This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

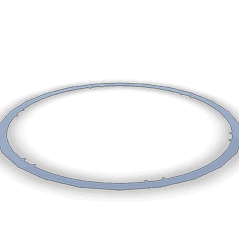

The Cummins 4015526 Liner Seal Ring is a component designed to enhance the operation of heavy-duty truck engines. Its role is significant in maintaining the integrity of the engine’s performance by ensuring proper sealing within the engine’s cylinder liners.

Basic Concepts of Liner Seal Rings

A Liner Seal Ring is a mechanical component used in internal combustion engines to create a seal between the cylinder liner and the engine block. This seal is vital for maintaining compression within the cylinder, which is necessary for efficient combustion. Additionally, it prevents oil from leaking into the combustion chamber, which could lead to contamination and reduced engine efficiency 1.

Purpose of the 4015526 Liner Seal Ring

This Cummins part plays a role in the operation of a truck engine by maintaining compression within the cylinder. This is achieved by creating a tight seal that prevents gas leakage during the combustion process. Furthermore, it helps in preventing oil from entering the combustion chamber, which ensures that the oil remains within the lubrication system where it is needed.

Key Features

The 4015526 is characterized by its material composition, which typically includes durable elastomers that can withstand high temperatures and pressures. Its design specifications are tailored to fit precisely within the engine’s cylinder liner, ensuring a secure and effective seal. Unique attributes of this seal ring may include anti-extrusion features that enhance its performance under demanding conditions.

Benefits

Using this part is associated with several benefits. These include improved engine efficiency due to effective compression maintenance, reduced maintenance requirements thanks to its durable construction, and enhanced durability that contributes to the overall longevity of the engine.

Installation Process

Proper installation of the Liner Seal Ring involves several steps. It begins with ensuring the cylinder liner is clean and free of debris. The seal ring should be lubricated before insertion to facilitate a smooth fit. Using the appropriate tools, the ring is then carefully placed into the groove of the cylinder liner. It is important to follow manufacturer guidelines to ensure a secure fit that will perform effectively under engine operation conditions.

Troubleshooting Common Issues

Common problems associated with Liner Seal Rings include oil leaks and compression loss. These issues can often be traced back to improper installation, wear and tear, or damage to the seal ring. Troubleshooting steps may involve inspecting the seal ring for signs of wear, ensuring it is properly seated, and replacing it if necessary to restore engine performance.

Maintenance Tips

To ensure the longevity and optimal performance of the 4015526, regular maintenance practices are recommended. This includes periodic inspection of the seal ring for signs of wear or damage, and adhering to manufacturer-recommended replacement intervals. Keeping the engine clean and well-lubricated also contributes to the seal ring’s durability and effectiveness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success. The company’s product offerings cater to various industries, including transportation, construction, and power generation, underscoring its reputation within the automotive industry.

Cummins Liner Seal Ring Part 4015526 Compatibility

The Cummins Liner Seal Ring part number 4015526 is a component designed to ensure the integrity of the engine’s cylinder walls. This seal ring is engineered to fit seamlessly within the engine’s architecture, providing a reliable barrier against oil leakage and maintaining optimal engine performance.

QSV91-G4 CM558/CM700 V102

The QSV91-G4 CM558/CM700 V102 engines are part of Cummins’ robust lineup, known for their durability and efficiency in various applications. The Liner Seal Ring part 4015526 is specifically designed to fit these engines, ensuring a tight seal that prevents oil from bypassing the cylinder walls. This compatibility is crucial for maintaining engine efficiency and longevity, as it helps to keep the oil within the lubrication system where it is needed most.

QSV91G

The QSV91G engine is another variant in Cummins’ extensive engine series. The Liner Seal Ring part 4015526 is engineered to fit this engine model as well, providing a precise seal that is essential for the engine’s operation. This seal ring is designed to withstand the high pressures and temperatures typical of engine environments, ensuring that the engine runs smoothly and efficiently.

By using the Cummins Liner Seal Ring part 4015526 in these engines, users can be assured of a reliable and effective sealing solution that contributes to the overall performance and durability of the engine.

Liner Seal Ring Component Usage

The Liner Seal Ring, identified by part number 4015526, is a component in the assembly and operation of engine systems, particularly in the context of the block, cylinder, and cylinder block.

In the engine assembly, the Liner Seal Ring is strategically positioned to ensure a secure and efficient seal between the cylinder and the cylinder block. This seal is fundamental for maintaining the integrity of the combustion process. By fitting snugly within the cylinder, the seal ring prevents any leakage of combustion gases, which could otherwise lead to a loss of power and efficiency.

Additionally, the Liner Seal Ring plays a significant role in managing the thermal expansion that occurs within the engine. As the engine operates, components expand due to heat. The seal ring’s design allows it to accommodate this expansion while still maintaining a tight seal, thus ensuring consistent performance across varying operating temperatures.

Furthermore, the interaction between the Liner Seal Ring and the cylinder block is pivotal for the overall structural integrity of the engine. The seal ring helps in distributing the forces generated during combustion more evenly across the cylinder block, reducing the risk of stress concentrations that could lead to component failure over time.

Conclusion

In summary, the Liner Seal Ring (part 4015526) is integral to the efficient and reliable operation of engine systems, contributing to both performance and durability through its role in sealing, thermal management, and structural support.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.