The C0502076800 Ferrule Seal, manufactured by Cummins, is a critical component designed for use in commercial trucks. It is part of the broader category of sealing solutions that ensure the integrity of fluid systems within these vehicles. Cummins, a well-established name in the commercial truck industry, produces this ferrule seal to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Ferrule Seals

A ferrule seal is a type of mechanical seal that uses a metal sleeve, or ferrule, to create a tight seal between two surfaces. This seal is achieved by compressing the ferrule around a tube or hose, which then forms a secure connection that prevents leaks. Ferrule seals are commonly used in hydraulic, pneumatic, and fuel systems where reliable sealing is crucial. Materials for ferrule seals typically include metals like stainless steel or brass, chosen for their durability, resistance to corrosion, and ability to withstand high pressures 2.

Purpose of the C0502076800 Ferrule Seal

The C0502076800 Ferrule Seal plays a pivotal role in maintaining the integrity of fluid systems within a truck. By providing a secure connection between components, it helps ensure that fluids are transferred efficiently without leakage. This contributes to the overall efficiency and reliability of the truck’s systems, as consistent fluid levels and pressures are maintained.

Key Features

The C0502076800 Ferrule Seal is characterized by its robust design and construction from high-quality materials. These materials are selected for their strength and resistance to the harsh conditions found in commercial truck environments. The seal’s design allows for easy installation and removal, facilitating maintenance procedures. Additionally, its construction ensures a tight seal under various operating conditions, enhancing its performance and durability.

Benefits

Utilizing the C0502076800 Ferrule Seal in truck maintenance and operation offers several advantages. These include improved sealing efficiency, which helps maintain system integrity and performance. The seal’s durability contributes to its longevity, reducing the frequency of replacements. Its resistance to wear and tear ensures reliable operation over time, and its compatibility with other truck components simplifies integration into existing systems.

Troubleshooting and Maintenance

Common issues with ferrule seals may include leaks due to wear, improper installation, or damage. Diagnosing these problems involves inspecting the seal for signs of wear or damage and ensuring it is correctly installed. Regular maintenance practices, such as checking for leaks and ensuring the seal remains in good condition, are important for maintaining optimal performance and longevity of the C0502076800 Ferrule Seal.

Engine Compatibility

3A1.7 Engines

The Ferrule Seal C0502076800 is meticulously crafted to integrate with the 3A1.7 engines. Its precision fit ensures that it effectively seals the connections, preventing any unwanted fluid or air leaks. This is crucial for maintaining the operational efficiency and longevity of the engine.

A2300 Engines

Similarly, the Ferrule Seal C0502076800 is designed to complement the A2300 engines. Its compatibility with these engines is ensured through rigorous testing and design processes, making it an essential part for maintaining the engine’s performance and reliability.

Importance of the Ferrule Seal

The Ferrule Seal C0502076800 plays a pivotal role in the overall functionality of the engines. By providing a secure seal, it helps in maintaining the pressure within the engine systems, which is vital for optimal performance. Additionally, it protects the internal components from external contaminants, thereby extending the engine’s lifespan.

Installation and Maintenance

Proper installation of the Ferrule Seal C0502076800 is crucial to ensure its effectiveness. Technicians should follow the manufacturer’s guidelines to ensure a snug fit and avoid any potential issues. Regular maintenance checks should also be conducted to verify the seal’s condition and replace it if any signs of wear or damage are detected.

Role of the C0502076800 Ferrule Seal in Engine Systems

The C0502076800 Ferrule Seal is an essential component in ensuring the integrity and efficiency of various engine systems, particularly those involving fluid transfer. This seal is instrumental in maintaining a secure connection between different components, thereby preventing leaks and ensuring optimal performance.

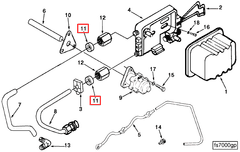

Fuel System Integration

In the fuel system, the C0502076800 Ferrule Seal plays a significant role in connecting the fuel lines to the fuel filter and other critical components. Its primary function is to create a tight seal that prevents fuel leakage, which is vital for maintaining the correct fuel pressure and ensuring a consistent fuel supply to the engine. This seal helps in reducing the risk of fuel contamination and ensures that the fuel system operates efficiently.

Filter Connections

When it comes to filter connections, the C0502076800 Ferrule Seal is used to connect the fuel lines to the fuel filter. This connection is vital for the filter’s effectiveness in removing impurities from the fuel before it reaches the engine. A secure seal ensures that the filter can perform its function without any bypass of unfiltered fuel, which could lead to engine damage over time.

Overall System Reliability

By providing a reliable seal in these connections, the C0502076800 Ferrule Seal contributes to the overall reliability and performance of the engine system. It ensures that all components within the fuel system work together seamlessly, promoting efficient engine operation and longevity.

Conclusion

The C0502076800 Ferrule Seal by Cummins is a vital component for maintaining the integrity and efficiency of fluid systems in commercial trucks. Its robust design, compatibility with various engine types, and ease of installation make it an indispensable part of truck maintenance and operation. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.