This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4065885 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts that contribute to the efficiency and reliability of truck operations. This Cummins part is specifically engineered to provide effective sealing solutions in various truck systems, ensuring optimal performance and longevity.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals play a role by preventing the leakage of fluids and gases, and they can be used in both dynamic and static applications. In dynamic applications, the O-Ring moves within the system to maintain the seal, whereas in static applications, it remains stationary. The effectiveness of an O-Ring Seal depends on its material properties, design, and the conditions under which it operates 1.

Purpose of the 4065885 O-Ring Seal in Truck Operations

The 4065885 O-Ring Seal is utilized in commercial trucks to ensure the integrity of seals within various systems. It is typically found in areas where fluid or gas containment is necessary, such as in the engine, transmission, or hydraulic systems. By providing a reliable seal, this part contributes to the efficient operation of these systems, helping to maintain performance and prevent leaks that could lead to system failure or inefficiency.

Key Features of the 4065885 O-Ring Seal

The 4065885 O-Ring Seal is characterized by its robust design and material composition. It is made from high-quality elastomers that offer durability and resistance to a wide range of chemicals and temperatures. This O-Ring Seal is also known for its flexibility, which allows it to conform to the surfaces it seals, ensuring a tight fit even under varying conditions. These features contribute to the seal’s ability to perform reliably in the demanding environment of a commercial truck 2.

Benefits of Using the 4065885 O-Ring Seal

Incorporating the 4065885 O-Ring Seal into truck maintenance and operation offers several advantages. Its design and material properties result in improved sealing efficiency, which can lead to enhanced system performance. The durability and resistance of the seal contribute to its longevity, reducing the frequency of replacements and maintenance costs. Additionally, the reliability of the 4065885 O-Ring Seal helps to ensure consistent truck operation, minimizing downtime.

Installation and Replacement Guidelines

To install or replace the 4065885 O-Ring Seal, it is important to follow a systematic approach. Begin by ensuring the mating surfaces are clean and free of debris. Use the appropriate tools to remove the old seal, if applicable, and inspect the groove for any damage. Lubricate the new O-Ring Seal with a compatible lubricant to facilitate installation. Carefully place the O-Ring into the groove, ensuring it is seated properly without twists or folds. Finally, reassemble the system and check for proper function.

Troubleshooting Common Issues with O-Ring Seals

Common problems with O-Ring Seals include leaks and wear. If a leak is detected, it may be due to improper installation, damage to the O-Ring, or incompatible materials. Wear can occur over time due to friction or exposure to harsh conditions. To address these issues, inspect the O-Ring and mating surfaces for damage, ensure correct installation practices are followed, and consider the operating conditions to select the appropriate O-Ring material.

Maintenance Tips for O-Ring Seals

Regular maintenance is key to prolonging the life of the 4065885 O-Ring Seal. This includes periodic inspections for signs of wear or damage, and cleaning the seal and mating surfaces to remove contaminants that could affect performance. It is also important to follow manufacturer recommendations for replacement intervals, as O-Ring Seals can degrade over time even if no immediate issues are apparent.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation. Cummins’ commitment to excellence is reflected in its parts, such as the 4065885 O-Ring Seal, which are engineered to deliver reliable performance in challenging environments.

O-Ring Seal 4065885 Compatibility with Cummins Engines

The O-Ring Seal part number 4065885, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This seal is crucial for maintaining the integrity of fluid systems by preventing leaks and ensuring that the engine operates efficiently.

QSK45 CM500 and QSK60 CM500

The O-Ring Seal 4065885 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in demanding applications. The seal fits precisely in areas where it is required to maintain fluid containment, ensuring that the engine’s performance is not compromised by leaks.

QSK60 G CM2358 K110

For the QSK60 G CM2358 K110 engine, the O-Ring Seal 4065885 is engineered to fit into specific components that require a high level of sealing. This engine, being a variant of the QSK60 series, benefits from the seal’s ability to withstand high pressures and temperatures, which are common in such high-performance engines.

QSK60G

The QSK60G engine also utilizes the O-Ring Seal 4065885. This seal is integral to the engine’s operation, providing a reliable barrier against fluid leaks in critical areas. Its design ensures that the engine maintains optimal performance and longevity, even under strenuous conditions.

Each of these engines relies on the O-Ring Seal 4065885 to maintain fluid integrity, ensuring that the engine operates efficiently and reliably. The seal’s compatibility across these models underscores its versatility and importance in Cummins’ engine lineup.

Role of Part 4065885 O-Ring Seal in Engine Systems

The part 4065885 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems. Its application is particularly significant in the following components:

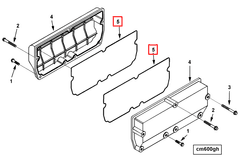

Cover

In the context of engine covers, the O-Ring Seal (part 4065885) is utilized to create a secure and leak-proof seal between the cover and the engine block. This ensures that no fluids or gases escape, which is essential for maintaining the engine’s operational efficiency and preventing contamination. The seal helps in retaining lubricants within the engine, thereby reducing the risk of wear and tear on internal components.

Cam Follower

For cam followers, the O-Ring Seal plays a role in sealing the interface between the cam follower and its housing. This is important for preventing the ingress of dirt and debris, which can lead to increased friction and potential damage to the cam and follower surfaces. Additionally, the seal helps in retaining lubricants, ensuring smooth operation and prolonging the lifespan of the cam follower.

In both applications, the O-Ring Seal (part 4065885) contributes to the overall reliability and performance of the engine system by providing a robust barrier against external contaminants and internal fluid loss.

Conclusion

The 4065885 O-Ring Seal is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its robust design, material composition, and compatibility with various engine models make it an essential part for ensuring the efficiency and reliability of truck operations. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the longevity and performance of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.