This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4947922 O-Ring Sealing Gasket is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This gasket is engineered for various truck systems, ensuring reliable performance and efficiency. Cummins is recognized for its high-quality parts and extensive product range tailored for commercial vehicles.

Basic Concepts of O-Ring Sealing Gaskets

O-Ring Sealing Gaskets are circular rings, typically made from elastomers, that create seals in mechanical systems. They function by being compressed between two or more mating surfaces, forming a barrier that prevents the leakage of fluids or gases. The effectiveness of an O-Ring Sealing Gasket depends on its material properties, the design of the groove it fits into, and the environmental conditions it operates under 1.

Purpose of the 4947922 O-Ring Sealing Gasket

This Cummins part plays a specific role in the operation of commercial trucks. It is utilized in systems where sealing is required to maintain the integrity of fluid or gas pathways. This includes applications in the engine, transmission, and other critical components where leaks could lead to performance issues or damage. By ensuring a tight seal, this gasket helps maintain system efficiency and reliability 2.

Key Features

The 4947922 O-Ring Sealing Gasket boasts several key features that enhance its performance. It is constructed from high-quality elastomer materials, chosen for their durability and resistance to various operating conditions. The design specifications of this gasket ensure a precise fit within its designated groove, maximizing sealing effectiveness. Additionally, it may include unique attributes such as anti-extrusion properties, which further improve its reliability in demanding environments 3.

Benefits

Using the 4947922 O-Ring Sealing Gasket offers several benefits. Its design contributes to improved sealing efficiency, reducing the risk of leaks and maintaining system performance. The durability of the materials used ensures a longer service life, minimizing the need for frequent replacements. Furthermore, the reliable performance of this gasket can contribute to cost-effectiveness by preventing potential damage caused by leaks and reducing maintenance requirements 4.

Installation Process

Proper installation of the 4947922 O-Ring Sealing Gasket is crucial for its effectiveness. The process involves cleaning the mating surfaces to ensure a smooth and debris-free contact area. The gasket should be lubricated slightly to facilitate insertion into the groove without damage. It is important to follow the manufacturer’s guidelines for torque specifications when assembling the components to avoid over-tightening, which could damage the gasket or the surfaces it seals.

Troubleshooting Common Issues

Common issues with O-Ring Sealing Gaskets include leaks, which can arise from improper installation, damage to the gasket, or degradation over time. Troubleshooting steps include inspecting the gasket for signs of wear or damage, ensuring the mating surfaces are clean and undamaged, and verifying that the installation was performed correctly. If a leak persists, replacing the gasket with a new one may be necessary.

Maintenance Tips

Regular maintenance of the 4947922 O-Ring Sealing Gasket is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, damage, or deformation. Replacement guidelines should be followed based on the manufacturer’s recommendations or if any issues are detected during inspections. Keeping the mating surfaces clean and free of contaminants also contributes to the gasket’s effectiveness.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its innovative and high-quality products. With a history of excellence and a strong reputation, Cummins offers a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles. Their commitment to quality and customer satisfaction has made them a preferred choice among fleet operators and maintenance professionals.

Cummins O-Ring Sealing Gasket Part 4947922 Compatibility

The Cummins O-Ring Sealing Gasket part number 4947922 is designed to fit seamlessly with several engine models, ensuring optimal sealing and performance. This gasket is engineered to provide a reliable seal in various applications, enhancing the overall efficiency and longevity of the engines.

B3.3 Engines

The B3.3 engine series benefits from the precision and durability of the 4947922 gasket. This part is crucial in maintaining the integrity of the engine’s sealing system, preventing leaks and ensuring that the engine operates at peak performance.

QSB3.3 CM2150 and QSB3.3 CM2250 EC Engines

The QSB3.3 CM2150 and QSB3.3 CM2250 EC engines also utilize the 4947922 gasket. This gasket is specifically designed to fit the unique sealing requirements of these models, providing a robust barrier against fluid and gas leaks. Its compatibility with these engines ensures that the sealing system remains intact, contributing to the engines’ reliability and efficiency.

By integrating the 4947922 gasket into these engines, users can expect enhanced sealing performance, reduced maintenance needs, and improved operational efficiency. This gasket is a critical component in maintaining the integrity of the engine’s sealing system, ensuring that the engines perform optimally under various conditions.

Role of Part 4947922 O-Ring Sealing Gasket in Engine Systems

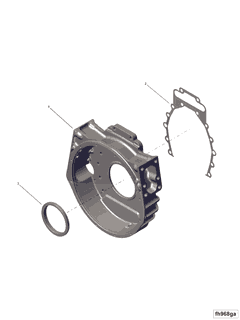

Housing Integration

The part 4947922 O-Ring Sealing Gasket is instrumental in ensuring a secure and leak-proof seal within the housing of engine systems. When installed, it fits snugly into the grooves or designated areas of the housing, creating a barrier that prevents the escape of fluids or gases. This seal is particularly important in environments where the housing encases moving parts or fluid pathways, such as oil or coolant passages. The gasket’s flexibility allows it to conform to any minor imperfections in the housing surface, ensuring a consistent seal across the entire contact area.

Flywheel Assembly

In the context of the flywheel, the part 4947922 O-Ring Sealing Gasket plays a significant role in maintaining the integrity of the seal between the flywheel and its mating surfaces. The flywheel, a key component in the engine’s power transmission, often interfaces with other parts such as the pressure plate in manual transmissions. The O-Ring Sealing Gasket is positioned to prevent any leakage of fluids that might otherwise seep into the clutch assembly, which could lead to contamination and reduced performance. Its placement is typically around the outer edge of the flywheel where it meets the housing or other components, ensuring that the rotational forces do not compromise the seal.

The gasket’s material is chosen for its durability under high temperatures and pressures, making it well-suited for the demanding environment of the flywheel assembly. Its role is to provide a reliable seal that withstands the cyclic stresses induced by engine operation, thereby contributing to the overall efficiency and longevity of the engine system.

Conclusion

The 4947922 O-Ring Sealing Gasket by Cummins is a vital component in the maintenance and efficiency of commercial truck engines. Its design, material quality, and precise fit ensure reliable sealing across various applications, contributing to the overall performance and longevity of the engines it serves. Proper installation, regular maintenance, and understanding its role within engine systems are key to maximizing the benefits of this Cummins part.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.