4010577

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4010577 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems in commercial trucks. It prevents leaks and maintains system pressure, enhancing the efficiency and reliability of truck operations 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a circular gasket designed to create a seal between two or more parts by deforming slightly when compressed, thereby filling the gap between mating surfaces to prevent fluid or gas leakage. O-Ring Seals are widely utilized in various mechanical systems for their simplicity, effectiveness, and versatility 2.

Purpose of the 4010577 O-Ring Seal

This Cummins part is specifically engineered to fit within the fluid systems of commercial trucks. It maintains seals at connection points, ensuring that fluids such as coolant, oil, or fuel do not escape. Its precise location within the truck’s systems is essential for the proper functioning of these fluids, which are vital for engine operation and overall vehicle performance.

Key Features

The 4010577 is constructed from materials that offer durability and resistance to a range of operating conditions. Its design specifications are tailored to fit precisely within the truck’s fluid systems, ensuring a tight seal. Unique characteristics of this O-Ring Seal may include specific durometer ratings for optimal elasticity and resistance to compression set, enhancing its performance over time.

Benefits

This part provides several benefits, including improved sealing efficiency, which helps maintain system pressure and prevent leaks. Its durability ensures long-term performance, even under demanding conditions. Additionally, its resistance to various operating conditions, such as temperature fluctuations and exposure to chemicals, contributes to its reliability and longevity.

Installation and Maintenance

Proper installation of the 4010577 is crucial for its effectiveness. Best practices include ensuring the mating surfaces are clean and free of debris before installation, using the correct amount of lubrication to facilitate seating, and avoiding over-tightening, which can damage the seal. Regular maintenance checks can help identify wear or damage early, ensuring the seal continues to perform optimally.

Troubleshooting Common Issues

Common problems with O-Ring Seals, such as leaks or failures, can often be traced back to installation issues or environmental factors. Troubleshooting steps may include inspecting the seal for signs of wear or damage, checking the condition of the mating surfaces, and ensuring that the system is operating within the specified parameters for temperature and pressure.

Manufacturer: Cummins

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. Known for its commitment to quality and innovation, Cummins has a history of producing reliable and high-performance components. The company’s dedication to advancing technology and meeting the needs of its customers underscores the quality and reliability of its products, including the 4010577 O-Ring Seal.

Compatibility

This Cummins part is designed to fit seamlessly within a variety of Cummins engine models, ensuring optimal sealing performance and reliability. It is integral to maintaining the integrity of the engine’s systems by preventing leaks and maintaining pressure.

QSK19 CM500, QSK45 CM500, and QSK60 CM500

The O-Ring Seal is compatible with the QSK19 CM500, QSK45 CM500, and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and efficiency. The seal fits into various components within these engines, ensuring that critical areas such as fuel lines, hydraulic systems, and other fluid pathways remain leak-free.

QSK60G

The QSK60G engine also benefits from the O-Ring Seal. This engine, like its counterparts, relies on precise sealing to maintain operational efficiency and longevity. The part is engineered to fit snugly in the designated areas, providing a dependable barrier against leaks.

QSK78 CM500

Similarly, the QSK78 CM500 engine incorporates the O-Ring Seal. This engine, part of the CM500 series, is designed for heavy-duty applications, and the seal plays a crucial role in maintaining the engine’s performance by ensuring that all critical seals are intact and functioning correctly.

Role in Engine Systems

The O-Ring Seal, identified by part number 4010577, is integral to the functionality and efficiency of various engine components. Its application spans across multiple systems, ensuring optimal performance and reliability.

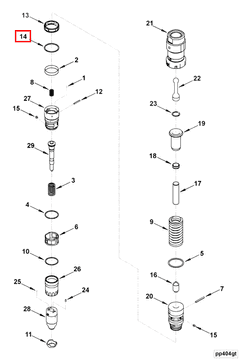

Fuel System Integration

In the fuel system, the O-Ring Seal is employed within the fuel manifold and injector plumbing. It creates a secure seal between the injector and the fuel manifold, preventing fuel leaks and ensuring consistent fuel delivery to the combustion chamber. This seal is also vital in the injector kit, where it maintains the integrity of the fuel supply line connections.

Combustion Chamber Sealing

The O-Ring Seal plays a significant role in the cylinder head and cylinder head gasket kit. It is used to seal the connections between the cylinder head and the engine block, preventing coolant and oil leaks. Additionally, in the head quadrant gasket kit and quadrant cylinder hardware gasket set, the O-Ring Seal ensures that the quadrant components are securely sealed, contributing to the overall integrity of the upper engine assembly.

Injector and Plumbing Systems

Within the injector and injector plumbing systems, the O-Ring Seal is crucial for maintaining the pressure integrity of the fuel lines. It ensures that the fuel injectors receive a consistent fuel supply without any leaks, which is essential for precise fuel injection and engine performance.

Gasket Kits and Sets

The O-Ring Seal is a common component in various gasket kits, including the head gasket set, oversize gasket kit, and upper engine gasket kit. It provides additional sealing where standard gasket materials may not suffice, enhancing the durability and reliability of the engine’s gasket system.

Performance and Alternative Design

In performance parts and alternative design components, the O-Ring Seal is often utilized to enhance the sealing capabilities of modified engine systems. Its flexibility and durability make it suitable for high-performance applications where standard seals may fail.

Leak Testing and Quadrant Cylinder Hardware

The O-Ring Seal is also used in leak test adapters and quadrant cylinder hardware gasket sets. It ensures that these components are tightly sealed, allowing for accurate leak detection and maintaining the pressure integrity of the quadrant cylinder hardware.

Conclusion

The Cummins 4010577 O-Ring Seal is a versatile and essential component for the Cummins engines listed, providing critical sealing solutions that help maintain the engines’ operational integrity. Its role in various engine systems, from fuel delivery to combustion chamber sealing, underscores its importance in ensuring the efficiency, reliability, and performance of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.