This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The D Ring Seal, part number 4350101, manufactured by Cummins, is a critical component in the maintenance and operation of commercial truck engines. This seal plays a pivotal role in ensuring the integrity of the engine’s sealing system, preventing leaks, and maintaining optimal performance.

Basic Concepts of D Ring Seals

D Ring Seals are mechanical components used to create a seal between two surfaces, typically in rotating or reciprocating applications. They function by maintaining contact with both the shaft and the housing, thereby preventing the escape of fluids and the ingress of contaminants. These seals are commonly applied in various mechanical systems where fluid containment and system integrity are paramount 1.

Purpose of the 4350101 D Ring Seal in Truck Operations

The 4350101 D Ring Seal is designed to withstand the dynamic conditions within commercial truck engines, including high pressures and temperatures, to maintain a consistent seal and prevent fluid leakage. This contributes to the overall performance and longevity of the truck’s mechanical components 2.

Key Features of the 4350101 D Ring Seal

The 4350101 D Ring Seal is characterized by its durable design and material composition, which includes resistance to wear and compatibility with a range of fluids. Its construction ensures longevity under demanding operational conditions, providing a reliable seal that contributes to the efficient functioning of the truck’s engine or transmission system.

Benefits of Using the 4350101 D Ring Seal

Utilizing the 4350101 D Ring Seal offers several advantages, including improved sealing efficiency, reduced leakage, and enhanced performance and reliability of the truck’s mechanical systems. These benefits contribute to lower maintenance costs and increased operational uptime, making it a valuable component for commercial truck fleets.

Installation and Maintenance Guidelines

Proper installation of the 4350101 D Ring Seal involves preparing the sealing surface to ensure a smooth and clean contact area. Following manufacturer-specified torque settings during installation is crucial for achieving the desired seal integrity. Regular maintenance, including inspection for wear and proper lubrication, is recommended to ensure the longevity and optimal performance of the seal 3.

Troubleshooting Common Issues

Common issues associated with D Ring Seals, such as leaks or failure, can often be traced back to installation errors, wear, or compatibility issues with fluids. Troubleshooting steps may include inspecting the seal for damage, ensuring proper installation, and verifying compatibility with the system’s fluids. Replacement of the seal should be considered if significant wear or damage is detected.

Compatibility and Application

The 4350101 D Ring Seal is specifically designed for use within Cummins engines and is compatible with various commercial truck applications. Its application extends across different types of commercial trucks and operational environments, providing a versatile sealing solution for the industry.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its extensive product range and commitment to quality and innovation in engine component manufacturing. The company’s history is marked by a dedication to advancing engine technology and providing reliable, high-performance components for the commercial trucking sector.

Role of Part 4350101 D Ring Seal in Engine Systems

The 4350101 D Ring Seal is integral to the functionality and efficiency of various engine systems. Its application ensures the reliable operation of components by providing necessary sealing and preventing fluid leaks.

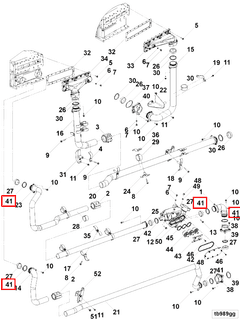

Auxiliary Cooling System

In the auxiliary cooling system, the D Ring Seal is employed to maintain the integrity of coolant flow. It is positioned at critical junctures where coolant tubes connect to the water pump and other components. This seal prevents coolant leakage, ensuring that the cooling system operates efficiently and maintains optimal engine temperature.

Service Kit

When included in a service kit, the D Ring Seal plays a vital role in the maintenance and repair of engine systems. It is often used to replace worn-out seals during routine maintenance, ensuring that all connections remain tight and secure. This helps in prolonging the lifespan of the engine by preventing coolant or oil leaks that could lead to engine damage.

Auxiliary Cooling Tube Kit

Within the auxiliary cooling tube kit, the D Ring Seal is essential for connecting various tubes and fittings. It ensures that the coolant flows smoothly without any interruptions, which is vital for the effective operation of the cooling system. The seal’s durability and reliability are key factors in maintaining the performance of the tube kit.

Water Pump Kit

In the water pump kit, the D Ring Seal is used to secure the connections between the water pump and the coolant passages. This seal is responsible for maintaining the pressure within the cooling system, which is necessary for the proper circulation of coolant. Its accurate fitting and sealing properties are fundamental to the efficient functioning of the water pump.

Conclusion

Overall, the 4350101 D Ring Seal is a fundamental component in ensuring the seamless operation of engine systems by providing reliable seals at critical points. Its role in maintaining the integrity of the engine’s sealing system, preventing leaks, and contributing to the overall performance and longevity of the truck’s mechanical components cannot be overstated.

-

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.