This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

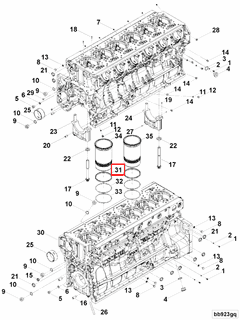

The 4006178 Liner Seal Ring, manufactured by Cummins, is a critical component in the operation of commercial truck engines. Cummins, a renowned name in engine manufacturing, produces this part to ensure the efficient and reliable performance of truck engines.

Basic Concepts of Liner Seal Rings

A Liner Seal Ring is a component used in engines to create a seal between the cylinder liner and the engine block. Its primary function is to prevent coolant and oil from leaking into the combustion chamber, which could lead to engine inefficiency and potential damage. By maintaining proper sealing, the Liner Seal Ring contributes to the overall performance and longevity of the engine 2.

Purpose of the 4006178 Liner Seal Ring

The 4006178 Liner Seal Ring is specifically designed to enhance the operation of truck engines. It plays a role in sealing the cylinder liner to the engine block, which helps in maintaining the integrity of the coolant and oil systems. This seal is vital for engine efficiency, as it ensures that these fluids do not interfere with the combustion process. Additionally, proper sealing contributes to the durability of the engine by preventing wear and potential damage caused by fluid leaks 3.

Key Features

The 4006178 Liner Seal Ring is characterized by several key features that enhance its performance. It is made from high-quality materials that are resistant to wear and capable of withstanding high temperatures and pressures. The design of the seal ring is optimized to provide a tight and reliable seal, ensuring that coolant and oil are effectively contained. Additionally, the seal ring may feature unique attributes such as anti-extrusion elements to further enhance its durability and performance 4.

Benefits

Using the 4006178 Liner Seal Ring offers several benefits. It contributes to improved engine performance by ensuring that the combustion process is not compromised by fluid leaks. The seal ring’s durable construction and reliable sealing capabilities lead to increased engine longevity. Moreover, by preventing leaks and maintaining engine efficiency, the use of this seal ring can result in potential cost savings over time, as it reduces the need for frequent repairs and maintenance 1.

Installation Process

Installing the 4006178 Liner Seal Ring requires careful attention to detail to ensure optimal performance. The process involves cleaning the sealing surfaces to remove any debris or old sealant. The seal ring should be lubricated before installation to facilitate proper seating. Using the appropriate tools, the seal ring is then placed into the groove between the cylinder liner and the engine block. It is important to ensure that the seal ring is evenly seated and not twisted or misaligned. Following installation, the engine should be inspected for proper sealing before operation 2.

Troubleshooting Common Issues

Common issues with Liner Seal Rings may include leaks or signs of wear. If a leak is detected, it is important to inspect the seal ring for damage or improper seating. Wear may be indicated by irregularities in the seal ring’s surface or a reduction in its effectiveness. Troubleshooting steps may involve cleaning the sealing surfaces, replacing the seal ring if necessary, and ensuring that the installation process was correctly followed. Regular inspections can help identify potential issues before they lead to significant problems 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 4006178 Liner Seal Ring, regular maintenance is recommended. This includes inspecting the seal ring during routine engine maintenance checks for signs of wear or damage. Cleaning the sealing surfaces to remove any contaminants that could affect the seal’s performance is also important. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain engine efficiency and prevent unexpected failures 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the engine manufacturing industry. The company is known for its expertise, commitment to quality, and innovation in developing products that meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to excellence is reflected in its wide range of engine components, including the 4006178 Liner Seal Ring, designed to enhance the performance and reliability of engines in various applications.

Cummins Liner Seal Ring Part 4006178 in Engine Applications

The Cummins Liner Seal Ring part number 4006178 is a critical component in ensuring the integrity and efficiency of the engine’s combustion process. This seal ring is designed to fit seamlessly within the engine architecture, providing a tight seal between the cylinder liner and the piston. This seal is essential for maintaining optimal compression and preventing oil leakage, which is crucial for the longevity and performance of the engine.

Engine Compatibility

The Liner Seal Ring part 4006178 is compatible with several Cummins engine models, including but not limited to:

- QSK78

- CM500

These engines are known for their robust design and are widely used in various applications, from industrial machinery to marine and power generation systems. The seal ring’s design ensures it can withstand the high pressures and temperatures typical of these engines, providing a reliable barrier against oil and combustion gases.

Installation and Functionality

When installed, the Liner Seal Ring part 4006178 fits snugly within the cylinder liner, creating a barrier that prevents oil from entering the combustion chamber. This is crucial for maintaining engine efficiency and preventing oil contamination of the combustion process. The seal ring also helps in maintaining the proper compression levels, which is vital for the engine’s performance and fuel efficiency.

Importance in Engine Performance

The proper functioning of the Liner Seal Ring part 4006178 is paramount for the overall health of the engine. A compromised seal can lead to oil consumption issues, reduced engine efficiency, and potential engine damage over time. Regular inspection and timely replacement of this component are recommended to ensure the engine operates at peak performance.

Application Across Engine Models

The compatibility of the Liner Seal Ring part 4006178 across various Cummins engine models underscores its versatility and importance in the engine’s design. Whether in the QSK78 or CM500 engines, this seal ring plays a pivotal role in maintaining the engine’s operational integrity and efficiency.

Role of Part 4006178 Liner Seal Ring in Engine Systems

The Liner Seal Ring, identified by part number 4006178, is an essential component in ensuring the efficient and reliable operation of various engine systems. Its primary function is to provide a secure seal between the liner and the cylinder block, preventing any leakage of combustion gases and lubricants.

Integration with Cylinder Block and Liner

When installed, the Liner Seal Ring fits snugly between the cylinder block and the liner. This arrangement is vital for maintaining the integrity of the combustion chamber. The seal ring ensures that the high-pressure gases produced during combustion remain contained within the cylinder, thereby maximizing engine efficiency and power output.

Interaction with Liner Kit and Cylinder Liner

In conjunction with the Liner Kit, the Liner Seal Ring plays a significant role in the overall durability and performance of the engine. The Liner Kit typically includes the cylinder liner and other necessary components to facilitate the installation and maintenance of the liner. The seal ring, when properly installed, enhances the liner’s ability to withstand thermal and mechanical stresses, contributing to the longevity of the engine.

Contribution to Cam Follower Assembly

The Liner Seal Ring also indirectly supports the Cam Follower Assembly by maintaining a stable and sealed environment within the cylinder. This stability is essential for the precise operation of the cam follower, which relies on consistent pressure and lubrication conditions to function correctly.

Role in PDC (Piston, Connecting Rod, and Crankshaft) System

In the PDC system, the Liner Seal Ring ensures that the piston’s movement within the cylinder is smooth and free from interference by unwanted gases or lubricants. This seal is particularly important in high-performance engines where even minor leaks can significantly impact engine efficiency and reliability.

Summary of Component Interactions

- Cylinder Block: The seal ring ensures a tight fit between the block and the liner, preventing gas and lubricant leakage.

- Cylinder Liner: Works in tandem with the liner to enhance durability and performance under stress.

- Liner Kit: Facilitates the installation and maintenance of the liner, with the seal ring playing a key role in the kit’s effectiveness.

- Cam Follower Assembly: Indirect support by maintaining a stable cylinder environment.

- PDC System: Ensures smooth piston movement and maintains engine efficiency.

Conclusion

The 4006178 Liner Seal Ring is a vital component in the operation of Cummins engines, ensuring the integrity and efficiency of the combustion process. Its role in sealing the cylinder liner to the engine block is crucial for maintaining engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.