This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4313302 O-Ring Seal Assembly is a component designed for use in commercial trucks. It plays a role in ensuring the integrity of various systems within these vehicles. By maintaining proper seals, it contributes to the efficient operation and longevity of truck components.

Basic Concepts of O-Ring Seal Assembly

An O-Ring Seal Assembly is a type of gasket consisting of a ring of elastomer with a round cross-section. It functions by creating a seal between two or more parts, preventing the leakage of fluids or gases. These assemblies are widely used in mechanical systems to ensure that components remain sealed under various operating conditions 1.

Purpose of the 4313302 O-Ring Seal Assembly

This Cummins part is specifically designed to play a role in the sealing mechanisms within a truck’s engine or other systems. It ensures that fluids and gases remain contained within their designated pathways, which is important for maintaining system efficiency and preventing contamination.

Key Features

The 4313302 is constructed from high-quality elastomer materials, chosen for their durability and resistance to various chemicals and temperatures. Its design specifications include precise dimensions to ensure a proper fit and effective seal. Unique attributes may include reinforced materials for added strength or specialized coatings to enhance performance in harsh environments.

Benefits

The advantages of using this part include improved system performance through reliable sealing, increased durability under demanding conditions, and enhanced efficiency by preventing leaks that could lead to system failures or inefficiencies.

Installation Process

Proper installation of the 4313302 involves several steps. First, the mating surfaces should be cleaned to remove any debris or old sealant. The O-ring should then be lubricated with a compatible lubricant to facilitate installation and reduce the risk of damage. It is important to handle the O-ring carefully to avoid distortion. Once in place, the components should be assembled according to the manufacturer’s specifications, ensuring that the O-ring is not over-compressed, which could lead to failure.

Troubleshooting Common Issues

Common problems with O-Ring Seal Assemblies can include leaks due to improper installation, degradation of the elastomer material, or damage from excessive heat or chemical exposure. Troubleshooting these issues may involve inspecting the O-ring for signs of wear or damage, ensuring that it is properly seated, and replacing it if necessary. Regular checks and maintenance can help identify and address these issues before they lead to more significant problems 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 4313302, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the mating surfaces to prevent contamination, and replacing the O-ring as part of routine maintenance schedules or when signs of degradation are observed.

Cummins: A Brief Overview

Cummins is a well-established manufacturer in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has built a reputation for reliability and performance. Their product lineup includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking.

Compatibility of 4313302 with Cummins Engines

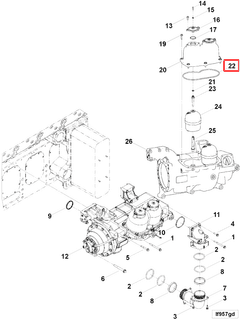

This part is designed to fit seamlessly with the QSK95 CM2350 engines, specifically the K111 and K113 variants. This seal assembly is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks or failures in the critical areas where it is installed.

For the QSK95 CM2350 K111 and K113 engines, the 4313302 is engineered to provide a reliable seal in high-pressure environments. Its precision-engineered design ensures that it fits perfectly within the engine’s architecture, providing a robust barrier against oil, fuel, and other fluids. This compatibility is important for maintaining engine performance and longevity.

Role of 4313302 in Engine Systems

The 4313302 is integral to maintaining the integrity and efficiency of various engine systems, particularly those involving fluid dynamics and filtration.

In the context of the filter system, the O-Ring Seal Assembly ensures a tight seal between the filter housing and the filter element. This seal is essential for preventing bypass, where unfiltered contaminants could enter the engine’s lubrication system, potentially leading to increased wear and reduced engine life.

When considering the lubricating oil system, the O-Ring Seal Assembly plays a significant role in maintaining the pressure and flow of oil throughout the engine. By ensuring a secure seal in the oil passages, it helps in delivering clean, pressurized oil to critical engine components, thus enhancing lubrication and cooling efficiency.

In the lubricating oil filter head, the O-Ring Seal Assembly is used to create a reliable seal between the filter head and the engine block or the filter housing. This seal is vital for maintaining the structural integrity of the filtration system and ensuring that the oil filter performs its function effectively without leaks.

Finally, within the lubricating oil filter kit, the O-Ring Seal Assembly is often included to facilitate the proper installation and sealing of new filter elements. This ensures that the filter kit can be installed correctly, providing optimal performance and longevity for the engine’s lubrication system.

Conclusion

The 4313302 O-Ring Seal Assembly by Cummins is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its high-quality construction, precise design, and compatibility with specific engine models make it an essential part for ensuring the integrity of sealing systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.