This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4349726 Diamond Ring Seal, a component manufactured by Cummins, is integral to the commercial truck industry. This seal is employed in various truck applications to ensure efficient vehicle operation. Seals are vital in heavy-duty truck operations, maintaining system integrity, preventing leaks, and sustaining pressure within the system. The 4349726 Diamond Ring Seal is engineered to withstand the demanding conditions of commercial truck environments.

Basic Concepts of Diamond Ring Seals

A Diamond Ring Seal is a mechanical seal with a unique design for enhanced performance. It comprises a stationary seat and a rotating seal ring, often featuring a diamond pattern on the sealing surface. This pattern aids in evenly distributing wear across the seal face, thereby improving durability and performance. Diamond Ring Seals are typically made from materials like carbon, ceramic, or metal, selected for their hardness, thermal stability, and resistance to wear and corrosion 1.

Purpose of the 4349726 Diamond Ring Seal in Truck Operations

This Cummins part is crucial in truck operations, providing a reliable seal in systems where fluid dynamics and pressure are significant. It is commonly used in engine cooling systems, transmission systems, and hydraulic systems. By maintaining a secure seal, it prevents fluid leaks, ensures system efficiency, and protects components from contamination 2.

Key Features of the 4349726 Diamond Ring Seal

The 4349726 Diamond Ring Seal is notable for its robust design and material properties. The diamond pattern on the sealing surface is a distinctive feature that enhances wear distribution and longevity. Additionally, the seal is constructed from high-quality materials that offer excellent resistance to wear, corrosion, and thermal stress. These attributes contribute to the seal’s reliable performance in demanding truck applications 3.

Benefits of Using the 4349726 Diamond Ring Seal

Incorporating this part into truck maintenance and operation offers several advantages. Its durable construction and efficient sealing capabilities contribute to the overall reliability and efficiency of the truck’s systems. The seal’s design helps in reducing maintenance intervals by providing long-lasting performance, which can lead to cost savings over time.

Installation and Maintenance Guidelines

Proper installation of the 4349726 Diamond Ring Seal is crucial for its effectiveness. It should be installed according to the manufacturer’s guidelines, ensuring that all mating surfaces are clean and free from debris. Regular maintenance, including periodic inspection for wear or damage, is recommended to ensure the longevity and optimal performance of the seal. Following these guidelines can help in maximizing the seal’s service life and maintaining system integrity.

Troubleshooting Common Issues

Common problems associated with Diamond Ring Seals may include leaks, wear, or failure to seal properly. Troubleshooting these issues often involves inspecting the seal and its mating surfaces for damage or misalignment. In cases where the seal is worn or damaged, replacement may be necessary. Diagnosing seal-related issues requires a thorough understanding of the system’s operation and the seal’s role within it.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s engine components, including the 4349726 Diamond Ring Seal, are designed to meet the rigorous demands of heavy-duty applications, reflecting Cummins’ dedication to excellence and customer satisfaction.

Diamond Ring Seal Part 4349726 in Cummins Engines

The Diamond Ring Seal part number 4349726 is a critical component in the Cummins QSK95 CM2350 engines, specifically in the variants K111 and K113. This seal plays a pivotal role in ensuring the integrity of the engine’s sealing system, which is essential for maintaining optimal performance and preventing leaks.

Application in Cummins QSK95 CM2350 K111

In the Cummins QSK95 CM2350 K111 engine, the Diamond Ring Seal part 4349726 is utilized in areas where high-pressure sealing is required. This seal is designed to withstand the rigorous conditions within the engine, providing a reliable barrier against oil and other fluids. Its placement is crucial for maintaining the engine’s efficiency and longevity, as it helps to prevent contamination and ensure that the engine operates smoothly.

Application in Cummins QSK95 CM2350 K113

Similarly, in the Cummins QSK95 CM2350 K113 engine, the Diamond Ring Seal part 4349726 is employed in high-stress sealing applications. This engine variant, like the K111, relies on this seal to maintain the integrity of its sealing system. The seal’s design allows it to adapt to the dynamic conditions within the engine, ensuring that it provides a consistent and effective seal over time. This is vital for the engine’s performance and for minimizing the risk of leaks and other issues that could arise from inadequate sealing.

Importance of the Diamond Ring Seal

The Diamond Ring Seal part 4349726 is integral to the overall functionality of the Cummins QSK95 CM2350 engines. Its role in providing a robust seal is essential for the engines’ operation, as it helps to maintain the necessary pressure and prevent the ingress of contaminants. This seal’s design and material composition make it suitable for the demanding environments within these engines, ensuring that they can perform reliably and efficiently over extended periods.

Role of Part 4349726 Diamond Ring Seal in Engine Systems

The 4349726 Diamond Ring Seal is a critical component in various engine systems, ensuring optimal performance and reliability. Its primary function is to create a secure seal between moving and stationary parts, preventing leaks and maintaining system integrity.

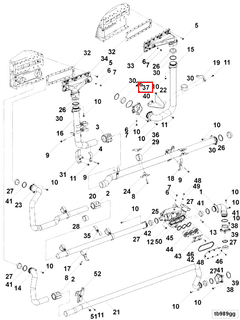

Auxiliary Cooling System

In the auxiliary cooling system, the Diamond Ring Seal is used at connection points between the auxiliary cooling inlet and the engine block. This seal ensures that coolant flows efficiently without any leakage, which is vital for maintaining the engine’s temperature within safe operating limits.

Gasket Kit and Housing

When integrated into a gasket kit, the Diamond Ring Seal plays a significant role in the housing assembly. It provides a robust seal between the housing and the engine block, preventing coolant or oil from escaping. This is particularly important in high-pressure environments where even minor leaks can lead to significant issues.

Thermostat and Service Kit

In the context of a service kit, the Diamond Ring Seal is often found in conjunction with the thermostat. It ensures that the thermostat housing is securely sealed, allowing the thermostat to regulate the engine’s temperature effectively. A reliable seal here prevents coolant loss and ensures consistent engine performance.

Tube Kit and Water Pump Kit

The Diamond Ring Seal is also utilized in tube kits and water pump kits. In these applications, it seals the connections between various tubes and the water pump, ensuring that the cooling system operates without leaks. This is essential for the efficient circulation of coolant, which is crucial for dissipating heat generated by the engine.

Overall System Integrity

Across all these applications, the 4349726 Diamond Ring Seal contributes to the overall integrity of the engine system. By providing reliable seals at critical connection points, it helps maintain the efficiency and longevity of the engine components.

Conclusion

The 4349726 Diamond Ring Seal is a vital component in the commercial truck industry, particularly in Cummins engines. Its robust design, material properties, and unique sealing pattern make it suitable for demanding environments. The seal’s role in preventing leaks, maintaining system pressure, and protecting components from contamination is crucial for the efficient operation of truck engines. Proper installation, regular maintenance, and understanding of common issues associated with this seal are essential for maximizing its performance and longevity.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.