This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

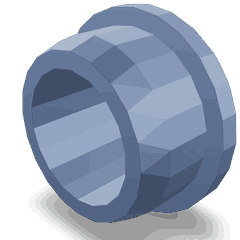

The Cummins 4905643 Ferrule Seal is a component designed to ensure secure and leak-free connections in the hydraulic and fuel systems of commercial trucks. Ferrule seals play a significant role in maintaining the integrity of these systems by providing a reliable seal at connection points. This overview will explore the function and importance of the 4905643 Ferrule Seal, along with its role in the efficient operation of commercial vehicles.

Basic Concepts of Ferrule Seals

A ferrule seal is a type of fitting used to connect hoses or pipes in hydraulic and fuel systems. It functions by compressing a seal around the hose or pipe, creating a tight connection that prevents leaks. Ferrule seals are typically made from materials such as stainless steel, brass, or copper, chosen for their durability, resistance to corrosion, and ability to withstand high pressures 1. The material selection is critical for ensuring the seal’s performance and longevity in demanding environments.

Purpose of the 4905643 Ferrule Seal

The 4905643 Ferrule Seal is specifically designed to facilitate secure and leak-free connections in the hydraulic and fuel lines of commercial trucks. By ensuring a tight seal, it plays a role in maintaining system pressure, preventing fluid leaks, and contributing to the overall efficiency and safety of the vehicle’s operation. Its design is tailored to meet the rigorous demands of commercial truck applications, ensuring reliable performance under various operating conditions 2.

Key Features

The 4905643 Ferrule Seal features a design that includes a ferrule, a seal, and a nut. The ferrule is crimped onto the hose or pipe, while the seal is compressed between the ferrule and the nut, creating a secure connection. The seal is typically made from materials like PTFE or Viton, known for their excellent resistance to chemicals and high temperatures. These materials contribute to the seal’s durability and performance in harsh environments 3.

Benefits of Using the 4905643 Ferrule Seal

Utilizing the 4905643 Ferrule Seal offers several advantages, including improved system reliability through secure connections, reduced maintenance needs due to its durable construction, and enhanced safety by preventing leaks that could lead to system failures or environmental hazards. Its design also allows for easy installation and replacement, minimizing downtime during maintenance procedures.

Installation Process

Installing the 4905643 Ferrule Seal requires careful preparation and the use of appropriate tools. The process involves cutting the hose to the correct length, inserting it into the ferrule, and then crimping the ferrule onto the hose using a crimping tool. The assembly is then screwed onto the fitting, ensuring the seal is properly compressed. Following manufacturer guidelines for torque specifications and installation procedures is important to ensure a secure fit.

Troubleshooting Common Issues

Common issues with ferrule seals include leaks and improper seating. Troubleshooting these problems may involve inspecting the seal for damage, ensuring the ferrule is properly crimped, and verifying that the seal is correctly compressed between the ferrule and the nut. Addressing these issues promptly can help maintain system integrity and prevent further complications.

Maintenance Tips

Regular maintenance of the 4905643 Ferrule Seal includes inspecting the seal for signs of wear or damage, cleaning the fitting and seal surfaces to remove any contaminants, and replacing the seal as needed. Adhering to a maintenance schedule can help prolong the life of the seal and ensure the continued reliability of the hydraulic and fuel systems.

Compatibility and Applications

The 4905643 Ferrule Seal is designed for use in commercial truck systems, where it is compatible with a range of hydraulic and fuel line applications. Its design ensures compatibility with various hose and pipe sizes, making it a versatile component for maintaining system integrity in commercial vehicles.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins is renowned for its commitment to providing reliable and efficient solutions for the commercial truck industry. The company’s extensive product range and reputation for excellence underscore its position as a leader in automotive component manufacturing.

Cummins Engine Compatibility with Ferrule Seal Part 4905643

The Ferrule Seal part 4905643, manufactured by Cummins, is a critical component in the engine systems of several Cummins engine models. This part is designed to ensure a secure and leak-free connection between various engine parts, enhancing the overall performance and reliability of the engine.

ISB6.7 CM2350 B101 and QST30 CM2350 T101

The ISB6.7 CM2350 B101 and QST30 CM2350 T101 engines both utilize the Ferrule Seal part 4905643. This part is essential in these engines for maintaining the integrity of the fuel and lubrication systems, ensuring that there are no leaks or pressure drops that could affect engine performance.

L8.9 CM2670 L134C

The L8.9 CM2670 L134C engine also incorporates the Ferrule Seal part 4905643. In this engine, the seal plays a crucial role in the high-pressure fuel system, providing a reliable seal that prevents fuel from leaking out, which is vital for maintaining optimal engine efficiency and safety.

QSK50 CM2150 K107 and QSK50 CM2150 MCRS

Both the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines feature the Ferrule Seal part 4905643. This part is integral to these engines’ fuel systems, ensuring that the seals between the fuel lines and the engine are tight and secure, which is critical for the high-pressure operations typical of these models.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines also benefit from the Ferrule Seal part 4905643. In these engines, the seal is used in various high-pressure systems, ensuring that the connections remain leak-proof and that the engine operates at peak efficiency.

QSK60G

The QSK60G engine utilizes the Ferrule Seal part 4905643 in its critical systems. This part is essential for maintaining the seal integrity in the high-pressure fuel and lubrication systems, which is crucial for the engine’s performance and longevity.

Role of Part 4905643 Ferrule Seal in Engine Systems

The part 4905643 Ferrule Seal is integral to maintaining the integrity and performance of various engine systems. It ensures secure and leak-free connections in several key components.

Fuel System

In the fuel supply system, the Ferrule Seal is employed at the junction of the fuel supply tube and the flexible hose. This seal prevents fuel leaks, ensuring consistent fuel delivery to the engine. It also maintains the required pressure within the fuel lines, which is essential for optimal engine performance.

Engine Control Module (ECM)

The Engine Control Module relies on accurate data from various sensors to manage engine operations. The Ferrule Seal is used in the pressure sensing tube connections to the ECM. This ensures that pressure readings are precise and unaffected by leaks, allowing the ECM to make informed adjustments to fuel injection and ignition timing.

Turbocharger Systems

Turbochargers require robust sealing solutions to handle high-pressure environments. The Ferrule Seal is utilized in both the turbocharger coolant supply tube and the turbocharger oil supply tube. These seals prevent coolant and oil leaks, which are vital for maintaining turbocharger efficiency and longevity.

Auxiliary Cooling System

In the auxiliary cooling system, the Ferrule Seal is critical at the connections of the water transfer tube. This ensures that coolant flows smoothly without any loss, helping to maintain optimal engine temperatures and prevent overheating.

Engine Monitoring and Plumbing

For engine monitoring systems, the Ferrule Seal is used in various plumbing connections to ensure that all fluid lines—whether for fuel, coolant, or oil—remain sealed. This is important for accurate monitoring and maintaining the overall health of the engine.

Vent Tubes

In vent tubes, the Ferrule Seal plays a role in maintaining pressure balance within the engine compartments. It ensures that any vented gases or fluids do not escape, which could otherwise lead to pressure imbalances and reduced engine performance.

Conclusion

In summary, the part 4905643 Ferrule Seal is a versatile component that enhances the reliability and performance of multiple engine systems by ensuring secure, leak-free connections.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.