This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5267056 O-Ring Seal, manufactured by Cummins, is a component used in commercial trucks. It is designed to maintain system integrity by preventing leaks and ensuring the proper functioning of various truck systems. Seals play a significant role in the overall performance and reliability of a vehicle, and this Cummins part is no exception.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It is typically made from elastomers, which are materials that can stretch under tension and return to their original shape. Common materials include nitrile rubber, silicone, and fluorocarbon. The O-Ring functions by being compressed between two surfaces, creating a barrier that prevents the passage of fluids or gases 1.

Purpose of the 5267056 O-Ring Seal in Truck Operations

This part is utilized in specific systems within a truck to ensure the integrity of fluid pathways. It is associated with components where fluid dynamics and pressure are critical, such as in the fuel system, hydraulic systems, or engine cooling systems. By maintaining a seal, it helps in the efficient operation of these systems, preventing leaks that could lead to performance issues or system failures 2.

Key Features of the 5267056 O-Ring Seal

The 5267056 O-Ring Seal is characterized by its design and material properties, which include durability and resistance to various chemicals and a wide temperature range. These features make it suitable for the demanding environments found in commercial truck operations. The seal is crafted to withstand the pressures and temperatures encountered in its applications, ensuring long-term performance 3.

Benefits of Using the 5267056 O-Ring Seal

The use of this part offers several advantages. It contributes to improved system efficiency by maintaining seals under pressure, which can lead to better overall performance of the truck. Its longevity and reliability in preventing leaks reduce the need for frequent replacements and repairs, which can be costly and time-consuming.

Installation Considerations

Proper installation of the 5267056 O-Ring Seal is vital for its performance and longevity. Cummins provides guidelines that should be followed to ensure the seal is correctly positioned and compressed. This may include the use of specific tools or procedures to avoid damage to the seal during installation.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failure, can often be traced back to installation errors or environmental factors. Troubleshooting these problems involves a systematic approach to identify the root cause, whether it be improper seating, degradation of the seal material, or exposure to incompatible fluids.

Maintenance and Replacement

Regular maintenance of the 5267056 O-Ring Seal includes inspection for signs of wear or damage. Replacement may be necessary if the seal shows signs of degradation, has been exposed to incompatible substances, or if there is a noticeable decrease in system performance that can be attributed to a faulty seal.

Cummins: A Brief Overview

Cummins is a well-established manufacturer with a broad product range that includes engines, filtration systems, and aftermarket parts. The company has a strong reputation in the commercial truck industry for producing reliable and high-quality components. Their history of innovation and commitment to customer satisfaction has made them a preferred choice for many fleet operators and maintenance professionals.

Cummins O-Ring Seal Part 5267056 Compatibility with Engine Models

The Cummins O-Ring Seal part number 5267056 is designed to fit seamlessly with a variety of engine models. This seal is crucial for ensuring that the engine operates efficiently by preventing leaks and maintaining pressure integrity. Below is a detailed description of how this part fits with the specified engine models:

F2.8 CM2620 F135B, ISF2.8 CM2220 F117, ISF2.8 CM2220 F129

This part is compatible with the F2.8 CM2620 F135B, ISF2.8 CM2220 F117, and ISF2.8 CM2220 F129 engines. This seal is engineered to fit precisely in areas where it is needed to prevent fluid or gas leaks, ensuring that the engine maintains optimal performance. The seal’s material and design are specifically tailored to withstand the operational conditions of these engines, providing a reliable barrier against leaks.

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F108, QSF2.8 CM2880 F114

This part is also compatible with the QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F108, and QSF2.8 CM2880 F114 engines. These engines benefit from the seal’s ability to create a tight, leak-proof connection in critical areas. The seal’s design ensures that it can handle the specific pressures and temperatures encountered in these engines, providing a dependable solution for maintaining engine integrity.

R2.8 CM2220 R101B

This part is compatible with the R2.8 CM2220 R101B engine as well. This seal is engineered to fit the unique requirements of this engine model, ensuring that it can effectively prevent leaks and maintain the necessary pressure levels. The seal’s material and construction are specifically chosen to provide long-lasting performance and reliability in the demanding conditions of this engine.

By ensuring a proper fit and function, the 5267056 O-Ring Seal plays a vital role in the overall performance and longevity of these engine models.

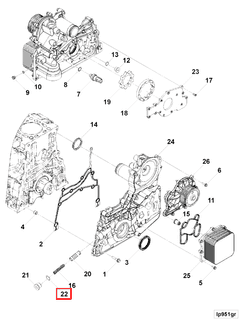

Role of Part 5267056 O-Ring Seal in Engine Systems

The 5267056 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. It is employed in several key areas to ensure optimal performance and prevent leaks.

Oil Management Systems

In the engine oil system, the O-Ring Seal is used to create a tight seal around components such as the oil pump and the lubricating oil cooler module. This ensures that oil is effectively circulated without any leakage, which is essential for maintaining proper lubrication of engine parts.

Cooling Systems

For the oil cooler and lubricating oil cooler, the O-Ring Seal plays a significant role in preventing coolant or oil from escaping. This is particularly important in high-stress environments where temperature regulation is vital for engine longevity.

Structural Seals

In components like the front cylinder block cover and front gear cover, the O-Ring Seal helps in maintaining the structural integrity by sealing gaps that could allow oil or other fluids to seep out. This is important for both the performance and durability of the engine.

Gasket Integration

When integrated with the lower engine gasket kit, the O-Ring Seal enhances the overall sealing capability between mating surfaces. This is crucial for engines that operate under high pressure and temperature conditions.

Specific Component Seals

- Cam Follower Cover: Ensures that the cam follower operates in a sealed environment, reducing the risk of contamination and wear.

- Front Cover: Seals the front cover to prevent oil leakage, which is essential for maintaining the cleanliness and efficiency of the engine compartment.

- Threaded Plug: Used in conjunction with threaded plugs to ensure that any openings in the engine block are properly sealed, preventing fluid loss and contamination.

By effectively sealing these various components, the 5267056 O-Ring Seal contributes to the overall reliability and performance of the engine system.

Conclusion

The 5267056 O-Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its role in preventing leaks and ensuring system integrity is vital for the efficient and reliable performance of various engine systems. Proper installation, maintenance, and understanding of its compatibility with different engine models are essential for maximizing the benefits of this part.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.