Introduction to O-Ring Seals

An O-Ring Seal is a mechanical gasket shaped like a torus, essentially a loop or ring with a round cross-section. These seals are indispensable in preventing the leakage of fluids or gases across various applications, including commercial truck engines. By creating a tight seal between two surfaces, O-Ring Seals effectively prevent the passage of substances through the interface, ensuring the integrity of the system they serve 1.

Functionality and Importance of the Cummins 4900441 O-Ring Seal

The Cummins 4900441 O-Ring Seal is meticulously designed for use in commercial truck engines. Its primary function is to ensure that vital fluids, such as oil and coolant, remain contained within the engine’s system. This seal is paramount for maintaining engine efficiency and preventing contamination that could precipitate mechanical failure 2.

How the Cummins 4900441 O-Ring Seal Works

Upon installation, the O-Ring Seal compresses between two surfaces, forming a barrier that staunches the leakage of fluids. The material of the seal must be compatible with the substances it will encounter, such as oils, coolants, and other engine fluids. The seal’s elasticity allows it to conform to the surfaces it seals, ensuring a consistent and reliable barrier. This adaptability is crucial for withstanding the dynamic conditions within an engine 3.

Role of the Cummins 4900441 O-Ring Seal in Truck Operations

In the realm of commercial truck engines, the O-Ring Seal is instrumental in preserving the integrity of the engine’s lubrication and cooling systems. Proper sealing is essential for the engine to operate efficiently and reliably, thereby reducing the risk of breakdowns and costly repairs. The seal’s capacity to endure high temperatures and pressures is vital for the engine’s longevity and performance 4.

Troubleshooting and Maintenance of the Cummins 4900441 O-Ring Seal

Regular inspection and maintenance of the O-Ring Seal are imperative for preventing leaks and ensuring optimal engine performance. Engineers and mechanics should vigilantly check the seal for signs of wear, such as cracks, deformation, or loss of elasticity. If any issues are detected, the seal should be replaced promptly to avert potential engine damage.

Maintenance tips include:

- Conducting regular inspections of the seal for signs of wear or damage.

- Ensuring that the seal is correctly installed and seated in its designated location.

- Employing the correct tools and techniques when replacing the seal to avoid damage.

- Keeping the seal clean and free from contaminants that could impair its performance.

Compatibility and Applications of the Cummins 4900441 O-Ring Seal

The Cummins 4900441 O-Ring Seal is designed to fit seamlessly with several engine models, ensuring a secure seal that prevents leaks and maintains optimal performance. This part is compatible with the A1400 and A1700 engines, where it plays a crucial role in maintaining the integrity of fluid systems by preventing leaks at critical junctures.

In the A2000 and A2300 engines, the O-Ring Seal is equally essential. These engines, known for their robust design and efficiency, rely on this seal to maintain pressure and prevent fluid loss, ensuring that the engine operates smoothly and efficiently.

The design of the O-Ring Seal is tailored to fit the specific requirements of these engines, providing a reliable and durable solution that enhances the overall performance and longevity of the engine. Its compatibility across multiple engine models underscores its versatility and importance in maintaining engine efficiency and reliability.

Role of Part 4900441 O-Ring Seal in Engine Systems

The part 4900441 O-Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall functionality of the engine.

Integration with the Balancer and Engine Balancer

In the context of the balancer and engine balancer, the O-Ring Seal (part 4900441) is utilized to create a tight seal between the balancer and the engine block. This seal is vital for preventing oil leaks, which could otherwise lead to reduced lubrication efficiency and potential damage to the balancer and surrounding components. The seal ensures that the balancer operates within its designed parameters, contributing to the smooth operation of the engine by counteracting vibrations.

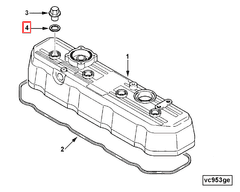

Application in the Engine Cover

When installed in the engine cover, the O-Ring Seal serves to maintain a secure barrier against oil and other fluids. The engine cover, which protects internal components from debris and contaminants, relies on the O-Ring Seal to prevent fluid ingress and egress. This application is particularly important in high-performance engines where maintaining optimal fluid levels is essential for performance and longevity.

Interaction with Valves

In valve applications, the O-Ring Seal is used to ensure a leak-proof connection between the valve stem and the valve cover. This is important for maintaining the correct pressure within the valve system, which directly affects engine performance. The seal helps in preventing oil from entering the combustion chamber, which could lead to fouling of the spark plugs and reduced engine efficiency.

Coordination with Gasket Sets

The O-Ring Seal also works in conjunction with gasket sets to provide an additional layer of sealing. In scenarios where gaskets are used to seal mating surfaces between engine components, the O-Ring Seal can be employed to enhance the seal’s effectiveness. This is particularly useful in areas where gaskets alone may not provide sufficient sealing due to the dynamic nature of engine operation.

General Engine Applications

Across various engine applications, the O-Ring Seal (part 4900441) is a versatile component that ensures the engine operates within its specified parameters. By preventing fluid leaks and maintaining pressure integrity, it contributes to the overall reliability and performance of the engine system. Its role in sealing critical components underscores the importance of proper installation and maintenance to ensure the longevity and efficiency of the engine.

Conclusion

Grasping the role and maintenance of the Cummins 4900441 O-Ring Seal is crucial for engineers, mechanics, truck drivers, and fleet operators. Proper care and attention to this critical component can profoundly impact the performance and longevity of commercial truck engines. By adhering to best practices for inspection and maintenance, professionals can ensure that their engines operate efficiently and reliably, minimizing downtime and reducing repair costs.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.