This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4919908 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the engine and component manufacturing industry, produces this O-Ring Seal to meet the demanding requirements of heavy-duty applications. The seal plays a role in ensuring the integrity of various systems within commercial trucks, contributing to their overall efficiency and reliability 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in creating seals in a variety of applications 2.

Purpose of the 4919908 O-Ring Seal in Truck Operations

This Cummins part is specifically designed to play a role in the operation of commercial trucks. It is applied in areas where sealing is required to maintain system integrity, such as in fuel systems, hydraulic systems, and engine components. By providing a reliable seal, it supports the efficient operation of these systems, helping to ensure that trucks perform optimally under various conditions.

Key Features of the 4919908 O-Ring Seal

This part is characterized by its design and material properties, which make it suitable for heavy-duty truck applications. It is made from materials that offer durability and resistance to a range of fluids and operational temperatures. These features allow it to withstand the rigors of commercial truck use, providing a reliable seal in challenging environments.

Benefits of Using the 4919908 O-Ring Seal

Utilizing this part in truck operations offers several advantages. It contributes to improved system reliability by ensuring that seals remain intact under pressure and in the presence of various fluids. This can lead to reduced maintenance needs, as the seal is designed to withstand the demands of heavy-duty use. Additionally, its performance in demanding conditions helps to enhance the overall efficiency and longevity of the truck’s systems.

Troubleshooting Common Issues with O-Ring Seals

Identifying and addressing common problems associated with O-Ring Seals, such as leaks, wear, and failure symptoms, is important for maintaining system integrity. Effective troubleshooting involves inspecting the seal for signs of damage, ensuring proper installation, and replacing the seal when necessary. These steps help to prevent issues that could lead to system failure or reduced performance.

Maintenance Tips for O-Ring Seals

To ensure the longevity and optimal performance of O-Ring Seals, regular maintenance is recommended. This includes routine inspections to check for wear or damage, following manufacturer guidelines for replacement, and adhering to best practices during installation. Proper maintenance helps to preserve the seal’s effectiveness, contributing to the overall reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial vehicle industry, known for its history of innovation and commitment to quality in engine and component manufacturing. The company offers a wide range of products designed to meet the needs of various industries, with a focus on delivering reliable and efficient solutions. Cummins’ reputation is built on its dedication to advancing technology and providing customers with products that enhance their operations.

Cummins O-Ring Seal Part 4919908 Compatibility with Engine Models

The Cummins O-Ring Seal part number 4919908 is a component designed to ensure the integrity of various engine systems. This seal is engineered to fit seamlessly within the engine architecture of specific Cummins models, providing a reliable barrier against leaks and maintaining system pressure.

K19 Engine

In the K19 engine, the O-Ring Seal part 4919908 is integral to the fuel injection system. It ensures that the high-pressure fuel lines remain sealed, preventing any fuel leakage that could compromise engine performance or safety. This seal is typically found in the fuel pump or injector connections, where it plays a crucial role in maintaining the system’s efficiency.

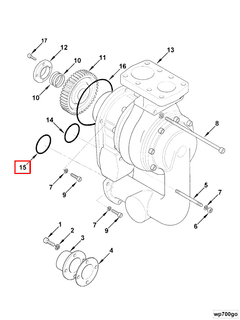

QSV81G and QSV91G Engines

For the QSV81G and QSV91G engines, the O-Ring Seal part 4919908 is utilized in several key areas. In these engines, the seal is commonly used in the turbocharger system, where it helps to maintain the integrity of the air intake and exhaust systems. This ensures that the turbocharger operates efficiently, contributing to the engine’s overall performance and longevity.

Additionally, the seal is also employed in the cooling system, where it prevents coolant leaks that could lead to overheating and potential engine damage. Its placement in these critical areas underscores the importance of the O-Ring Seal in maintaining the operational integrity of the QSV81G and QSV91G engines.

By ensuring a tight seal in these systems, the part 4919908 helps to maintain the efficiency and reliability of the engines, contributing to their overall performance and durability.

Role of Part 4919908 O-Ring Seal in Engine Systems

The 4919908 O-Ring Seal is an essential component in various engine systems, particularly those involving fluid dynamics and the prevention of leaks. Its application spans across several key components, ensuring the integrity and efficiency of the systems they are part of.

Sea Water Pump Systems

In sea water pump systems, the 4919908 O-Ring Seal is utilized to create a tight seal between the pump housing and the impeller or other moving parts. This seal is vital for maintaining the pressure within the pump, ensuring that sea water is effectively circulated through the engine’s cooling system. The seal prevents any leakage of sea water, which could otherwise lead to corrosion or contamination of other engine components.

Raw Water Pump Systems

Similarly, in raw water pump systems, the O-Ring Seal plays a significant role. It ensures that raw water, which is often a mixture of fresh and sea water, is pumped efficiently without any loss. The seal is positioned at critical junctions within the pump, such as between the pump body and the impeller shaft. This placement is essential for maintaining the pump’s operational efficiency and longevity.

Water Pump Systems

For general water pump systems, the 4919908 O-Ring Seal is employed to seal the connections between the pump housing and the shaft or other rotating components. This application is fundamental in preventing water leakage, which could reduce the pump’s effectiveness and lead to potential damage to the engine or surrounding components.

Kit 2-Sea Water Pump and Kit On-Board Spares

In the context of kit 2-sea water pump and kit on-board spares, the O-Ring Seal is often included as a standard component. Its role in these kits is to provide a reliable seal for the pump’s moving parts, ensuring that the pump functions correctly when installed or as a replacement part. The inclusion of the O-Ring Seal in these kits underscores its importance in maintaining the pump’s performance and durability.

Overall Importance

Across all these applications, the 4919908 O-Ring Seal’s role is to ensure that the pump systems operate efficiently and without leaks. Its proper installation and maintenance are key to the overall performance and reliability of the engine systems it supports.

Conclusion

The 4919908 O-Ring Seal by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and material properties ensure durability and reliability in heavy-duty applications, contributing to the efficiency and longevity of the systems it supports. Regular maintenance and proper installation of this part are essential for the optimal performance of truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.