This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Diamond Ring Seal 4349789, a specialized component manufactured by Cummins, plays a significant role in the operation of commercial trucks. This seal contributes to the efficiency and reliability of various truck systems, making it a crucial part for maintaining optimal truck performance 1.

Basic Concepts of Diamond Ring Seals

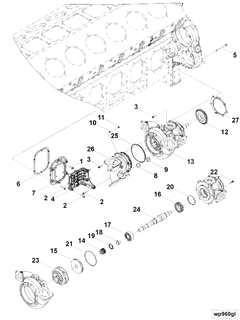

A Diamond Ring Seal is a type of mechanical seal designed to prevent leakage between rotating and stationary parts. Its structure typically includes a stationary seat, a rotating ring, and a sealing element. The seal functions by creating a barrier that prevents fluid or gas from escaping, ensuring that systems operate under the correct pressure and conditions 2.

Purpose of the 4349789 Diamond Ring Seal in Truck Operations

This Cummins part is utilized in commercial trucks to maintain the integrity of various systems where sealing is required. It is commonly applied in fuel systems, hydraulic systems, and other critical areas where preventing leaks is important for the system’s performance and safety. By ensuring a tight seal, it helps in maintaining system efficiency and reducing the risk of contamination or failure 3.

Key Features of the 4349789 Diamond Ring Seal

The 4349789 Diamond Ring Seal is characterized by its robust material composition, which typically includes high-grade metals and advanced polymers. Its design elements are tailored to withstand high pressures and temperatures, common in truck operations. The manufacturing specifications ensure precision and reliability, making it a durable component for demanding environments.

Benefits of Using the 4349789 Diamond Ring Seal

Utilizing this part offers several advantages. It provides enhanced sealing performance, which is vital for maintaining system pressure and efficiency. Its durability ensures long-term reliability, reducing the frequency of replacements. Additionally, its design contributes to the overall reliability of truck systems, supporting consistent performance in various operating conditions.

Installation Guidelines

Proper installation of this Cummins part is important for its performance and longevity. The process involves cleaning the sealing surfaces, ensuring the seal is correctly aligned, and securing it in place without over-tightening. Following these steps helps in achieving an effective seal and preventing damage to the component or surrounding parts.

Maintenance Tips

To prolong the service life of the 4349789 Diamond Ring Seal, regular inspection and cleaning are recommended. Checking for signs of wear or damage and ensuring the seal remains free from contaminants can help in maintaining its effectiveness. Replacement should be considered if any degradation is observed, to prevent potential system failures.

Troubleshooting Common Issues

Common problems with the 4349789 Diamond Ring Seal may include leaks or reduced sealing efficiency. These issues can often be traced back to improper installation, wear and tear, or contamination. Addressing these problems may involve re-evaluating the installation process, cleaning the seal and its surroundings, or replacing the seal if necessary.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the automotive industry, known for its high-quality truck components. With a history of innovation and commitment to excellence, Cummins has established itself as a trusted provider of reliable and efficient parts. Their products, including the 4349789 Diamond Ring Seal, are designed with precision and durability in mind, supporting the performance and longevity of commercial trucks.

Diamond Ring Seal (Part 4349789) Compatibility with Cummins Engines

The Diamond Ring Seal, identified by part number 4349789, is a critical component in ensuring the operational integrity of certain Cummins engines. This seal is designed to provide a reliable barrier against leaks, maintaining the pressure and efficiency required for optimal engine performance.

QSK95 CM2350 K111 and K113 Engines

The Diamond Ring Seal is specifically engineered to fit seamlessly within the QSK95 CM2350 K111 and K113 engines. These engines are part of the Cummins QSK series, known for their robust design and high performance in various industrial applications. The seal’s precision fit ensures that it effectively prevents fluid leakage, which is crucial for maintaining the engine’s operational efficiency and longevity.

The seal’s compatibility with these engines is a testament to Cummins’ commitment to quality and reliability. By ensuring that the Diamond Ring Seal fits perfectly within the QSK95 CM2350 K111 and K113 engines, Cummins guarantees that these engines can operate under demanding conditions without the risk of leaks or performance degradation.

Role of Part 4349789 Diamond Ring Seal in Engine Systems

This Cummins part is an essential component in various engine systems, ensuring the integrity and efficiency of several key connections and assemblies.

Connection Points

The Diamond Ring Seal is utilized at multiple connection points within the engine system to provide a secure and leak-free seal. This includes connections between the raw water outlet and the engine block, where it prevents water ingress and maintains the purity of the engine’s lubrication system.

Raw Water Outlet

At the raw water outlet, the seal ensures that the flow of cooling water is directed efficiently without any leakage. This is vital for maintaining the engine’s temperature within optimal ranges, thereby enhancing performance and longevity.

Mounting Kit

When integrated into a mounting kit, the Diamond Ring Seal plays a role in securing various engine components to the chassis or other structural elements. This ensures that vibrations and movements do not compromise the seals or connections, maintaining the overall stability of the engine system.

Oil Cooler Repair Kit

In an oil cooler repair kit, the seal is used to ensure that the oil cooling process is efficient and leak-free. It helps in maintaining the correct oil temperature, which is essential for the lubrication and protection of moving parts within the engine.

Plumbing

For plumbing applications, the Diamond Ring Seal is employed to create secure connections in the coolant and oil circuits. This prevents any fluid loss and ensures that the engine receives consistent cooling and lubrication.

Oil Cooler Water Service Kit

Within an oil cooler water service kit, the seal is critical for maintaining the integrity of the oil-water interface. This ensures that the oil remains clean and free from water contamination, which could lead to decreased lubrication efficiency.

Tube Kit

In a tube kit, the seal is used to connect various tubes that carry fluids throughout the engine system. This includes fuel lines, coolant passages, and lubrication circuits, ensuring that each connection is secure and leak-free.

Water Pump Kit

Finally, in a water pump kit, the Diamond Ring Seal is used to ensure that the water pump can operate efficiently without any leaks. This is essential for maintaining consistent coolant flow, which is crucial for engine temperature regulation.

Conclusion

The 4349789 Diamond Ring Seal by Cummins is a vital component for the efficient and reliable operation of commercial trucks and Cummins engines. Its robust design, compatibility with various engine systems, and the benefits it offers in terms of sealing performance and durability make it an indispensable part for maintaining the integrity and efficiency of truck and engine systems.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Modern Diesel Technology Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Delmar Cengage Learning, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.