This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4368305 O-Ring Seal is a specialized component designed for use in commercial trucks. It plays a role in maintaining the integrity of various systems within these vehicles. Understanding its purpose and significance is key to ensuring the efficient and reliable operation of trucks in demanding environments.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. In mechanical systems, O-Ring Seals are employed to prevent the leakage of fluids and gases, and to exclude contaminants. They function effectively in both dynamic and static applications, adapting to the movement and pressure changes within the system 1.

Purpose of the Cummins 4368305 O-Ring Seal

The Cummins 4368305 O-Ring Seal is specifically designed to play a role in the sealing mechanisms of commercial trucks. It is associated with various systems or components within the truck, ensuring that fluids and gases remain contained within their designated pathways. This seal contributes to the overall efficiency and reliability of the truck’s operation by maintaining system integrity under varying conditions.

Key Features

The Cummins 4368305 O-Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. Its material composition is designed to withstand the rigors of commercial truck environments, offering durability and resistance to wear. The seal’s design characteristics, including its precise dimensions and elastomeric properties, ensure a tight and reliable seal in challenging conditions.

Benefits

Utilizing the Cummins 4368305 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases are effectively contained. The seal’s durability and reliability in harsh operating conditions help to prolong the service life of the associated systems, reducing the need for frequent replacements and maintenance. This results in enhanced overall reliability and performance of the truck.

Installation Considerations

Proper installation of the Cummins 4368305 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the seal is correctly sized and fitted, avoiding damage during installation, and verifying that the mating surfaces are clean and free of contaminants. Adhering to these practices helps to maintain the integrity of the seal and the systems it protects.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, material degradation, or environmental factors. Troubleshooting steps may include inspecting the seal for signs of wear or damage, checking the mating surfaces for cleanliness and proper fit, and assessing the environmental conditions to which the seal is exposed. Addressing these issues promptly can help to restore system integrity and prevent further complications.

Maintenance Tips

Regular maintenance of O-Ring Seals is important for prolonging their service life and ensuring continued reliable operation. Maintenance tips include periodic inspection for signs of wear or damage, cleaning the mating surfaces as needed, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. These practices contribute to the overall reliability and efficiency of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to quality and customer satisfaction is reflected in its extensive lineup of parts and services designed to meet the demanding needs of commercial trucking 2.

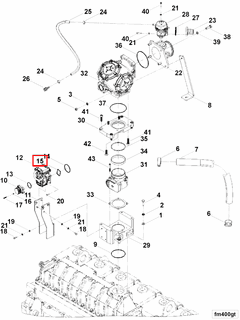

Role of Part 4368305 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 4368305, is integral to the functionality and efficiency of several engine components. In the Fuel Control Module, this seal ensures that the fuel delivery system maintains a consistent and leak-free operation. It secures the connections within the module, preventing any fuel leakage that could compromise engine performance or safety.

Within the broader Module assemblies, the O-Ring Seal plays a significant role in maintaining the integrity of the system. It seals the interfaces between various components, ensuring that fluids and gases remain contained within their designated pathways. This containment is essential for the module’s accurate operation and longevity.

In the Fuel Control system, the O-Ring Seal is positioned to prevent any unwanted mixing of fuel with air or other substances, which could lead to inefficient combustion or potential hazards. Its placement around critical junctions ensures that the fuel control system operates within specified parameters, contributing to overall engine efficiency.

The Pressure Regulator Valve relies on the O-Ring Seal to maintain consistent pressure levels within the fuel system. By sealing the valve’s components, it ensures that pressure is regulated accurately, which is vital for the engine’s performance and fuel economy.

Lastly, in conjunction with the Valve and Pressure Regulator, the O-Ring Seal helps in maintaining the precise pressure required for optimal engine operation. It ensures that the valve functions smoothly without any leakage, which is essential for the regulator to perform its role effectively.

Conclusion

Overall, the Cummins 4368305 O-Ring Seal is a small yet significant component that contributes to the reliable operation of various engine systems by ensuring seals are intact, pressures are consistent, and fluids are contained. Its role in maintaining system integrity under demanding conditions highlights the importance of proper installation, maintenance, and troubleshooting to ensure the efficient and reliable operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.