This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5265284 O-Ring Seal is a specialized component designed for use in commercial trucks. Its primary function is to provide a reliable seal in various engine and system applications, ensuring the integrity of fluid systems and preventing leaks. This seal is integral to maintaining the performance and efficiency of truck engines and related systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section. It functions by creating a seal when compressed within a groove, effectively blocking the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including automotive, aerospace, and industrial machinery 1.

Purpose of the Cummins 5265284 O-Ring Seal

The Cummins 5265284 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the sealing of critical components within the engine or other systems. It is designed to withstand high pressures and temperatures, providing a dependable barrier against fluid leaks. This seal is often used in fuel systems, hydraulic systems, and other areas where maintaining a secure seal is vital for the system’s performance and longevity 2.

Key Features

The Cummins 5265284 O-Ring Seal is characterized by several key features that enhance its performance and durability. These include:

- Material Composition: Typically made from high-quality nitrile rubber or other durable elastomers, ensuring resistance to oils, fuels, and varying temperatures.

- Dimensions: Precisely engineered to fit specific grooves and applications, ensuring a snug fit and effective sealing.

- Design Characteristics: Features such as smooth surface finish and consistent cross-section enhance its sealing capabilities and longevity.

Benefits

Using the Cummins 5265284 O-Ring Seal offers several advantages:

- Improved Sealing Efficiency: The seal’s design and material composition ensure a tight and reliable seal, reducing the risk of leaks.

- Longevity: High-quality materials and precise engineering contribute to the seal’s durability, extending its service life.

- Resistance to Operating Conditions: The seal is designed to withstand high pressures, temperatures, and exposure to various fluids, making it suitable for demanding commercial truck applications 3.

Installation Considerations

Proper installation of the Cummins 5265284 O-Ring Seal is crucial for ensuring its effectiveness and longevity. Guidelines and best practices include:

- Cleaning the Groove: Ensure the sealing groove is clean and free of debris to prevent damage to the O-Ring during installation.

- Proper Lubrication: Use a compatible lubricant to facilitate installation and reduce the risk of damage.

- Avoiding Twisting: Handle the O-Ring carefully to avoid twisting or damaging it during installation.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, extrusion, and degradation. Steps for diagnosing and resolving these issues include:

- Inspecting for Damage: Check the O-Ring for signs of wear, cuts, or deformation.

- Ensuring Proper Fit: Verify that the O-Ring is correctly seated in the groove and that there are no gaps.

- Replacing Worn Seals: If the O-Ring shows signs of degradation or failure, replace it with a new one to restore sealing integrity 4.

Maintenance Tips

To maintain the Cummins 5265284 O-Ring Seal and ensure its continued performance, consider the following recommendations:

- Regular Inspections: Inspect the seal during routine maintenance checks for signs of wear or damage.

- Cleaning: Keep the sealing area clean to prevent contamination that could affect the seal’s performance.

- Replacement Intervals: Follow manufacturer guidelines for replacement intervals to prevent unexpected failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company’s commitment to excellence and customer satisfaction has made it a trusted name in the automotive and heavy-duty truck sectors.

Cummins O-Ring Seal 5265284 Compatibility with Engine Models

The Cummins O-Ring Seal part number 5265284 is designed to fit a variety of Cummins engine models. This seal is crucial for maintaining the integrity of fluid systems within the engine, ensuring that there are no leaks that could compromise engine performance. Below is a detailed description of the engines with which this O-Ring Seal is compatible.

B Series Engines

- B4.5 CM2350 B104

- B129B

D Series Engines

- D4.0 CM2620 D103B

F Series Engines

- F2.8 CM2620 F135B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

ISF Series Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

- ISF4.5 CM2220 F123

QSF Series Engines

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

R Series Engines

- R2.8 CM2220 R101B

This O-Ring Seal is engineered to provide a reliable seal in various engine environments, ensuring that the engines operate efficiently and safely. It is essential to use the correct O-Ring Seal for each specific engine model to maintain optimal performance and prevent potential failures.

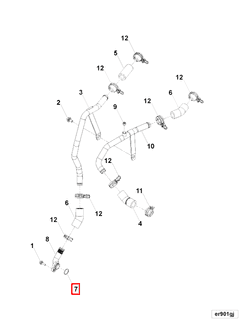

Role of Part 5265284 O-Ring Seal in Engine Systems

The Part 5265284 O-Ring Seal is integral to ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Here’s how it interfaces with the provided components:

Block and Cylinder

In the engine block and cylinder assembly, the O-Ring Seal is used to create a tight seal between mating surfaces, preventing leaks of engine oil and coolant. This ensures that the lubricants and coolants remain within their designated pathways, maintaining optimal engine performance and longevity.

Cooler and Engine Oil Systems

For the engine oil cooler and its associated components like the cooler outlet connection, the O-Ring Seal plays a significant role. It ensures that engine oil flows smoothly through the cooler without any leakage, which is essential for maintaining the oil’s temperature and viscosity, thereby protecting the engine from overheating and wear.

Exhaust Cooler Water Inlet Tube and Flange Assembly

In the exhaust cooler system, particularly at the water inlet tube and flange assembly, the O-Ring Seal is employed to prevent the escape of cooling water. This maintains the efficiency of the exhaust cooling process, which is vital for reducing emissions and enhancing engine performance.

Flanged O-Ring Plug and Fuel Filter Mounting

At the flanged O-Ring plug and fuel filter mounting points, the seal ensures that fuel lines remain pressurized and free from contaminants. This is essential for delivering a consistent fuel supply to the engine, which is critical for combustion efficiency and overall engine reliability.

Lower Engine Gasket Kit and Male Adapter Elbow

Within the lower engine gasket kit and at connections like the male adapter elbow, the O-Ring Seal helps in maintaining the integrity of the gaskets and connections. This prevents any cross-contamination between different fluid systems and ensures that the engine operates within specified parameters.

Plumbing for Auxiliary Cooling, Compressor Coolant, and Exhaust Recirculation Water

In the plumbing systems for auxiliary cooling, compressor coolant, and exhaust recirculation water, the O-Ring Seal is used at various connection points. It ensures that these systems operate efficiently without any fluid loss, which is essential for maintaining the engine’s thermal management and emissions control.

Turbocharger and Reducing Adapter

For the turbocharger and its associated components like the reducing adapter, the O-Ring Seal is crucial in maintaining the seals at high-pressure points. This ensures that the turbocharger operates efficiently, providing the necessary boost without any loss of pressure or fluid.

Tube Connector Elbow and Water Transfer Connections

At the tube connector elbow and various water transfer connections, the O-Ring Seal ensures that coolant flows efficiently through the engine’s cooling system. This is vital for dissipating heat away from critical engine components, thereby preventing overheating and ensuring consistent engine performance.

Conclusion

The Cummins 5265284 O-Ring Seal is a versatile and essential component in maintaining the integrity and efficiency of various engine systems. By providing reliable sealing solutions, this part ensures that engines operate efficiently and safely, preventing leaks and maintaining optimal performance across a range of commercial truck applications.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.