This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

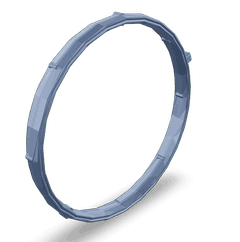

The Diamond Ring Seal, identified by Part #5303284, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This seal is significant in heavy-duty truck applications due to its role in maintaining the integrity of various sealing systems. Cummins, known for its commitment to innovation and quality, produces this seal to meet the demanding requirements of commercial truck operations 1.

Basic Concepts and Functionality

A Diamond Ring Seal is a type of mechanical seal designed to prevent leakage between rotating and stationary parts. It operates by creating a barrier that maintains the separation of fluids or gases within a system. In commercial trucks, these seals are integral to the functionality of various systems, ensuring that fluids remain contained and systems operate efficiently 2.

Purpose of the Diamond Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of a truck by ensuring the effective sealing of rotating equipment. It is commonly applied in systems where fluid dynamics and pressure variations are present, such as in engine components, transmission systems, and hydraulic systems. By providing a reliable seal, it helps maintain system efficiency and prevent fluid leakage, which could lead to operational issues or failures.

Key Features

The primary features of the Diamond Ring Seal include its unique design, which incorporates a diamond-shaped pattern to enhance sealing capabilities. The materials used in its construction are selected for their durability and resistance to wear, ensuring long-term performance under demanding conditions. Additionally, the seal’s design allows for flexibility in accommodating minor misalignments, which can occur in dynamic truck systems.

Benefits of Using a Diamond Ring Seal

Incorporating a Diamond Ring Seal into truck systems offers several advantages. It contributes to improved efficiency by ensuring that fluids are contained within the system, reducing the risk of leaks that could lead to system downtime. The reliability of the seal enhances the overall performance of the truck, while its durability ensures a longer service life, reducing the frequency of replacements and maintenance costs.

Installation Considerations

Proper installation of the Diamond Ring Seal is crucial for its optimal performance and longevity. Guidelines for installation include ensuring the mating surfaces are clean and free from debris, using the correct torque specifications for any fastening components, and verifying that the seal is properly aligned within the system. Following these best practices helps to avoid common installation pitfalls that could compromise the seal’s effectiveness.

Troubleshooting Common Issues

Typical problems associated with Diamond Ring Seals may include leaks, wear, or failure to seal effectively. Potential causes can range from improper installation to operational stresses exceeding the seal’s design limits. Recommended troubleshooting steps involve inspecting the seal and mating surfaces for damage, ensuring correct installation, and assessing system conditions to identify any factors contributing to seal failure.

Maintenance Tips

Routine maintenance practices can prolong the life of the Diamond Ring Seal and ensure continued effective operation. These practices include regular inspections for signs of wear or damage, cleaning the seal and mating surfaces as part of routine system maintenance, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Adhering to these maintenance tips helps maintain the integrity of the sealing system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a pioneer in the automotive and engine manufacturing industry. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and emission solutions. Cummins is committed to innovation, quality, and sustainability, driving advancements in engine technology and efficiency 3.

Compatibility of Diamond Ring Seal Part 5303284 with Cummins Engines

This part is a critical component designed to ensure optimal performance and longevity in various Cummins engine models. It is engineered to fit seamlessly within the engine’s architecture, providing a reliable barrier against leaks and maintaining the integrity of the engine’s internal systems.

Engines with CM2350 Configuration

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

- QSF3.8 CM2350 F107

These engines, featuring the CM2350 configuration, benefit from the Diamond Ring Seal part 5303284. This seal is specifically designed to fit the unique dimensions and requirements of the CM2350 engines, ensuring a perfect seal that prevents oil and other fluids from leaking out, thereby maintaining engine efficiency and reducing maintenance needs.

Engines with CM2620 Configuration

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

The CM2620 engines, including the F3.8 CM2620 F137B and F4.5 CM2620 F139B, also utilize the Diamond Ring Seal part 5303284. This seal is tailored to the specific design of the CM2620 engines, ensuring a robust seal that withstands the high pressures and temperatures typical of these engines. Its precision fit helps in maintaining the engine’s performance and reliability.

Engines with CM2220 Configuration

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF4.5 CM2220 F123

The CM2220 engines, such as the ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, and ISF4.5 CM2220 F123, are also compatible with the Diamond Ring Seal part 5303284. This seal is designed to fit the specific dimensions and requirements of the CM2220 engines, ensuring a tight seal that prevents leaks and maintains the engine’s operational integrity.

Standalone Engines

- F3.8 F102

The F3.8 F102 engine, which does not fall under the CM2350, CM2620, or CM2220 configurations, also utilizes the Diamond Ring Seal part 5303284. This seal is designed to fit the unique specifications of the F3.8 F102 engine, ensuring a reliable seal that helps maintain the engine’s performance and longevity.

By ensuring a precise fit and reliable sealing performance, the Diamond Ring Seal part 5303284 is an essential component for maintaining the efficiency and reliability of these Cummins engines.

Role of Part 5303284 Diamond Ring Seal in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. It is specifically designed to ensure a secure and leak-free connection in several key components.

Connection Points

At connection points within the engine, the Diamond Ring Seal provides a robust barrier against leaks. It ensures that fluids and gases remain contained within their designated pathways, preventing any unwanted mixing or escape. This is particularly important at junctions where different materials or components meet, such as the interface between the engine block and various modules.

Water Inlet System

In the water inlet system, the seal plays a significant role in maintaining the coolant flow. It ensures that the coolant enters the engine without any leaks, which is essential for consistent and efficient cooling. This helps in regulating the engine temperature, thereby enhancing performance and longevity.

Lower Engine Gasket Kit

When integrated into the lower engine gasket kit, the Diamond Ring Seal enhances the overall sealing capability of the gasket set. It provides additional assurance that the lower portion of the engine, which often deals with high pressures and temperatures, remains sealed. This is vital for the prevention of oil leaks and the maintenance of proper lubrication.

Lubricating Oil Cooler Module

In the lubricating oil cooler module, the seal ensures that the oil circulates through the cooler without any loss. This is important for maintaining the oil’s temperature within optimal ranges, which in turn ensures that the engine components are properly lubricated and cooled. Efficient oil circulation directly impacts the engine’s performance and durability.

Oil Cooler

Finally, in the oil cooler, the Diamond Ring Seal helps in maintaining the integrity of the cooling process. By ensuring a tight seal, it prevents any oil from leaking out and coolant from leaking in, which could otherwise compromise the cooling efficiency and lead to engine overheating.

Conclusion

Overall, the Diamond Ring Seal part 5303284 is a key component in ensuring the reliable operation of these engine systems, contributing to the engine’s overall efficiency and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.