This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4947924 O-Ring Seal is a component designed to ensure the integrity of seals within heavy-duty truck systems. Its role is significant in maintaining the operational efficiency and reliability of these vehicles. Understanding its function and importance can aid in the effective maintenance and operation of heavy-duty trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, which allows it to form a tight seal against the mating surface. O-Ring Seals are widely used in various mechanical systems to prevent leaks of fluids and gases, ensuring the system operates efficiently 1.

Purpose of the Cummins 4947924 O-Ring Seal

This Cummins part plays a specific role in the operation of heavy-duty trucks. It is utilized in areas where fluid or gas sealing is required to maintain system pressure and prevent leaks. This seal supports various systems within the truck, contributing to its overall performance and reliability.

Key Features

This part is characterized by its material composition, which is typically made from durable elastomers to withstand harsh operating conditions. Its design ensures a snug fit within the designated grooves, enhancing its sealing capabilities. These features contribute to the seal’s performance and reliability in demanding environments.

Benefits

Utilizing the Cummins 4947924 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring tight seals, which can lead to reduced maintenance needs. Additionally, its reliable performance enhances the overall efficiency and durability of the truck’s systems 2.

Installation Considerations

Proper installation of this part is crucial for its optimal performance. Best practices include ensuring the groove is clean and free of debris before installation, using the correct amount of lubrication to facilitate seating, and avoiding over-compression, which can damage the seal.

Troubleshooting Common Issues

Common problems with O-Ring Seals include leaks, which can be caused by improper installation, wear and tear, or incompatibility with the fluid or gas being sealed. Troubleshooting involves inspecting the seal for damage, ensuring it is correctly seated, and verifying compatibility with the system’s requirements.

Maintenance Tips

Regular maintenance practices can prolong the life of the Cummins 4947924 O-Ring Seal. This includes periodic inspection for signs of wear or damage, cleaning the seal and its groove to remove contaminants, and replacing the seal as part of routine maintenance schedules to prevent unexpected failures.

Compatibility and Application

The Cummins 4947924 O-Ring Seal is designed for use in specific applications within heavy-duty truck environments. Its compatibility with various systems ensures it can be effectively utilized across different models and configurations, contributing to the vehicle’s operational integrity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to quality and innovation, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations.

Cummins O-Ring Seal 4947924 Compatibility with Engine Models

The Cummins O-Ring Seal part number 4947924 is designed to fit seamlessly within the specified engine models, ensuring optimal performance and reliability. This seal is integral to maintaining the integrity of various engine components, preventing leaks, and ensuring efficient operation.

B3.3 Engines

The B3.3 engine series benefits from the precision engineering of the 4947924 O-Ring Seal. This seal is crucial in maintaining the seal between moving parts, ensuring that the engine operates smoothly without any unwanted leakage.

QSB3.3 CM2150 and QSB3.3 CM2250 EC Engines

For the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines, the 4947924 O-Ring Seal plays a vital role in maintaining the seal integrity of critical components. These engines, known for their robust performance, rely on this seal to prevent leaks and ensure that the engine maintains its efficiency and longevity. The seal’s compatibility with these models ensures that the engines can operate under various conditions without compromising performance.

Role of Part 4947924 O-Ring Seal in Engine Systems

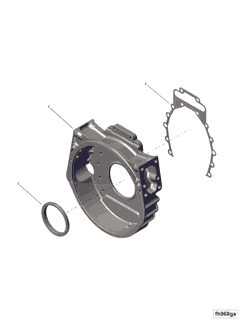

Housing Integration

The 4947924 O-Ring Seal is instrumental in ensuring the integrity of the housing within engine systems. By fitting snugly into the grooves of the housing, it creates a tight seal that prevents fluid leakage. This seal is particularly important in systems where fluid dynamics play a significant role, such as hydraulic or lubrication systems. The O-Ring’s elasticity allows it to conform to the irregularities of the housing surface, maintaining a consistent seal under varying operational conditions.

Flywheel Application

In the context of the flywheel, the 4947924 O-Ring Seal serves to isolate different fluid compartments within the engine. It is often placed in the interface between the flywheel and the housing to prevent the ingress of contaminants and the egress of lubricants. This application is vital for maintaining the efficiency and longevity of the flywheel, as it ensures that the lubricants remain where they are needed most, reducing friction and wear on moving parts. The O-Ring’s durability under high rotational speeds and temperatures makes it an ideal component for this demanding environment 3.

Conclusion

The Cummins 4947924 O-Ring Seal is a critical component in the maintenance and operation of heavy-duty trucks. Its role in ensuring the integrity of seals within various systems contributes to the overall efficiency and reliability of these vehicles. Proper installation, maintenance, and understanding of its application are essential for maximizing the performance and longevity of the truck’s systems.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines, Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.