4007147

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007147 O-Ring Seal is a component designed to ensure the integrity of various systems in commercial trucks. Its purpose is to provide a reliable seal in applications where fluid or gas containment is required. The significance of this O-Ring Seal lies in its ability to prevent leaks, which can lead to system failures and increased maintenance costs 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by deforming slightly when compressed between flanges or in a groove, creating a barrier that prevents the passage of fluids or gases. This function is vital in maintaining the efficiency and safety of mechanical systems 2.

Purpose of the 4007147 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing of various systems where fluid or gas containment is necessary. It is commonly used in fuel systems, hydraulic systems, and other critical areas where leaks can cause significant issues. Its application helps maintain system pressure and efficiency, contributing to the overall performance of the truck 3.

Key Features of the 4007147 O-Ring Seal

This part is characterized by several key features that enhance its performance. These include its material composition, which is typically made from durable elastomers to withstand high pressures and temperatures. The design of the seal ensures it can conform to irregular surfaces, providing a consistent seal. Additionally, its durability is a significant factor, allowing it to maintain its sealing properties over extended periods.

Benefits of Using the 4007147 O-Ring Seal

Using this Cummins part offers several benefits. It provides improved sealing efficiency, reducing the risk of leaks in demanding truck environments. The seal’s longevity ensures that it can withstand the rigors of commercial truck operation, and its reliability contributes to the overall dependability of the truck’s systems.

Installation Guidelines

Proper installation of this Cummins part is crucial for its optimal performance. The installation process involves ensuring the groove where the seal will reside is clean and free of debris. The seal should be lubricated before installation to facilitate its seating. Care should be taken to avoid damaging the seal during installation, as this can compromise its sealing ability.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, which can be caused by improper installation, damage to the seal, or degradation of the seal material. Addressing these issues involves inspecting the seal and its seating area for damage, ensuring proper installation techniques are used, and replacing the seal if necessary.

Maintenance Tips

Regular maintenance practices can prolong the life of the 4007147 and ensure continued reliable performance. This includes periodic inspection of the seal for signs of wear or damage, cleaning the seating area to prevent contamination, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product offerings include a wide range of engines, components, and technologies designed to meet the needs of its customers in various industries.

Cummins Engine O-Ring Seal 4007147 Compatibility

This Cummins part, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engine models. This seal is crucial for maintaining the integrity of various systems within the engine by preventing leaks and ensuring that components operate efficiently.

QSK45 CM500, QSK60 CM500, and QSK78 CM500

This part is compatible with the QSK45 CM500, QSK60 CM500, and QSK78 CM500 engines. These engines are part of the QSK series, known for their robust design and reliability in demanding applications. The seal ensures that the engine’s internal systems remain sealed, which is vital for maintaining performance and longevity.

QSK95 CM2350 K111 and QSK95 CM2350 K113

This part also fits the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are part of the QSK95 series, which is designed for high-power applications. The seal’s precision fit is essential for these engines, as it helps to maintain the high-pressure environments within the engine, ensuring optimal performance and efficiency.

QSV91-G4 CM558/CM700 V102

This part is also suitable for the QSV91-G4 CM558/CM700 V102 engine. This engine is part of the QSV series, which is known for its versatility and adaptability in various industrial applications. The seal’s role in this engine is to provide a reliable barrier against leaks, ensuring that the engine operates smoothly and efficiently under different conditions.

Each of these engines benefits from the 4007147, which is engineered to meet the specific requirements of Cummins’ high-performance engines. This seal is a critical component in maintaining the engine’s operational integrity and ensuring that it performs reliably over time.

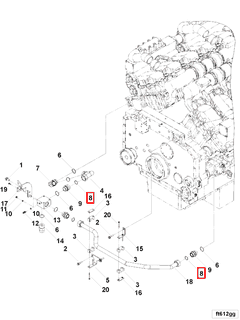

Role of Part 4007147 O-Ring Seal in Engine Systems

The O-Ring Seal, identified as part 4007147, is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that each system operates smoothly and without leaks.

Accessories

In accessory systems, the O-Ring Seal is employed to create a tight seal between moving and stationary parts. This prevents fluid or gas leakage, which is essential for the reliable operation of accessories such as turbochargers and alternators.

Air Starting System

Within the air starting system, the O-Ring Seal is used in conjunction with fittings and unions to ensure that compressed air is delivered efficiently to the engine cylinders. This seal prevents air loss, which is vital for the system’s effectiveness in starting the engine.

Check Valve

The check valve relies on the O-Ring Seal to maintain unidirectional flow. By sealing the valve’s components, it ensures that fluid or air flows in the intended direction, preventing backflow which could compromise system performance.

Drain and Remote Oil Systems

In drain and remote oil systems, the O-Ring Seal is critical for sealing connections in the plumbing. This prevents oil leaks, which are not only messy but can also lead to a loss of lubrication, affecting engine performance and longevity.

Filter and Fuel Systems

For filters and fuel systems, the O-Ring Seal is used in fuel inlets, fuel filters, and top-level assembly heads. It ensures that fuel is delivered cleanly and without contamination, which is essential for combustion efficiency and engine reliability.

Fuel Plumbing and Gasket Kit

In fuel plumbing and within gasket kits, the O-Ring Seal plays a role in creating a barrier that prevents fuel leakage. This is important for safety and for maintaining the correct fuel pressure within the system.

Hose Kit and Male Unions

The O-Ring Seal is also found in hose kits and male unions, where it ensures that connections remain secure under pressure. This is particularly important in dynamic environments where vibrations and movements could otherwise cause seals to fail.

Primer and Engine Lubricating Systems

In primer systems and engine lubricating systems, the O-Ring Seal is used to maintain the integrity of the priming process and to ensure that lubricants are delivered where needed without leakage. This is fundamental for engine start-up and ongoing operation.

Pump and Water Systems

Finally, in pump and water systems, the O-Ring Seal is utilized to prevent leaks in the plumbing and connections. This is essential for maintaining the correct fluid levels and pressures, which are critical for cooling and lubrication within the engine.

Conclusion

The Cummins 4007147 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks and ensuring system integrity cannot be overstated. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are key to maximizing the performance and longevity of this essential part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.