This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3973905 Orange Ring Seal is a specialized component designed for use in commercial trucks. It plays a role in maintaining the integrity of the engine or transmission system by providing a reliable seal that prevents fluid leaks and ensures efficient operation. Understanding its purpose and significance is key to maintaining the performance and longevity of commercial vehicles.

Basic Concepts of Orange Ring Seals

An Orange Ring Seal is a type of mechanical seal that utilizes an elastomeric ring to create a seal between two surfaces. It functions by compressing the ring against a sealing surface, which creates a barrier that prevents the leakage of fluids. These seals are commonly used in various mechanical systems where fluid containment is necessary, such as in engines, transmissions, and hydraulic systems 1.

Purpose of the Cummins 3973905 Orange Ring Seal

This Cummins part ensures a secure seal within the engine or transmission system. It is designed to withstand high pressures and temperatures, which are common in these environments. By maintaining a tight seal, it helps to prevent fluid leaks that could lead to system failure or reduced efficiency 2.

Key Features

The primary characteristics of the 3973905 Orange Ring Seal include its material composition, which typically consists of durable elastomers that can withstand the harsh conditions within a truck’s engine or transmission. Its design is engineered to provide a robust seal, and it may feature unique attributes such as reinforced edges or specific geometries that enhance its performance and longevity.

Benefits of Using the 3973905 Orange Ring Seal

Incorporating this part into truck maintenance and operation offers several advantages. These include increased durability under demanding conditions, improved efficiency by preventing fluid leaks, and enhanced reliability, which contributes to the overall performance and lifespan of the vehicle.

Installation Process

Proper installation of the 3973905 Orange Ring Seal is crucial for ensuring optimal performance and longevity. The process involves cleaning the sealing surfaces, lubricating the seal, and carefully placing it into the designated groove. It is important to follow manufacturer guidelines to avoid damage to the seal or the surrounding components.

Troubleshooting Common Issues

Frequent problems associated with Orange Ring Seals can include leaks, wear, or failure to seat properly. Potential causes may be improper installation, contamination, or excessive wear. Recommended solutions include re-evaluating the installation process, ensuring cleanliness of the sealing surfaces, and replacing the seal if it shows signs of wear or damage.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 3973905 Orange Ring Seal. This includes routine inspections for signs of wear or damage, ensuring that sealing surfaces remain clean and free of contaminants, and following replacement guidelines based on the manufacturer’s recommendations or operational conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines, powertrains, and related components that are designed to meet the demanding requirements of commercial vehicles 3.

Role of Part 3973905 Orange Ring Seal in Engine Systems

This part is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between moving and stationary parts, preventing leaks and ensuring optimal performance.

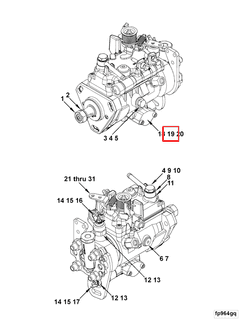

In the Fuel Injection Pump, the Orange Ring Seal is positioned at critical junctures where high-pressure fuel lines connect to the pump body. This seal ensures that fuel is delivered under precise pressure without any leakage, which is vital for the consistent operation of the injection system.

Within the Fuel Pump assembly, the Orange Ring Seal plays a similar role. It is used at connection points to maintain the integrity of the fuel flow from the tank to the engine. This seal helps in sustaining the required fuel pressure, which is necessary for efficient combustion.

For the general Pump components, whether they are part of the fuel system or other fluid systems within the engine, the Orange Ring Seal ensures that the fluid dynamics are maintained without any loss. This is particularly important in systems where precise fluid measurement and delivery are required.

In the broader context of the Fuel System, the Orange Ring Seal is employed at various connection points to ensure that the fuel path remains sealed. This is important for maintaining fuel pressure and preventing any fuel from escaping, which could lead to inefficiencies or safety hazards.

Lastly, in the Fuel Injection system, the Orange Ring Seal is used to secure connections between the injectors and the fuel rail. This ensures that fuel is delivered to each cylinder under the correct pressure, contributing to the overall performance and efficiency of the engine.

Conclusion

The Cummins 3973905 Orange Ring Seal is a critical component for maintaining the performance and reliability of commercial truck engines. Its precise fit, robust design, and adaptability across various engine models make it an invaluable part of engine maintenance and operation.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.