This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

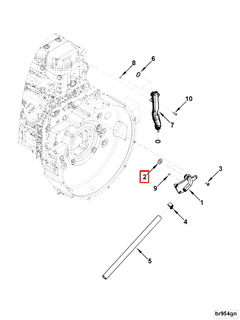

The 2830409 O-Ring Seal, manufactured by Cummins, is a vital component in the commercial truck industry. This seal is designed for various applications within commercial trucks, ensuring the integrity of seals in critical systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in creating reliable seals across a range of applications 4.

Purpose of the 2830409 O-Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks. It is applied in areas where fluid or gas sealing is required to maintain system efficiency and prevent leaks. This seal supports various systems within the truck, contributing to the overall performance and reliability of the vehicle 1.

Key Features of the 2830409 O-Ring Seal

The 2830409 is characterized by its material composition, which is selected for durability and resistance to the operating conditions it will encounter. Its design specifications are tailored to enhance performance and longevity, ensuring it can withstand the demands of commercial truck applications 2.

Benefits of Using the 2830409 O-Ring Seal

Utilizing this Cummins part offers several advantages. It contributes to improved system efficiency by ensuring tight seals, reduces the need for frequent maintenance due to its durable construction, and enhances the reliability of truck operations by preventing leaks and maintaining system integrity 4.

Installation and Maintenance Guidelines

Proper installation of the 2830409 is vital to ensure optimal performance. It should be carefully placed within the designated groove without damage. Regular inspection and replacement according to the manufacturer’s guidelines can help prolong its service life and maintain the effectiveness of the seal 3.

Troubleshooting Common Issues

Typical problems with O-Ring Seals in truck applications may include leaks due to wear, improper installation, or exposure to incompatible fluids. Diagnosing these issues involves inspecting the seal for signs of damage or misalignment and addressing the root cause to resolve the problem effectively 4.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a long history of innovation and commitment to meeting the needs of its customers in the trucking sector 3.

Compatibility with Cummins Engines

This O-Ring Seal is compatible with a range of Cummins engines, providing a reliable barrier against leaks and maintaining system pressure. Below is a detailed overview of the engines with which this seal is compatible:

B6.7 Series

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

ISB Series

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

QSB Series

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

By ensuring that the 2830409 is used in these engines, users can maintain the integrity of their systems and prevent leaks, ultimately contributing to the longevity and reliability of their engines 3.

Role of Part 2830409 O-Ring Seal in Engine Systems

This part is an essential component in various engine systems, ensuring the integrity and efficiency of these systems through its sealing capabilities.

Crankcase Breather System

In the crankcase breather system, the O-Ring Seal is utilized to create a tight seal around the breather passages. This prevents oil vapors and contaminants from entering the engine’s air intake, ensuring clean air is supplied to the combustion chambers. The seal also helps maintain proper crankcase pressure, which is vital for the efficient operation of the engine 4.

Full Engine Gasket Set

When incorporated into a full engine gasket set, the O-Ring Seal plays a significant role in sealing various engine components, such as the oil pan, valve covers, and other critical areas. Its flexibility and durability ensure that oil and other fluids remain contained within their respective systems, preventing leaks that could lead to engine damage 4.

Gasket Kit

In a gasket kit, the O-Ring Seal is often used to seal connections between different engine parts, such as the intake manifold, exhaust manifold, and oil passages. Its ability to conform to irregular surfaces ensures a robust seal, which is essential for maintaining the engine’s performance and longevity 4.

Lower Engine Gasket Kit

Within the lower engine gasket kit, the O-Ring Seal is employed to seal the lower portions of the engine, including the oil pan and front cover. This ensures that oil does not escape, maintaining proper lubrication and preventing contamination of other engine components 4.

Overhaul Kit

In an overhaul kit, the O-Ring Seal is a key component for resealing the engine after a major rebuild. It is used to seal various passages and connections, ensuring that the engine operates efficiently post-overhaul. This includes sealing oil galleries, coolant passages, and other critical areas 4.

Upper Engine Gasket Kit

The upper engine gasket kit utilizes the O-Ring Seal to ensure proper sealing of the upper engine components, such as the cylinder head, intake manifold, and exhaust manifold. This helps maintain the integrity of the combustion process by ensuring that air and fuel mixtures are correctly sealed within the engine 4.

Upper Engine Gasket Set

Similarly, in an upper engine gasket set, the O-Ring Seal is crucial for sealing the upper engine components. It ensures that there are no leaks in the intake and exhaust systems, which is vital for maintaining engine efficiency and performance 4.

Conclusion

Overall, the 2830409 O-Ring Seal is a versatile and reliable component that enhances the functionality and durability of various engine systems. Its compatibility with a range of Cummins engines ensures that it can be effectively utilized in diverse applications, contributing to the overall performance and reliability of commercial trucks.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Cummins Inc. Marine QSB6.7 CM2250, Bulletin Number 4310613, Owners Manual.

↩ ↩ ↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.