuel pressure and prevent leaks, which are essential for the engine’s performance and longevity.

Function in Upper Engine Gasket Kits and Sets

Upper engine gasket kits and sets are designed to replace gaskets and seals in the upper portion of the engine, including those around the injectors. The injector seal is a key component in these kits, ensuring that the gasket set effectively seals the injector to the engine block or cylinder head. This is important for preventing fuel leaks and maintaining the engine’s overall efficiency and performance.

Enhancing Engine Performance

The injector seal, as part of various engine kits and components, contributes to enhancing engine performance. By ensuring a secure and leak-free connection, it helps maintain consistent fuel delivery, which is essential for achieving optimal combustion and power output. This is particularly important in performance engines where every component must work seamlessly to deliver maximum efficiency and power.

Conclusion

In summary, the Cummins Injector Seal (part 3930324) is a vital component in various engine systems and kits, playing a key role in maintaining fuel integrity, preventing leaks, and ensuring optimal engine performance. Its integration into injector systems, overhaul kits, rebuild kits, and upper engine gasket sets underscores its importance in the overall functionality and reliability of internal combustion engines.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.