This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4978005 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and engines known for their reliability and performance. This Cummins part is integral to maintaining the efficiency and functionality of various systems within commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals play a role in preventing leaks by filling the gap between mating surfaces. They operate effectively in both dynamic and static applications, adapting to the movement and pressure changes within the system to maintain a consistent seal 1.

Purpose of the 4978005 O-Ring Seal in Truck Operations

Within the operational systems of a commercial truck, the 4978005 O-Ring Seal serves a specific function. It is positioned in areas where sealing is required to prevent fluid or gas leakage, ensuring the system operates efficiently. Its placement is critical in maintaining the integrity of the system it is part of, contributing to the overall performance and reliability of the truck 2.

Key Features of the 4978005 O-Ring Seal

The 4978005 O-Ring Seal is characterized by its material composition, dimensions, and design. Made from a durable elastomer, it is designed to withstand the operational stresses and environmental conditions encountered in commercial truck applications. Its specific dimensions ensure a precise fit, while its design enhances its sealing capabilities under various conditions.

Benefits of Using the 4978005 O-Ring Seal

Utilizing the 4978005 O-Ring Seal offers several advantages. It provides improved sealing efficiency, contributing to the prevention of leaks and the maintenance of system pressure. Its durability ensures long-term performance, even under demanding conditions. Additionally, it exhibits resistance to a range of environmental factors, enhancing its reliability in diverse operational scenarios 3.

Installation and Maintenance Guidelines

Proper installation of the 4978005 O-Ring Seal involves preparing the sealing surfaces to ensure a clean and smooth contact area. Following manufacturer-specified torque settings during installation helps maintain the integrity of the seal. Regular maintenance, including inspection for wear and damage, ensures the longevity and optimal performance of the O-Ring Seal.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Diagnosing these problems involves a thorough inspection of the seal and its surrounding components. Resolving issues may require reinstallation of the seal or addressing external factors affecting its performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial vehicle industry. Its product range includes engines and components for trucks, buses, construction equipment, and more, serving a wide array of industries worldwide.

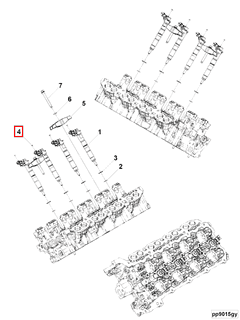

Role of 4978005 O-Ring Seal in Engine Components

The 4978005 O-Ring Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity.

Camshaft

In the camshaft assembly, the O-Ring Seal is utilized to prevent oil leakage between the camshaft and the engine block. This seal ensures that lubrication is maintained without any loss, which is vital for the smooth operation of the camshaft and its associated components.

Front Crankshaft Seal Kit

Within the front crankshaft seal kit, the O-Ring Seal plays a significant role in sealing the front of the crankshaft. This prevents oil from escaping and contaminants from entering, which is essential for the crankshaft’s durability and the overall engine’s reliability.

Injector and Injector Kit

For the injector and injector kit, the O-Ring Seal is employed to create a tight seal around the injector body where it meets the engine block or cylinder head. This ensures that fuel delivery is precise and that there are no leaks, which is important for engine performance and fuel efficiency.

Long Block Kit

In a long block kit, which includes the engine block, crankshaft, pistons, and other core components, the O-Ring Seal is used in various locations to ensure all moving parts are properly sealed. This is important for maintaining compression and preventing oil and fuel leaks within the engine.

Performance Parts

When it comes to performance parts, the O-Ring Seal is often used to enhance the sealing capabilities of high-stress areas. This is particularly important in modified engines where increased power and performance can lead to higher pressures and temperatures.

Service Kit

In a service kit, the O-Ring Seal is a common component used to replace worn or damaged seals during routine maintenance. This helps in restoring the engine’s efficiency and preventing potential issues that could arise from compromised seals.

Upper Engine Gasket Kit

The upper engine gasket kit often includes O-Ring Seals to ensure that all connections between the upper engine components, such as the cylinder head and intake manifold, are properly sealed. This is vital for maintaining the engine’s vacuum integrity and overall performance.

Conclusion

This comprehensive overview of the 4978005 O-Ring Seal by Cummins provides insights into its function, benefits, and application within commercial trucks, underscoring the importance of proper installation and maintenance for optimal performance. The 4978005 plays a critical role in the ISV engines, ensuring a tight seal in various engine applications and contributing to the engine’s performance and longevity. Its application across different engine components highlights its versatility and importance in maintaining the integrity and efficiency of the engine systems.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Hu, H., Baseley, S.J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.