This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3944900 O-Ring Seal is a critical component in maintaining the integrity of seals within commercial truck systems. It ensures operational efficiency and reliability of truck engines and related systems by preventing leaks and maintaining correct pressure conditions.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a gasket with a circular cross-section, designed to create a seal between two or more parts by being compressed within a groove. This forms a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems for their simplicity, effectiveness, and versatility 1.

Purpose of the 3944900 O-Ring Seal in Truck Operations

This Cummins part ensures sealing integrity in various systems such as fuel lines, hydraulic systems, and engine components. It is applied in areas where fluid or gas containment is necessary to maintain system performance and prevent leaks that could lead to inefficiencies or operational failures.

Key Features of the 3944900 O-Ring Seal

The design and material characteristics of this part contribute to its effectiveness and longevity. Crafted from durable materials, it exhibits resistance to environmental factors including temperature variations, chemical exposure, and mechanical stress. Its compatibility with truck systems ensures it can withstand the demanding conditions of commercial truck operations.

Benefits of Using the 3944900 O-Ring Seal

Utilizing this part offers several advantages. It contributes to improved system efficiency by ensuring tight seals, which helps in maintaining the correct pressure and flow rates within systems. Additionally, it reduces maintenance needs due to its durability and resistance to wear and environmental factors. The seal also enhances the reliability of truck operations by minimizing the risk of leaks and system failures.

Installation and Maintenance Guidelines

Proper installation of this part is vital for its effectiveness. It should be installed in clean, undamaged grooves to ensure a proper seal. Regular maintenance practices, such as inspecting for wear and damage, and replacing the seal as needed, are recommended to ensure longevity and performance. Careful handling during installation and operation can prevent damage and extend the seal’s service life.

Troubleshooting Common Issues

Typical problems associated with O-Ring Seals in truck applications include leaks, which can be caused by wear, damage, or improper installation. Diagnostic methods involve inspecting the seal and its groove for signs of wear or damage. Solutions may include cleaning the groove, replacing the seal, or addressing any underlying issues that may have caused the seal to fail.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and industrial markets. The company is known for its commitment to providing reliable and efficient power solutions, backed by a strong reputation in the industry.

Cummins O-Ring Seal Part 3944900 Compatibility

The Cummins O-Ring Seal part number 3944900 is designed to fit seamlessly within several of Cummins’ engine models. This part is a critical component that ensures the integrity of the engine’s sealing system, preventing leaks and maintaining operational efficiency.

ISB CM550 and ISV (Nissan)

The ISB CM550 and ISV (Nissan) engines both benefit from the precision fit of the 3944900 O-Ring Seal. This part is engineered to provide a reliable seal in various engine components, ensuring that the engine operates smoothly and efficiently. Its placement in these engines is crucial for maintaining the necessary pressure and preventing any fluid leaks that could compromise engine performance.

QSB5.9 44 CM550

Similarly, the QSB5.9 44 CM550 engine incorporates the 3944900 O-Ring Seal in several key areas. This seal is essential for maintaining the engine’s internal pressures and preventing leaks, which is vital for the engine’s longevity and performance. Its compatibility with the QSB5.9 44 CM550 ensures that the engine can operate under various conditions without the risk of seal failure.

By ensuring that the 3944900 O-Ring Seal is correctly installed in these engines, users can maintain the engine’s efficiency and reliability, preventing potential issues that could arise from seal degradation or failure.

Role of Part 3944900 O-Ring Seal in Engine Systems

This part is an essential component in ensuring the integrity and efficiency of various engine systems. Its application across different components highlights its versatility and importance in maintaining optimal engine performance.

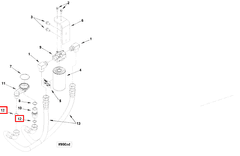

Front Cover

In the front cover of an engine, the O-Ring Seal plays a significant role in preventing oil leaks. It ensures that the oil remains contained within the engine, thereby maintaining lubrication and reducing the risk of contamination. This seal is positioned between the front cover and the engine block, creating a tight barrier that withstands the pressures and temperatures within the engine compartment.

Front Sprocket Cover

For the front sprocket cover, the O-Ring Seal is vital in sealing the interface between the cover and the engine. This prevents debris and contaminants from entering the engine, which could otherwise lead to wear and damage. The seal also helps in retaining lubricants, ensuring that the sprocket and chain mechanism operates smoothly and efficiently.

Full Flow Oil Filter

In the context of the full flow oil filter, the O-Ring Seal is used to create a secure connection between the filter housing and the engine block. This seal is responsible for maintaining the pressure integrity of the oil filtration system, ensuring that oil flows through the filter without any bypass, thus maximizing the filtration efficiency and prolonging the life of the engine components.

Thermostat

The thermostat housing often incorporates an O-Ring Seal to ensure a leak-free connection to the engine block. This seal is essential for maintaining the coolant system’s integrity, preventing leaks that could lead to overheating or engine damage. It ensures that the coolant circulates effectively, helping to regulate the engine temperature and enhance overall performance.

Conclusion

The Cummins 3944900 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, maintaining system pressure, and ensuring the efficiency and reliability of engine systems cannot be overstated. Proper installation, regular maintenance, and timely replacement of this part are essential practices for ensuring the longevity and performance of truck engines.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.