This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4095894 O-Ring Seal is a component designed to ensure the integrity of seals in various systems within commercial trucks. Its role is significant in maintaining the efficiency and reliability of truck operations, particularly in environments where durability and resistance to harsh conditions are paramount.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal shape made from elastomer materials. Its primary function in mechanical systems is to create a seal between two or more parts. When compressed, the O-Ring deforms to fill the gap between the mating surfaces, preventing the leakage of fluids or gases. This mechanism is vital in applications where maintaining pressure and preventing contamination are necessary 1.

Purpose of the 4095894 O-Ring Seal in Truck Operations

This Cummins part is utilized in specific areas within commercial trucks to support various systems. It is commonly applied in fuel systems, hydraulic systems, and engine components where sealing is required to maintain system integrity and performance. By ensuring that fluids and gases remain contained within their designated pathways, the O-Ring contributes to the overall efficiency and reliability of the truck’s operation.

Key Features of the 4095894 O-Ring Seal

The design and material characteristics of the 4095894 O-Ring Seal are tailored to meet the demanding requirements of commercial truck applications. Crafted from high-quality elastomer materials, it exhibits durability and resistance to a wide range of chemicals and temperatures. This resilience ensures that the seal remains effective under the varied and often harsh conditions encountered in truck operations. Additionally, its compatibility with other components is a key feature, ensuring seamless integration into existing systems.

Benefits of Using the 4095894 O-Ring Seal

Utilizing this part offers several advantages. It contributes to improved system efficiency by ensuring that seals remain intact, thereby preventing leaks that could lead to system inefficiencies or failures. Reduced maintenance needs are another benefit, as the seal’s durability and resistance to wear and environmental factors mean it requires less frequent replacement. Furthermore, its reliability in harsh operating conditions enhances the overall performance and longevity of the truck’s systems.

Installation and Maintenance Guidelines

Proper installation of the 4095894 O-Ring Seal is crucial for its effectiveness. This involves preparing the sealing surface to ensure it is clean and free from imperfections that could compromise the seal. Torque specifications should be adhered to during installation to ensure the O-Ring is compressed adequately without being overtightened, which could damage the seal. Regular maintenance checks are recommended to ensure the seal remains in optimal condition, with any signs of wear or damage addressed promptly to prevent system failures 2.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks or failures, often due to wear, improper installation, or exposure to incompatible chemicals. Troubleshooting these issues involves inspecting the seal and its mating surfaces for signs of damage or misalignment. Ensuring that the O-Ring is made from a material compatible with the fluids or gases it is sealing and that it is installed correctly can help resolve many issues. In cases where the O-Ring has deteriorated, replacement with a compatible seal is necessary to restore system integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial vehicle, equipment, and engine markets. Its extensive product range includes engines, components, and aftermarket parts, all designed to meet the rigorous demands of various industries. Cummins’ dedication to excellence in engine and component manufacturing underscores its role as a trusted partner in the commercial vehicle industry.

Cummins O-Ring Seal 4095894 Compatibility

The O-Ring Seal part number 4095894, manufactured by Cummins, is designed to fit seamlessly within various engine models. This seal is crucial for maintaining the integrity of the engine’s system by preventing leaks and ensuring that the engine operates efficiently.

QST30 CM552 Engines

The O-Ring Seal 4095894 is specifically engineered to fit the QST30 CM552 engines. This seal is essential for the proper functioning of the engine, providing a reliable barrier against fluid leaks and maintaining the necessary pressure within the engine’s components. Its precise fit ensures that the engine can perform optimally without any risk of contamination or loss of pressure.

Grouped Engine Compatibility

While the primary focus is on the QST30 CM552 engines, it is important to note that the O-Ring Seal 4095894 is also compatible with other Cummins engines within the same engine family. This compatibility ensures that the seal can be used across multiple engine models, providing a standardized solution for maintaining engine performance and reliability.

By using the O-Ring Seal 4095894, engine operators can be confident that their engines will remain leak-free and efficient, contributing to the overall longevity and effectiveness of the engine system.

Role of Part 4095894 O-Ring Seal in Engine Systems

The 4095894 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. In the context of an oil pan, this seal ensures that oil remains contained within the pan, preventing leaks that could lead to oil loss and potential engine damage. When integrated into the oil pan’s design, the O-ring creates a tight seal around the pan’s edges and any connecting points, such as bolts or gaskets, enhancing the overall reliability of the oil containment system.

In remote oil systems, the 4095894 O-Ring Seal plays a significant role in maintaining the seal between the remote oil pan and its mounting surface. This is particularly important in high-performance or custom engine builds where the oil pan may be relocated for better weight distribution or clearance. The seal prevents oil from escaping at the connection points, ensuring that the oil system operates efficiently and without contamination.

For drain systems, the 4095894 O-Ring Seal is used to ensure a secure seal around the drain plug or any other drainage points within the engine system. This is essential during oil changes or maintenance procedures, as it prevents oil from leaking out prematurely and ensures that the draining process is clean and controlled.

In plumbing applications within the engine, such as oil lines and fittings, the 4095894 O-Ring Seal is employed to create a leak-proof connection. This is vital for maintaining the proper oil pressure and flow throughout the engine, which is necessary for lubrication and cooling of moving parts. The seal helps in preventing oil leaks at connection points, which could otherwise lead to inefficient oil circulation and potential engine wear.

Overall, the 4095894 O-Ring Seal is a fundamental component in ensuring the sealing integrity of various engine systems, from the oil pan to remote oil setups and drain mechanisms, contributing to the engine’s overall performance and longevity.

Conclusion

The Cummins 4095894 O-Ring Seal is a critical component in maintaining the efficiency and reliability of commercial truck and engine systems. Its design, material characteristics, and compatibility with various engine models make it an essential part for preventing leaks and ensuring system integrity. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this seal, contributing to the overall performance and longevity of the engine system.

SPECIFICATIONS

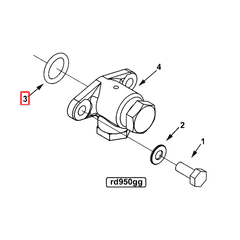

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.