This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4325615 O-Ring Seal is a vital component designed to maintain the integrity of fluid systems in commercial trucks. It plays a role in preventing leaks and ensuring system efficiency, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section. It functions by creating a seal when compressed between two surfaces, preventing the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 4325615 O-Ring Seal

This Cummins part is specifically designed for use in the fluid systems of commercial trucks. It is associated with components such as fuel injectors, where it helps maintain the seal between moving parts and stationary components, ensuring that fuel is delivered efficiently without leakage 2.

Key Features

The Cummins 4325615 O-Ring Seal is characterized by its material composition, typically made from durable elastomers such as nitrile or fluorocarbon, which offer resistance to oils, fuels, and other chemicals. Its dimensions and design are tailored to fit precisely within the specified applications, ensuring a reliable seal under various operating conditions 3.

Benefits

This part provides several benefits, including enhanced sealing efficiency, which helps in maintaining system pressure and preventing fluid leaks. Its durability ensures long-term performance, while its resistance to various operating conditions, such as temperature fluctuations and chemical exposure, contributes to its reliability in commercial truck applications.

Installation Considerations

Proper installation of the Cummins 4325615 O-Ring Seal is vital to ensure its effectiveness. Guidelines recommend cleaning the sealing surfaces to remove any contaminants that could compromise the seal. The O-Ring should be lubricated with a compatible lubricant to facilitate installation and reduce the risk of damage. Careful handling is necessary to avoid distorting the O-Ring, which could lead to improper sealing.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which can be caused by improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps involve inspecting the O-Ring for signs of damage or deformation, ensuring that the sealing surfaces are clean and free of contaminants, and verifying that the O-Ring is the correct size and material for the application.

Maintenance Tips

Regular maintenance of the Cummins 4325615 O-Ring Seal involves periodic inspection for signs of wear or damage. It is advisable to replace the O-Ring during routine maintenance or when performing repairs on associated components to prevent unexpected failures. Keeping the sealing surfaces clean and free of debris also contributes to the longevity and reliability of the O-Ring Seal.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the Cummins 4325615 O-Ring Seal, which is designed to meet the demanding requirements of commercial vehicle applications.

Cummins O-Ring Seal 4325615 in ISV Engines

The Cummins O-Ring Seal part number 4325615 is a critical component in various ISV (Infiniti Service Vehicle) engines, specifically those manufactured by Nissan. This seal is integral to ensuring the engine’s operational integrity by preventing leaks and maintaining pressure within the system.

In ISV engines, the O-Ring Seal 4325615 is typically used in areas where a secure seal is necessary to prevent fluid or gas from escaping. Its placement is crucial, often found in the engine’s oil system, connecting rods, or other high-pressure zones. The seal’s design and material ensure it can withstand the high temperatures and pressures typical in engine environments, providing a reliable barrier against leaks.

The use of this specific O-Ring Seal in ISV engines highlights Cummins’ commitment to quality and durability. The seal’s precision fit and robust construction make it a preferred choice for maintaining the efficiency and longevity of the engine. Its application across various ISV models underscores its versatility and effectiveness in different engine configurations.

Role of Part 4325615 O-Ring Seal in Engine Systems

The part 4325615 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. In the Air Transfer Tube, this O-Ring Seal ensures a tight and leak-free connection between the tube and its mating surfaces, which is essential for optimal air flow and pressure maintenance within the engine.

When it comes to Connections throughout the engine, the O-Ring Seal plays a significant role in preventing air or fluid leaks at joints and interfaces. This is particularly important in high-pressure or high-vacuum systems where even minor leaks can lead to performance issues.

In the context of Air Transfer systems, the O-Ring Seal is used to secure connections in pathways that route air to various components, ensuring that the air reaches its destination without loss, which is vital for engine efficiency and performance.

For Service Kits, the inclusion of the O-Ring Seal is standard practice. These kits are designed to refresh and repair various engine components, and the O-Ring Seal is often a key element in restoring the seal integrity of aged or worn parts.

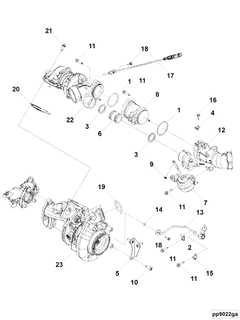

In a Turbocharger Kit, the O-Ring Seal is employed to ensure that the connections between the turbocharger and the engine are secure. This is important for maintaining the boost pressure and preventing any unwanted air leaks that could affect turbocharger performance.

Lastly, in an Upper Engine Gasket Kit, the O-Ring Seal complements traditional gaskets by providing additional sealing at dynamic or hard-to-seal points. This ensures that the upper portion of the engine, which includes critical components like the cylinder head and intake manifold, operates within designed parameters without leaks.

Conclusion

The Cummins 4325615 O-Ring Seal is a critical component in the fluid systems of commercial trucks, ensuring the integrity and efficiency of various engine systems. Its durable construction, precise fit, and resistance to harsh operating conditions make it a reliable choice for maintaining the performance and reliability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.