This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4927985 O-Ring Seal is integral to the fluid systems of commercial trucks, ensuring leak prevention and maintaining system pressure for efficient vehicle operation. Understanding its purpose and significance is key to maintaining truck performance and reliability.

Basic Concepts of O-Ring Seals

An O-Ring Seal, a circular cross-section gasket, creates a seal between parts by being compressed within a groove, preventing fluid or gas escape. Its simplicity, effectiveness, and versatility make it widely used in mechanical systems 1.

Purpose of the 4927985 O-Ring Seal in Truck Operation

This Cummins part ensures the sealing of fluid passages within the engine and other systems, typically placed in grooves where surfaces meet, such as in fuel injectors or oil passages. It maintains system integrity by preventing leaks, which could lead to efficiency loss or engine damage 2.

Key Features of the 4927985 O-Ring Seal

Designed from materials resistant to a wide range of temperatures and chemical environments, this part offers durability and reliability. Its elasticity allows it to conform to surfaces, providing a tight seal even under pressure 3.

Benefits of Using the 4927985 O-Ring Seal

Improved sealing efficiency contributes to the truck’s overall performance. Its durability ensures long-term reliability, reducing the need for frequent replacements. Resistance to environmental factors enhances its suitability for commercial trucks.

Installation and Maintenance

Proper installation involves ensuring the groove is clean before placing the seal. Using appropriate tools aids in proper seating without damage. Maintenance tips include regular inspection for wear or damage and timely replacement.

Troubleshooting Common Issues

Common problems like leaks or failures can be traced to improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps include inspecting the seal for damage, ensuring groove cleanliness, and verifying compatibility with system fluids and conditions.

Cummins: A Brief Overview

Cummins Inc., a global power leader, designs, manufactures, and distributes engines, filtration, and power generation products. Known for innovation and quality, Cummins’ 4927985 O-Ring Seal reflects the company’s commitment to quality and performance.

Cummins Engine O-Ring Seal 4927985 Compatibility

The 4927985, manufactured by Cummins, is designed for various Cummins engine models, ensuring no leaks or unwanted fluid movement. Below is its compatibility with specified engine models.

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM850 MCRS

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

QSK60 Series

- QSK60 CM850 MCRS

Role of Part 4927985 O-Ring Seal in Engine Systems

In engine systems, the 4927985 O-Ring Seal ensures the integrity and efficiency of various components.

Electronic Fuel Control Kit

In the electronic fuel control kit, the O-Ring Seal creates a tight seal between fuel injectors and the fuel rail, maintaining precise fuel delivery and consistent fuel pressure.

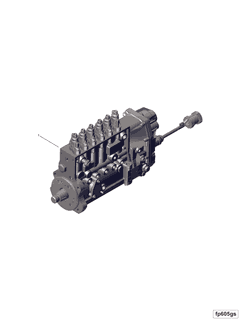

Fuel Injection Pump

In the fuel injection pump, the 4927985 O-Ring Seal prevents fuel leakage at various connection points, ensuring correct fuel pressure delivery to injectors.

Fuel Pump

For the fuel pump, the O-Ring Seal prevents fuel escape at connections between the pump housing and fuel lines, protecting electrical components from fuel contamination.

General Pump Applications

In general pump applications, the 4927985 O-Ring Seal ensures efficient pump operation without leaks, maintaining fluid pressure and purity essential for engine component longevity and performance.

Conclusion

The 4927985 O-Ring Seal plays a significant role in maintaining the efficiency and reliability of engine systems by ensuring secure and leak-free fluid connections.

-

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.