This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4096216 O-Ring Seal is a component designed for use in commercial trucks. Its primary purpose is to provide a reliable seal in various systems and components within these vehicles. This seal is integral to maintaining the integrity of fluid systems, ensuring that fluids such as coolant, oil, and fuel remain contained within their respective pathways 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 2.

Role of the 4096216 O-Ring Seal in Truck Operation

The Cummins 4096216 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in critical systems. It is commonly associated with fuel systems, where it helps maintain the seal around injectors or other fuel delivery components. Additionally, it may be used in cooling systems to prevent coolant leaks, thus contributing to the overall efficiency and reliability of the truck’s engine and ancillary systems 3.

Key Features of the 4096216 O-Ring Seal

The Cummins 4096216 O-Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. It is typically made from durable materials such as nitrile rubber, which offers excellent resistance to oils, fuels, and various chemicals. The seal is designed to withstand high pressures and temperatures, ensuring reliable performance in demanding environments. Its precise manufacturing tolerances ensure a snug fit within the designated grooves, enhancing its sealing capabilities 4.

Benefits of Using the 4096216 O-Ring Seal

Utilizing the Cummins 4096216 O-Ring Seal offers several benefits. It provides improved sealing efficiency, reducing the risk of leaks and ensuring that fluids remain within their intended pathways. The seal’s durability contributes to its longevity, minimizing the need for frequent replacements. Additionally, its resistance to various operating conditions, including exposure to chemicals and extreme temperatures, enhances the overall reliability of the truck’s systems 5.

Installation Considerations

Proper installation of the Cummins 4096216 O-Ring Seal is crucial for ensuring optimal performance and longevity. It should be installed in a clean, lubricated groove to facilitate easy seating and prevent damage to the seal. Care should be taken to avoid over-lubrication, as excessive lubricant can lead to seal extrusion. Following manufacturer guidelines for torque specifications when assembling components is also important to ensure the seal is properly compressed without being overtightened 6.

Common Issues and Troubleshooting

Common issues with O-Ring Seals include leaks and degradation over time. Leaks may occur due to improper installation, damage to the seal, or wear and tear. Degradation can result from exposure to incompatible fluids or extreme operating conditions. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, ensuring proper installation, and replacing the seal if necessary. Regular maintenance and inspection can help identify issues before they lead to significant problems 7.

Maintenance Tips

Maintaining the Cummins 4096216 O-Ring Seal involves regular inspection for signs of wear, such as cracking or deformation. Inspection intervals should be aligned with the truck’s maintenance schedule, with more frequent checks for vehicles operating in harsh conditions. Signs of wear may indicate the need for replacement to prevent leaks and ensure system integrity. Keeping the seal and its groove clean and free of contaminants also contributes to its longevity and performance 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 9.

Compatibility with Cummins Engines

This Cummins part is designed to fit seamlessly within the engine systems of several Cummins models. It is crucial for ensuring the integrity of the engine’s sealing mechanisms, preventing leaks and maintaining optimal performance.

B3.3 Engine

The B3.3 engine benefits from the O-Ring Seal, which is integral to its sealing system. This part ensures that the engine operates efficiently by preventing unwanted fluid leaks, thereby maintaining the engine’s internal pressure and performance.

QSB3.3 CM2150 and QSB3.3 CM2250 EC Engines

The O-Ring Seal is also compatible with the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines. These engines rely on the precision and durability of this seal to maintain their sealing integrity. The part’s design ensures that it fits perfectly within the engine’s architecture, providing a reliable barrier against leaks and maintaining the engine’s operational efficiency.

By integrating this O-Ring Seal into these engines, Cummins ensures that the engines can operate under various conditions without compromising on performance or reliability.

Role of Part 4096216 O-Ring Seal in Engine Systems

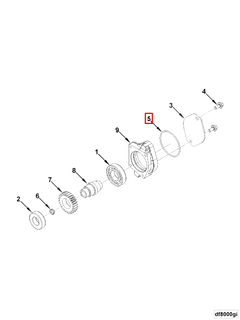

The 4096216 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. In the Accessory Drive Kit, it ensures that the seals around driven components remain intact, preventing fluid leaks and maintaining proper lubrication.

Within the Belt Tensioner assembly, the O-Ring Seal helps to keep the tensioner mechanism sealed, which is essential for consistent belt tension and reliable operation of accessories like the alternator and water pump.

In the Complete Engine Gasket Kit, the O-Ring Seal complements traditional gaskets by providing additional sealing at critical points, such as oil passages and coolant channels, enhancing the overall seal integrity of the engine.

For the Fan Drive and Fan Drive Idler, the O-Ring Seal is used to prevent coolant or oil leaks around the rotating components, ensuring that the cooling system operates efficiently without contamination.

In the Front Gear Train Accessory Drive and Front Gear Train Accessory Mounting, the O-Ring Seal plays a role in sealing the interfaces where accessories connect to the gear train, preventing lubricant loss and ingress of contaminants.

The Front Power Take-Off system benefits from the O-Ring Seal by maintaining a tight seal around the output shaft, which is vital for transferring power to external equipment without leakage.

In a general Gasket Kit, the O-Ring Seal is often included to provide additional sealing where standard gaskets may not suffice, particularly in areas with dynamic movement or high pressure.

The Idler Pulley assembly uses the O-Ring Seal to maintain the seal around the pulley shaft, ensuring that the belt tracking remains consistent and that no lubricant is lost from the pulley bearings.

Lastly, in an Overhaul Kit, the O-Ring Seal is a common component used to refresh all seals within the engine, providing peace of mind that all sealing surfaces are in optimal condition post-overhaul.

Conclusion

The Cummins 4096216 O-Ring Seal is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its durable construction, precise fit, and resistance to various operating conditions make it an essential part for ensuring the integrity of fluid systems. Proper installation, regular maintenance, and timely replacement are key to maximizing the performance and longevity of this seal.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Cummins Inc. Service Manual (5504465).

↩ -

Cummins Inc. Service Manual (5504465).

↩ -

Cummins Inc. Service Manual (5504465).

↩ -

Cummins Inc. Service Manual (5504465).

↩ -

Cummins Inc. Service Manual (5504465).

↩ -

Cummins Inc. Service Manual (5504465).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.