This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5301826 O-Ring Seal is a component designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a role in ensuring the proper functioning of various truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a circular section of elastomer with a round cross-section. It is designed to create a seal between two or more parts in mechanical systems. O-Ring Seals operate by being compressed between flanges on two contacting surfaces and a cylindrical gland in an O-Ring housing. This compression creates a seal that prevents the leakage of fluids or gases and protects against the ingress of contaminants 1.

Purpose of the 5301826 O-Ring Seal in Truck Operation

The 5301826 O-Ring Seal is specifically designed to support the operation of commercial trucks. It is utilized in various application areas within truck systems, including but not limited to, the fuel system, hydraulic systems, and engine components. Its primary role is to ensure a tight seal in these systems, which is vital for maintaining system integrity and efficiency. By preventing leaks and contamination, this part contributes to the overall performance and longevity of the truck’s systems 2.

Key Features of the 5301826 O-Ring Seal

The 5301826 O-Ring Seal is characterized by several design elements that enhance its performance and reliability in truck applications. These features include its material composition, which is chosen for its durability and resistance to various chemicals and temperatures encountered in truck operations. Additionally, the seal’s precise dimensions ensure a snug fit in its designated applications, contributing to its effectiveness in creating and maintaining seals.

Benefits of Using the 5301826 O-Ring Seal

Utilizing the 5301826 O-Ring Seal offers several advantages. These include improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance, reducing the need for frequent replacements. Furthermore, by ensuring a reliable seal, the O-Ring Seal contributes to the overall efficiency and reliability of the truck’s systems, enhancing operational performance 3.

Installation and Maintenance Guidelines

Proper installation of the 5301826 O-Ring Seal is crucial for its effectiveness. This involves ensuring the seal is correctly sized and fitted without damage. Preparation steps may include cleaning the sealing surfaces and inspecting the O-Ring for any defects before installation. Tools required may vary depending on the specific application but generally include basic hand tools for fitting and securing the seal in place. Maintenance tips include regular inspection for signs of wear or damage and replacement as necessary to ensure continued system integrity.

Troubleshooting Common Issues

Common issues with O-Ring Seals in truck applications can include leaks, which may be caused by improper installation, wear and tear, or exposure to incompatible chemicals. Diagnosing these issues involves inspecting the seal and its seating area for damage or misalignment. Resolving these issues may require re-installation of the seal, ensuring proper fit and condition, or in some cases, replacement of the seal to restore system integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to quality and innovation is evident in its extensive range of products, including the 5301826 O-Ring Seal, which is designed to enhance the performance and reliability of commercial trucks.

Cummins O-Ring Seal 5301826 Compatibility

The Cummins O-Ring Seal part number 5301826 is designed to fit a variety of Cummins engines, ensuring a reliable seal in critical areas where fluid or gas leakage could occur. Here is a breakdown of the engines with which this O-Ring Seal is compatible:

B4.5 CM2350 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

These engines are part of the B4.5 CM2350 series, known for their robust performance and reliability. The O-Ring Seal 5301826 is specifically engineered to fit these engines, providing an essential barrier against leaks in various components.

F3.8 CM2350 Series

- F3.8 CM2350 F128C

- QSF3.8 CM2350 F107

The F3.8 CM2350 series engines, including the F3.8 CM2350 F128C and QSF3.8 CM2350 F107, also benefit from the O-Ring Seal 5301826. This part ensures that these engines maintain optimal performance by preventing leaks that could compromise their efficiency and longevity.

F4.5 CM2620 Series

- F4.5 CM2620 F141C

The F4.5 CM2620 F141C engine is another model that is compatible with the O-Ring Seal 5301826. This seal is crucial in maintaining the integrity of the engine’s sealing systems, ensuring that the engine operates smoothly and efficiently.

ISF3.8 CM2220 Series

- ISF3.8 CM2220 F103

Lastly, the ISF3.8 CM2220 F103 engine is also designed to work with the O-Ring Seal 5301826. This compatibility ensures that the engine’s sealing components are well-protected, contributing to the overall reliability and performance of the engine.

By ensuring that the O-Ring Seal 5301826 fits these various Cummins engines, it plays a critical role in maintaining the performance and longevity of the engines.

Role of Part 5301826 O-Ring Seal in Engine Systems

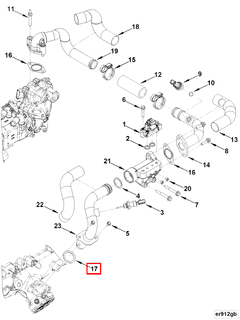

Plumbing Systems

In plumbing systems, the O-Ring Seal (Part 5301826) is instrumental in ensuring the integrity of fluid pathways. It is typically positioned at joints and connections to prevent leaks. The seal’s elasticity allows it to conform to the surfaces it contacts, creating a tight seal that withstands pressure and temperature variations commonly encountered in engine plumbing. This ensures that fluids such as coolant or oil are directed efficiently through the system without loss, maintaining optimal engine performance and longevity.

Exhaust Recirculation Air Systems

Within exhaust recirculation air systems, the O-Ring Seal (Part 5301826) plays a significant role in maintaining the efficiency of the recirculation process. Positioned at various connection points, it ensures that exhaust gases are effectively rerouted back into the combustion chamber. This not only helps in reducing emissions but also enhances fuel efficiency. The seal’s ability to withstand high temperatures and corrosive gases is essential in this application, ensuring that the recirculation system operates smoothly and effectively.

Upper Engine Gasket Kits

In upper engine gasket kits, the O-Ring Seal (Part 5301826) is often used in conjunction with other gaskets to provide a comprehensive sealing solution. It is typically found in areas where traditional gasket materials may not provide sufficient sealing due to irregular surfaces or dynamic movement. The O-Ring’s flexibility and conformability make it ideal for these applications, ensuring that critical engine components such as the valve cover, intake manifold, and other upper engine parts are sealed properly. This prevents oil leaks and maintains the engine’s overall efficiency and reliability.

Conclusion

The Cummins 5301826 O-Ring Seal is a vital component in the maintenance and operation of commercial trucks. Its role in preventing leaks and ensuring system integrity contributes significantly to the efficiency and reliability of truck systems. Proper installation and maintenance of this part are essential for its effectiveness, and its compatibility with various Cummins engines underscores its importance in the commercial vehicle industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.