This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4332188 D Ring Seal is a component utilized in commercial trucks, playing a role in maintaining the integrity of various systems by preventing leaks and ensuring proper function. Its application is significant in environments where durability and reliability are paramount.

Basic Concepts of D Ring Seals

D Ring Seals are mechanical seals designed to create a barrier between two surfaces to prevent the leakage of fluids or gases. They operate by utilizing a flexible ring that conforms to the surfaces it contacts, creating a seal 1. These seals are commonly used in applications where there is relative motion between the sealing surfaces, such as in rotating shafts or reciprocating components. The design of a D Ring Seal typically includes a metal ring with a flexible elastomeric coating, which allows it to adapt to the contours of the mating surfaces while maintaining a tight seal 2.

Role of the 4332188 D Ring Seal in Truck Operation

This Cummins part is involved in the operation of commercial trucks by ensuring the sealing integrity of specific systems or components. It is associated with areas where fluid or gas containment is necessary to maintain system efficiency and prevent contamination. The seal’s role is to withstand the pressures and temperatures of the truck’s operating environment while providing a reliable barrier against leaks.

Key Features of the 4332188 D Ring Seal

The 4332188 D Ring Seal boasts several key features that enhance its performance. Its material composition typically includes a durable metal core with an elastomeric outer layer, chosen for its flexibility and resistance to wear. The design attributes of the seal, such as its cross-sectional shape and the precision of its fit, contribute to its effectiveness in sealing applications. Additionally, any unique characteristics, such as reinforced edges or specialized coatings, further improve its performance in demanding conditions 3.

Benefits of Using the 4332188 D Ring Seal

Incorporating the 4332188 D Ring Seal into truck maintenance and operation offers several advantages. These include improved system efficiency due to effective sealing, enhanced longevity of the seal itself and the components it protects, and increased reliability of the truck’s systems. The seal’s design and material properties contribute to these benefits by ensuring a consistent and durable seal under varying operational conditions.

Installation Considerations

When installing the 4332188 D Ring Seal, it is important to follow guidelines and best practices to ensure proper function. Preparation steps may include cleaning the sealing surfaces and inspecting the seal for any defects. The tools required for installation typically include those necessary for precise placement and adjustment of the seal. Common pitfalls to avoid during installation include improper sizing, incorrect orientation, and damage to the seal during handling.

Troubleshooting Common Issues

Common problems associated with D Ring Seals can include leaks, wear, and failure due to environmental factors or mechanical stress. Practical solutions for addressing these issues involve identifying the root cause of the problem, whether it be improper installation, material degradation, or operational stress. Tips for diagnosing seal failures include visual inspection for signs of wear or damage and testing for leaks under operational conditions. The steps to take for replacement involve careful removal of the failed seal and installation of a new one, following the manufacturer’s guidelines.

Maintenance Tips

Regular maintenance of the 4332188 D Ring Seal is recommended to ensure optimal performance and longevity. This includes routine inspections for signs of wear or damage, such as cracks or deformation, and cleaning the seal and its mating surfaces to remove contaminants that could affect sealing efficiency. Addressing any issues promptly can help prevent more significant problems and extend the life of the seal and the systems it protects.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to manufacturing high-quality truck components is evident in its extensive product range and the performance of its parts, including the 4332188 D Ring Seal.

Application in QSK95 Engines

The 4332188 D Ring Seal is specifically engineered to fit within the QSK95 engine series. These engines, known for their robust performance and reliability, include models such as the QSK95 CM2350 K111 and QSK95 CM2350 K113. The seal’s role in these engines is to provide a tight seal at critical junctures, ensuring that no contaminants or fluids escape, which could otherwise lead to engine damage or reduced performance.

Importance of the Seal in Engine Performance

In the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the 4332188 D Ring Seal is integral to maintaining the pressure and cleanliness of the engine’s internal systems. Its placement and design are critical to the engine’s ability to operate under high stress and varying conditions. The seal’s material and construction are specifically chosen to withstand the extreme temperatures and pressures found within these engines, ensuring durability and consistent performance over time.

Ensuring Engine Reliability

By using the 4332188 D Ring Seal in the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, operators can be confident in the engine’s reliability and efficiency. This seal is a testament to Cummins’ commitment to providing high-quality components that meet the rigorous demands of their engine designs. Its proper installation and maintenance are crucial for the longevity and optimal performance of these engines.

Role of the 4332188 D Ring Seal in Engine Systems

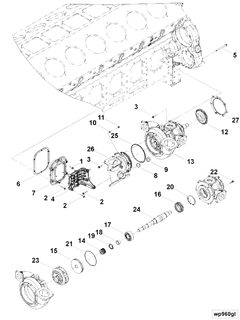

The 4332188 D Ring Seal is integral to the efficient operation and maintenance of various engine components. Its application spans across multiple systems, ensuring optimal performance and longevity.

Connection Systems

In connection systems, the D Ring Seal is employed to create a secure and leak-proof seal between mating surfaces. This is particularly important in high-pressure environments where any leakage can lead to system failure. The seal ensures that fluids, whether coolants or lubricants, are contained within the system, maintaining the integrity of the connection.

Raw Water Outlet

At the raw water outlet, the D Ring Seal plays a significant role in preventing water ingress and ensuring that the outlet operates efficiently. This is vital for engines that rely on raw water for cooling, as any compromise in the seal can lead to reduced cooling efficiency and potential engine overheating.

Plumbing Systems

Within plumbing systems, the D Ring Seal is used to maintain the integrity of fluid pathways. Whether it’s fuel, coolant, or lubricant, the seal ensures that these fluids are directed correctly without any leakage. This is essential for maintaining system pressure and ensuring that all components receive the necessary fluids for operation.

Oil Cooler Water Systems

In oil cooler water systems, the D Ring Seal is crucial for separating the oil and water circuits while allowing heat exchange. This ensures that the oil remains cool, enhancing engine performance and longevity. The seal prevents any cross-contamination between the oil and water, which could otherwise lead to system failure.

Service Kits

When included in service kits, the D Ring Seal is often a replacement part aimed at restoring system integrity. Over time, seals can degrade due to exposure to various fluids and temperatures. Replacing the D Ring Seal during maintenance ensures that the system continues to operate efficiently and prevents future leaks.

Tube Kits

In tube kits, the D Ring Seal is used to ensure that connections between tubes are secure and leak-free. This is particularly important in systems where tubes carry high-pressure fluids. The seal helps maintain system pressure and ensures that fluids are delivered to their intended destinations without any loss.

Water Pump Kits

Within water pump kits, the D Ring Seal is employed to ensure that the pump operates efficiently by maintaining a seal around moving parts. This is essential for preventing leaks and ensuring that the pump can deliver the necessary flow rates for engine cooling. The seal also helps in reducing wear on moving parts by preventing fluid ingress.

Conclusion

The Cummins 4332188 D Ring Seal is a critical component in the maintenance and operation of commercial trucks and engines, ensuring system integrity, efficiency, and reliability. Its proper installation, maintenance, and replacement are essential for the optimal performance and longevity of the systems it protects.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.