Introduction

The Cummins Injector Seal 4900464 is a critical component in the fuel injection systems of Cummins engines. It ensures a secure and leak-free connection between the injector and the fuel system, maintaining the integrity of the fuel injection process, which is essential for the efficient operation of heavy-duty trucks 1.

Basic Concepts of Injector Seals

Injector seals serve as barriers between the fuel injector and the fuel system. Their primary function is to prevent fuel leaks and maintain the pressure required for proper fuel atomization. In diesel engines, injector seals are vital for overall performance, ensuring that fuel is delivered efficiently and consistently to the combustion chamber 2.

Role of the 4900464 Injector Seal in Truck Operation

The 4900464 Injector Seal is specifically designed for Cummins engines and plays a significant role in the fuel injection system by providing a reliable seal that prevents fuel leakage. This seal contributes to fuel efficiency by ensuring that fuel is delivered under the correct pressure and in the right quantity. Additionally, it helps maintain engine performance by ensuring that the fuel injection process is consistent and precise 3.

Key Features of the 4900464 Injector Seal

The 4900464 Injector Seal is characterized by its durable material composition, designed to withstand the high pressures and temperatures of the fuel injection system. Its design attributes include a precise fit that ensures a secure connection, and it may feature unique characteristics such as enhanced resistance to wear and corrosion. These features contribute to the seal’s functionality and longevity.

Benefits of Using the 4900464 Injector Seal

The use of the 4900464 Injector Seal offers several advantages. It improves fuel atomization by maintaining the necessary pressure and preventing leaks, leading to more efficient combustion. This can result in reduced emissions as the fuel is burned more completely. Additionally, the seal contributes to enhanced engine longevity by ensuring that the fuel injection system operates within optimal parameters.

Installation and Maintenance Guidelines

Proper installation of the 4900464 Injector Seal involves ensuring that the seal is correctly positioned and that all connections are secure. Maintenance tips include regular inspection for signs of wear or damage, and replacement as necessary to prevent potential issues such as leaks or performance degradation.

Troubleshooting Common Issues

Common problems associated with injector seals include leaks and performance issues. Troubleshooting methods may involve inspecting the seal for damage, ensuring proper installation, and replacing the seal if necessary. Addressing these concerns promptly can help maintain the efficiency and reliability of the fuel injection system.

Performance Enhancements

The 4900464 Injector Seal contributes to overall engine performance by ensuring that fuel is delivered efficiently and consistently. This can lead to improvements in power output, fuel efficiency, and emission reductions, as the engine operates more effectively with a reliable fuel injection system.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a broad product range that includes engines, filtration, power generation, and emission solutions. The company has a strong reputation in the heavy-duty truck industry for producing reliable and high-performance engines. Cummins’ commitment to innovation and quality has made it a preferred choice for many fleet operators and equipment manufacturers.

Cummins Injector Seal Part 4900464 Compatibility

The Cummins Injector Seal part number 4900464 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This seal is crucial for maintaining the integrity of the fuel injection system, preventing leaks, and ensuring efficient fuel delivery.

A1400 and A1700 Engines

The Injector Seal part 4900464 is compatible with both the A1400 and A1700 engines. These engines are known for their robust design and are often used in various industrial applications. The seal fits precisely around the injector, providing a tight seal that prevents fuel from leaking out, which is essential for maintaining the engine’s efficiency and longevity.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines also benefit from the use of the Cummins Injector Seal part 4900464. These engines are typically used in more demanding applications, such as heavy-duty trucks and construction equipment. The seal ensures that the injector operates correctly, maintaining the engine’s performance and reliability under heavy loads.

Grouping for Efficiency

When considering the compatibility of the Injector Seal part 4900464, it is beneficial to group the A1400 and A1700 engines together due to their similar design and application. Likewise, the A2000 and A2300 engines can be grouped together for the same reason. This grouping simplifies the process of ensuring that the correct seal is used for each engine type, enhancing maintenance efficiency and reducing the risk of using an incorrect part.

By using the Cummins Injector Seal part 4900464, operators can ensure that their engines remain in optimal condition, providing reliable performance and extending the life of their equipment.

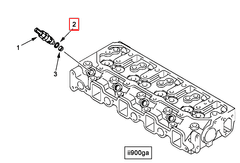

Role of Part 4900464 Injector Seal in Engine Systems

The injector seal, specifically part 4900464, is a critical component in ensuring the efficient and reliable operation of engine systems. Its primary function is to create a secure and leak-free connection between the fuel injector and the engine block. This seal is instrumental in maintaining the integrity of the fuel delivery system, preventing fuel leaks, and ensuring that fuel is delivered at the correct pressure and timing.

When integrated with a compression tester, the injector seal plays a supportive role in diagnosing engine performance. A well-sealed injector ensures that the compression test results are accurate, as any fuel leaks could skew the readings and lead to misdiagnosis. The seal helps maintain consistent cylinder pressure, which is vital for reliable compression test outcomes.

In conjunction with a gasket set, the injector seal complements the gaskets’ role in sealing various engine components. While gaskets seal the interfaces between major engine parts, the injector seal focuses on the fuel injector’s connection point. Together, they create a comprehensive sealing solution that prevents fluid and gas leaks, ensuring the engine operates within optimal parameters.

The relationship between the injector seal and the injector itself is particularly significant. The seal ensures that the injector can perform its function without any fuel escaping into the engine bay. This not only protects the engine from potential fire hazards but also ensures that the injector delivers fuel efficiently, contributing to better fuel economy and reduced emissions.

Conclusion

In summary, the 4900464 Injector Seal is a vital component that works in harmony with other engine parts to ensure safety, efficiency, and optimal performance. Its role in maintaining the integrity of the fuel injection system is crucial for the reliable operation of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.