5573487

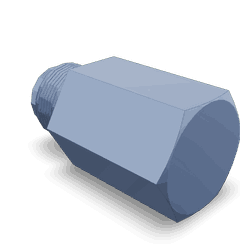

Seal Installer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5573487 Seal Installer is a specialized tool designed to facilitate the proper installation of seals in various components of commercial trucks. Its role is significant in ensuring that seals are correctly positioned and secured, which is vital for the maintenance and efficient operation of these vehicles. By providing a reliable method for seal installation, this tool helps maintain the integrity of the truck’s systems, contributing to overall performance and longevity 1.

Purpose and Functionality

The Cummins 5573487 Seal Installer serves a specific function in the operation of commercial trucks by ensuring that seals are installed correctly. Proper seal installation is crucial for preventing leaks, maintaining system pressure, and ensuring the efficient operation of various truck components. This part aids in achieving precise seal placement, which is necessary for the optimal functioning of parts such as bearings, shafts, and housings 2.

Key Features

The Cummins 5573487 Seal Installer is characterized by several key features that enhance its performance and usability. Its design is engineered to accommodate a range of seal sizes, ensuring versatility across different applications. The materials used in its construction are chosen for their durability and resistance to wear, allowing the tool to withstand the rigors of frequent use in a commercial setting. Additionally, the Seal Installer may include unique attributes such as ergonomic handles for ease of use and precision-machined surfaces to ensure accurate seal placement 3.

Benefits of Using the Seal Installer

Utilizing the Cummins 5573487 Seal Installer offers several advantages. It contributes to improved seal integrity by ensuring that seals are installed correctly the first time, reducing the likelihood of leaks and system failures. This can lead to reduced maintenance costs over time, as well-installed seals require less frequent replacement. Furthermore, the use of this tool can enhance truck performance by maintaining the efficiency of critical systems, thereby contributing to the overall reliability and effectiveness of the vehicle 4.

Installation Process

To use the Cummins 5573487 Seal Installer effectively, follow these steps: First, ensure that the area where the seal will be installed is clean and free of debris. Next, select the appropriate size setting on the Seal Installer to match the seal being used. Carefully position the tool around the seal and press it into place, ensuring even pressure is applied. After installation, verify that the seal is correctly positioned and secure. Always refer to the manufacturer’s instructions for specific guidelines and safety considerations.

Common Applications

The Cummins 5573487 Seal Installer finds typical applications in various aspects of commercial truck maintenance. It is commonly used for installing seals in engine components, such as crankshaft and camshaft bearings, to ensure proper lubrication and prevent oil leaks. In transmission systems, the tool aids in the installation of seals that maintain fluid levels and prevent contamination. Additionally, it is utilized in hydraulic systems to install seals that ensure the integrity of fluid lines and prevent system failures.

Troubleshooting and Maintenance

When encountering issues with seal installations, it is important to first verify that the correct size and type of seal are being used. Ensure that the Seal Installer is properly aligned and that even pressure is applied during installation. Regular maintenance of the Seal Installer, such as cleaning and inspecting for wear, can help prevent issues and ensure its effectiveness. Following these guidelines can contribute to the longevity and reliability of the tool.

Safety Considerations

When using the Cummins 5573487 Seal Installer, it is important to adhere to safety guidelines to prevent accidents and ensure proper usage. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Ensure that the work area is well-ventilated and free of flammable materials. Follow all manufacturer instructions and safety warnings provided with the tool to maintain a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Conclusion

The Cummins 5573487 Seal Installer plays a vital role in the maintenance and operation of commercial trucks by ensuring the proper installation of seals. Its design, characterized by versatility, durability, and precision, contributes to the efficiency and reliability of truck systems. By utilizing this tool, mechanics can enhance seal integrity, reduce maintenance costs, and improve overall vehicle performance. Adherence to safety guidelines and regular maintenance of the Seal Installer are essential for its effective and safe use.

-

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.