This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5271001 O-Ring Seal is a critical component for maintaining the integrity of fluid systems in commercial trucks. It ensures reliable sealing in various applications, contributing to the efficient operation of the vehicle. Understanding its function and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, designed to create a seal between two or more parts. They function by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the Cummins 5271001 O-Ring Seal

The Cummins 5271001 O-Ring Seal is specifically designed for sealing applications within commercial trucks. It is associated with systems where fluid integrity is paramount, such as fuel lines, hydraulic systems, and engine components. By providing a secure seal, it helps maintain system pressure and prevent leaks, which is vital for the proper functioning of these systems 2.

Key Features

This Cummins part is characterized by its material composition, typically made from durable elastomers that offer resistance to a range of operating conditions. Its design specifications ensure a snug fit within the designated grooves, and it may possess unique attributes such as enhanced flexibility or resistance to specific chemicals, which contribute to its performance.

Benefits

The Cummins 5271001 O-Ring Seal offers several benefits, including improved sealing efficiency due to its precise fit and material properties. Its durability ensures long-term performance, even under demanding conditions. Additionally, its resistance to various operating conditions, such as temperature fluctuations and exposure to chemicals, enhances the reliability of the sealing solution it provides 3.

Installation Considerations

When installing the Cummins 5271001 O-Ring Seal, it is important to follow guidelines to ensure proper function. Preparation steps include cleaning the groove and inspecting the O-Ring for any defects. The use of appropriate tools can facilitate installation without damaging the seal. Common pitfalls to avoid include over-lubrication, which can cause the O-Ring to extrude, and improper seating, which can lead to leaks.

Troubleshooting Common Issues

Common problems with O-Ring Seals, such as leaks or failures, can often be traced to installation errors or environmental factors. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, checking the groove for proper dimensions, and assessing the system for any abnormal operating conditions that could affect the seal’s performance.

Maintenance Tips

Regular maintenance of the Cummins 5271001 O-Ring Seal includes periodic inspections for signs of wear or damage. Depending on the operating conditions, replacement intervals may vary. It is important to monitor the seal’s condition and replace it as necessary to prevent system failures and ensure continued efficiency.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product line includes components for engines, filtration, emissions, and fluid power systems, all designed to meet the demanding requirements of commercial applications.

Role of Part 5271001 O-Ring Seal in Engine Systems

The 5271001 O-Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall functionality of the engine.

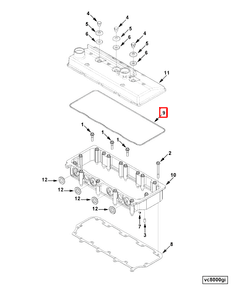

Valve Cover Assembly

In the valve cover assembly, the 5271001 O-Ring Seal is utilized to create a tight and reliable seal between the valve cover and the cylinder head. This seal is important for preventing oil leaks, which can lead to decreased lubrication efficiency and potential engine damage. The O-Ring ensures that the valve cover remains securely in place, maintaining the necessary pressure within the valve train components.

Complete Engine Gasket Kit

When included in a complete engine gasket kit, the 5271001 O-Ring Seal contributes to the overall sealing strategy of the engine. It is often paired with other gaskets and seals to ensure that all potential leak points are addressed. This comprehensive approach helps in maintaining the engine’s performance by ensuring that fluids and gases remain within their designated pathways, thus preventing contamination and ensuring optimal operating conditions.

Arrangement with Other Components

The arrangement of the 5271001 O-Ring Seal with other engine components, such as the valve cover bolts and the cylinder head surface, is designed to enhance the sealing effectiveness. Proper installation of the O-Ring in conjunction with these components ensures that the engine maintains its structural integrity and operational efficiency. This arrangement is particularly important in high-performance engines where precision and reliability are paramount.

Valve Cover

Specifically, within the valve cover, the 5271001 O-Ring Seal works in tandem with the valve cover gasket to provide a dual-layer sealing solution. This setup is effective in withstanding the pressures and temperatures encountered in the valve train area, thus ensuring that the engine operates smoothly without the risk of oil seepage.

Conclusion

In summary, the Cummins 5271001 O-Ring Seal plays a significant role in various engine components, ensuring that seals are maintained across critical junctions. Its proper installation and usage are key to the engine’s longevity and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.