This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4385749 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty trucks. This Cummins part is specifically engineered to meet the demanding requirements of truck operations.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in various mechanical systems due to their simplicity, effectiveness, and versatility in creating reliable seals across different applications 1.

Purpose of the 4385749 O-Ring Seal in Truck Operations

In the context of commercial trucks, the 4385749 O-Ring Seal plays a specific role within the vehicle’s systems. It is positioned in areas where sealing is required to prevent leaks of fluids such as oil, coolant, or other substances. By ensuring these seals are intact, the O-Ring contributes to the overall efficiency and safety of the truck’s operation. Its placement is critical in maintaining the integrity of the system it is part of, whether in the engine, transmission, or other components 2.

Key Features of the 4385749 O-Ring Seal

The 4385749 O-Ring Seal is characterized by its design and material properties, which are tailored for heavy-duty applications. It is made from materials that offer resistance to high temperatures, pressure, and a variety of chemicals. These features make it particularly suitable for the harsh environments encountered in commercial truck operations, ensuring durability and reliability under demanding conditions 3.

Benefits of Using the 4385749 O-Ring Seal

Utilizing the 4385749 O-Ring Seal in commercial trucks offers several advantages. It provides improved reliability in sealing applications, contributing to the overall performance and longevity of the truck. The seal’s design and material properties ensure it can withstand the rigors of heavy-duty use, offering a cost-effective solution for maintaining system integrity and efficiency 4.

Installation Considerations

Proper installation of the 4385749 O-Ring Seal is key to ensuring its optimal performance and longevity. Guidelines for installation include ensuring the groove is clean and free of debris before placing the O-Ring. Careful handling is advised to avoid damaging the seal, and it should be lubricated with a compatible fluid to facilitate easy insertion and seating. Following these best practices helps in achieving a secure and effective seal 5.

Troubleshooting Common Issues

Common problems with O-Ring Seals in truck applications can include leaks, which may arise from improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps involve inspecting the seal for signs of damage or deformation, checking the groove for cleanliness and proper sizing, and ensuring compatibility with the fluids and operating conditions. Addressing these issues promptly can help maintain the seal’s effectiveness and prevent further complications 6.

Maintenance Tips

Regular maintenance of the 4385749 O-Ring Seal is important for prolonging its service life and maintaining its effectiveness. This includes periodic inspection for signs of wear or damage, and replacement according to the manufacturer’s recommendations or as part of routine maintenance schedules. Keeping the seal and its surrounding areas clean and free of contaminants also contributes to its longevity and performance 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial vehicle industry. Its product range is designed to meet the needs of various applications, from on-highway to off-highway, ensuring reliability, performance, and efficiency in demanding environments 8.

Cummins O-Ring Seal 4385749 Compatibility with QSK95 Engines

The O-Ring Seal 4385749, manufactured by Cummins, is designed to fit seamlessly within the QSK95 engine series. Specifically, this seal is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engine models.

In these engines, the O-Ring Seal 4385749 plays a crucial role in ensuring that various components maintain their integrity and operate efficiently. Its primary function is to provide a reliable seal in areas where components interface, preventing leaks and maintaining system pressures. This seal is essential in high-performance environments where reliability and precision are paramount.

The seal’s design and material composition are tailored to withstand the demanding conditions within these engines, including high temperatures, pressures, and exposure to various fluids. This ensures that the seal remains effective over the engine’s operational life, contributing to overall engine performance and longevity.

By integrating the O-Ring Seal 4385749 into the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, users can expect enhanced sealing capabilities, reduced maintenance needs, and improved operational efficiency 9.

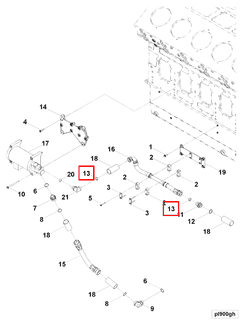

Role of Part 4385749 O-Ring Seal in Engine Systems

The part 4385749 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a specific role in the engine’s operation.

Aid Systems

In aid systems, the O-Ring Seal is used to create a tight seal between components, preventing leaks and ensuring that aid fluids are delivered efficiently to their intended locations. This is particularly important in systems where precise fluid delivery is necessary for optimal engine performance.

Coolant Heater Starting System

Within the coolant heater starting system, the O-Ring Seal is employed to maintain a secure seal around the heater core and associated fittings. This ensures that coolant circulates effectively, providing the necessary warmth to facilitate easier engine starts in cold conditions.

Check Valve

The check valve relies on the O-Ring Seal to prevent backflow of fluids. By ensuring a snug fit between the valve components, the seal maintains the unidirectional flow of fluids, which is essential for the valve’s proper function and the overall efficiency of the system.

Engine Heater

In engine heater applications, the O-Ring Seal is critical for maintaining the integrity of the heater assembly. It prevents coolant leaks, ensuring that the heater can effectively warm the engine block and other components during startup, particularly in colder climates.

Gasket Kit

When used in conjunction with a gasket kit, the O-Ring Seal enhances the sealing capabilities between mating surfaces. This is vital for maintaining pressure and preventing leaks in systems where gaskets are employed, such as in the engine block or cylinder head.

Hose Kit

Within a hose kit, the O-Ring Seal is often used at connection points to ensure a leak-free seal. This is essential for maintaining the integrity of fluid lines, whether they are carrying coolant, fuel, or other essential fluids.

Male Union and Male Union Elbow

For male union and male union elbow fittings, the O-Ring Seal provides a reliable seal that withstands pressure and vibration. This is particularly important in dynamic engine environments where fittings are subject to constant movement and stress.

Primer

In primer systems, the O-Ring Seal ensures that the priming fluid is delivered without leakage. This is important for systems that require precise fluid levels to function correctly, such as fuel priming systems in engines.

Engine Lubricating System

The engine lubricating system benefits from the O-Ring Seal by maintaining the integrity of oil lines and fittings. This ensures that lubricants are delivered efficiently to moving parts, reducing friction and wear.

Tube Connector Tee

Finally, in tube connector tee applications, the O-Ring Seal ensures that the connection points remain leak-free. This is essential for systems where multiple fluid lines converge, such as in complex engine lubrication or cooling systems.

Conclusion

The 4385749 O-Ring Seal by Cummins is a critical component in the maintenance and efficiency of commercial truck engines. Its design and material properties are tailored to withstand the demanding conditions of heavy-duty applications, ensuring durability, reliability, and efficiency. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the performance and longevity of this part. By understanding the role and benefits of the 4385749 O-Ring Seal, truck operators and maintenance professionals can ensure the optimal operation of their vehicles.

-

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5467181, 2023.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Cummins Inc. Company Overview. 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5467181, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.