This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5259924 O-Ring Seal is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at enhancing the performance and reliability of trucks. This part is specifically engineered to meet the demanding requirements of truck operations.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a mechanical gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in various mechanical systems due to their simplicity, effectiveness, and versatility in creating reliable seals in different applications 1.

Purpose of the 5259924 O-Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks. It is utilized in various systems where sealing is required to maintain system integrity and efficiency. This includes applications in fuel systems, hydraulic systems, and other areas where fluid or gas containment is necessary. The seal ensures that these systems operate without leaks, contributing to the overall performance and reliability of the truck 2.

Key Features of the 5259924 O-Ring Seal

The 5259924 O-Ring Seal is characterized by its design and material properties. It is made from materials that offer durability and resistance to a range of chemicals and temperatures, ensuring it can withstand the harsh conditions encountered in truck operations. Its design allows for a snug fit within the systems it is intended for, providing an effective seal that contributes to the efficient operation of the truck.

Benefits of Using the 5259924 O-Ring Seal

Utilizing this part in truck systems offers several advantages. It contributes to improved system efficiency by ensuring that fluids or gases are contained within the system, reducing the risk of leaks. This can lead to reduced maintenance needs, as the seal helps prevent issues that might arise from leaks. Additionally, the reliability of the seal enhances the overall performance and dependability of the truck 3.

Installation and Maintenance Guidelines

Proper installation of the 5259924 O-Ring Seal is crucial for its effective operation. This involves preparing the mating surfaces to ensure a clean and smooth fit for the seal. Torque specifications should be followed to ensure the seal is properly compressed within its groove. Regular maintenance, including inspection for wear or damage, is recommended to ensure the longevity and optimal performance of the seal.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Troubleshooting these issues involves checking the seal for proper fit and condition, ensuring that mating surfaces are clean and free of debris, and verifying that the seal is compatible with the fluids or gases it is intended to contain. Addressing these factors can help resolve common problems associated with O-Ring Seals.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and innovation. The company has a long history of producing reliable and high-performance components for trucks, including the 5259924 O-Ring Seal. Cummins’ reputation is built on its dedication to enhancing the efficiency, reliability, and performance of commercial trucks through its products.

Cummins Engine O-Ring Seal Part 5259924

The O-Ring Seal part 5259924, manufactured by Cummins, is a critical component designed to ensure the integrity and efficiency of various engine systems. This seal is engineered to fit seamlessly within a range of Cummins engines, providing a reliable barrier against leaks and maintaining system pressure. Below is a detailed description of the engines with which this O-Ring Seal is compatible.

Compatible Engines

-

B Series Engines

- B4.5 CM2350 B135B

- B6.7 CM2350 B135B

-

D Series Engines

- D4.0 CM2620 D103B

-

F Series Engines

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

-

ISB Series Engines

- ISB4.5 CM2350 B104

-

ISF Series Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

-

ISG Series Engines

- ISG12 G CMOH6.0 G111

-

QSF Series Engines

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

-

R Series Engines

- R2.8 CM2220 R101B

Each of these engines, despite their differences, relies on the O-Ring Seal part 5259924 to maintain operational efficiency and prevent leaks. This seal is designed to withstand the specific pressures and environments within these engines, ensuring long-lasting performance and reliability.

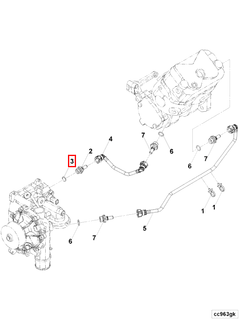

Role of Part 5259924 O-Ring Seal in Engine Systems

The part 5259924 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Here’s how it integrates with the provided components:

Compressor Coolant System

In the compressor coolant arrangement, the O-Ring Seal is used at connection points to prevent coolant leaks. This ensures that the compressor operates within optimal temperature ranges, enhancing performance and longevity.

Auxiliary Cooling Plumbing

Within the auxiliary cooling plumbing, the O-Ring Seal is essential at joints and connections. It maintains the seal integrity, allowing the system to efficiently manage heat dissipation away from critical engine components.

Water Inlet and Cooler Systems

At the water inlet connection and within the cooler systems, the O-Ring Seal plays a key role in preventing water leaks. This is vital for maintaining consistent coolant flow, which is necessary for regulating engine temperature.

Engine Oil and Lubricating Systems

In the engine oil and lubricating oil cooler module, the O-Ring Seal is utilized to ensure that oil remains contained within the system. This is important for maintaining proper lubrication of moving parts, reducing wear and tear.

Fuel Pump and Cover Assemblies

The O-Ring Seal is employed in the fuel pump and its cover, as well as the front cylinder block and gear covers. It ensures that fuel and lubricants are sealed effectively, preventing contamination and ensuring system efficiency.

Gasket Kits and Sets

In both lower and upper engine gasket kits, the O-Ring Seal complements traditional gasket materials by providing additional sealing at critical points. This enhances the overall seal integrity of the engine block.

Oil Cooler and Housing

Within the oil cooler and its housing, the O-Ring Seal is crucial for maintaining the seal at connection points. This ensures that the oil cooler operates efficiently, helping to maintain optimal oil temperature.

Plumbing and Connections

Across various plumbing systems—such as those for auxiliary cooling, cabin heater, compressor coolant, and turbocharger—the O-Ring Seal is used at quick disconnect connectors and threaded plugs. This ensures that these systems remain leak-free, maintaining their intended function.

Transfer Connections

At water transfer connections, the O-Ring Seal ensures that water flow is uninterrupted and leak-free. This is essential for consistent cooling performance across the engine.

Conclusion

In summary, the 5259924 O-Ring Seal is a versatile component that enhances the reliability and efficiency of various engine systems by providing essential sealing at connection points. Its use in commercial trucks contributes to improved system efficiency, reduced maintenance needs, and enhanced overall performance and dependability of the truck.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.