This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

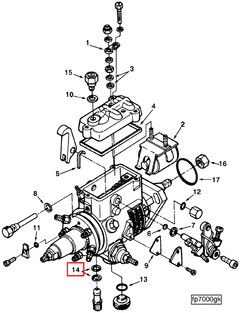

The C0147058000 O-Ring Seal, manufactured by Cummins, is a critical component in the commercial truck industry. Designed for various truck systems, this part ensures reliable performance and efficiency. Cummins’ reputation for high-quality parts and comprehensive product range makes the C0147058000 a trusted choice for truck operators and maintenance professionals 3.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. In mechanical systems, O-Ring Seals prevent the leakage of fluids and gases by filling the gap between mating surfaces. They operate under compression, conforming to the surfaces they seal against, ensuring a tight fit 4.

Purpose of the C0147058000 O-Ring Seal in Truck Operations

The C0147058000 O-Ring Seal is utilized in various applications within truck operations, including fuel systems, hydraulic systems, and engine components. It provides a reliable seal, preventing leaks and ensuring that fluids and gases remain contained within their respective systems, thereby maintaining system integrity and performance 5.

Key Features of the C0147058000 O-Ring Seal

Crafted from high-quality elastomer materials, the C0147058000 O-Ring Seal offers durability and resistance to a wide range of chemicals and environmental conditions. Its design ensures it can withstand significant compression without losing its sealing properties. Additionally, the O-Ring is capable of operating within a broad temperature range, making it suitable for various truck applications 1.

Benefits of Using the C0147058000 O-Ring Seal

Incorporating the C0147058000 O-Ring Seal into truck systems can lead to improved reliability and performance. Its robust construction and material properties contribute to reduced maintenance needs, as it is less likely to fail under normal operating conditions. Furthermore, the seal enhances system efficiency by preventing leaks, which can lead to performance issues or safety concerns 2.

Installation Guidelines

To ensure the optimal performance and longevity of the C0147058000 O-Ring Seal, proper installation is crucial. Begin by cleaning the sealing surfaces to remove any debris or contaminants. Inspect the O-Ring for any damage before installation. Place the O-Ring in the groove, ensuring it is seated correctly without twists or folds. During assembly, avoid excessive force that could damage the O-Ring 3.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks or failures, often due to improper installation, damage, or environmental factors. To troubleshoot, first, inspect the seal and sealing surfaces for any signs of wear, damage, or contamination. Ensure the O-Ring is correctly seated and not overcompressed. Addressing these factors can often resolve sealing issues 4.

Maintenance Tips

Regular maintenance is key to prolonging the life of the C0147058000 O-Ring Seal. Inspect the seal during routine maintenance checks for signs of wear or damage. Replace the O-Ring if it shows signs of degradation or if it has been in service for an extended period. Keeping the sealing surfaces clean and free of contaminants will also contribute to the seal’s longevity 5.

Conclusion

The C0147058000 O-Ring Seal plays a vital role in ensuring the reliability and efficiency of truck systems. Its high-quality construction, durability, and resistance to various environmental conditions make it an essential component for truck operators and maintenance professionals. Proper installation, regular maintenance, and timely replacement are crucial for maximizing the performance and lifespan of this Cummins part.

References

-

R. Matthew Brach. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

General Information. Bulletin Number 3666182. Operation and Maintenance Manual.

↩ -

Sean Bennett, Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ ↩ -

Yushu Wang. Introduction to Engine Valvetrains. SAE International, 2007.

↩ ↩ -

S. A. Miedema, Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.