This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3000273 O Ring Seal is a component designed for use in commercial trucks. Its primary purpose is to provide a reliable seal in various systems within these vehicles, ensuring the integrity of fluid and gas pathways. This seal is integral to maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 4.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that forms a seal by being compressed within a groove. When pressure is applied, the O Ring deforms to fill the gap between mating surfaces, creating a barrier that prevents the escape of fluids or gases. This mechanism is fundamental in mechanical systems where sealing is required to maintain system pressure and prevent contamination 1.

Role of the 3000273 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is commonly associated with fuel systems, where it helps maintain the pressure and purity of fuel lines. Additionally, it may be used in other systems where sealing is critical to operation, such as hydraulic and pneumatic systems 2.

Key Features of the 3000273 O Ring Seal

The design and material characteristics of the Cummins 3000273 O Ring Seal contribute significantly to its effectiveness and durability. Made from high-quality elastomer materials, it is designed to withstand a wide range of temperatures and pressures. Its precise dimensions ensure a snug fit within the designated grooves, enhancing its sealing capabilities. The material is also resistant to various chemicals and oils, making it suitable for the harsh environments typical of commercial truck applications 3.

Benefits of Using the 3000273 O Ring Seal

Utilizing this Cummins part offers several advantages. Its design ensures improved sealing performance, reducing the risk of leaks and system failures. The durability of the material means it can withstand the rigors of truck operation, providing longevity. Additionally, its resistance to various operating conditions ensures reliable performance across different environments and applications 4.

Installation Considerations

Proper installation of the Cummins 3000273 O Ring Seal is crucial for ensuring optimal performance and longevity. It should be installed in a clean, undamaged groove to prevent damage to the seal during operation. Care should be taken to avoid over-lubrication, as excessive lubricant can lead to seal extrusion. Following manufacturer guidelines for installation will help maintain the integrity of the seal and the system it serves 3.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks, extrusion, and degradation. If a leak is detected, it may indicate a faulty seal that requires replacement. Extrusion can occur if the seal is over-lubricated or if there is a mismatch between the seal and the groove. Degradation may result from exposure to incompatible fluids or extreme temperatures. Regular inspection and maintenance can help identify and address these issues promptly 1.

Maintenance Tips

Regular maintenance of the Cummins 3000273 O Ring Seal is recommended to prolong its service life and maintain system integrity. This includes periodic inspection for signs of wear or damage, ensuring the groove remains clean and undamaged, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Proper maintenance practices will help ensure the continued reliability of the sealing system 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of truck operators worldwide. Its commitment to innovation and quality has made it a trusted name in the industry 2.

Cummins O Ring Seal 3000273 in Engine Applications

The O Ring Seal 3000273, manufactured by Cummins, is a critical component in various engine systems, ensuring the integrity of fluid pathways and preventing leaks. This part is integral to maintaining the operational efficiency and reliability of the engines it is used in.

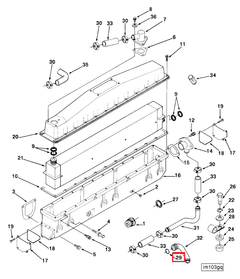

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the O Ring Seal 3000273 is utilized in several key areas to provide a tight seal where different parts meet. Its placement is crucial in maintaining the pressure and preventing fluid loss, which is essential for the engine’s performance and longevity. The seal’s design allows it to withstand the high temperatures and pressures typical in engine environments, ensuring durability and consistent performance over time 3.

The O Ring Seal 3000273’s application in the N14 MECHANICAL engines highlights its versatility and importance in engine design, where precision and reliability are paramount. Its role in sealing critical junctures within the engine underscores its value in the overall engine architecture, contributing to the engine’s efficiency and operational safety 4.

Role of Part 3000273 O Ring Seal in Engine Systems

This Cummins part is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Its application spans across multiple components, each playing a significant role in the overall performance and durability of the engine.

Aftercooler Plumbing

In the aftercooler plumbing system, the O Ring Seal is used to create a tight seal between components, preventing coolant or air leaks. This ensures that the aftercooler operates efficiently, maintaining optimal temperatures for the compressed air, which is essential for engine performance 1.

Aftercooler Water Plumbing

Similarly, in the aftercooler water plumbing, the O Ring Seal is vital for maintaining the seal integrity of connections. This prevents water leaks, ensuring that the cooling process is effective and that the engine operates within the desired temperature range 2.

Air Intercooler

For the air intercooler, the O Ring Seal is employed to seal connections in the plumbing, ensuring that cool air is efficiently transferred to the engine. This helps in reducing the temperature of the air charge, which is beneficial for combustion efficiency and power output 3.

Coolant Heater Starting Aid Plumbing

In the coolant heater starting aid plumbing, the O Ring Seal ensures that there are no leaks in the system. This is particularly important during cold starts, where maintaining the integrity of the coolant flow is essential for efficient engine warm-up 4.

EBM: Plumbing

For the EBM (Engine Block Manifold) plumbing, the O Ring Seal is used to ensure that all connections are leak-free. This is important for maintaining the pressure and flow of fluids within the engine block, contributing to overall engine efficiency 1.

Aft. Water

In the aft water system, the O Ring Seal helps in maintaining the seal at various connection points. This ensures that water flow is consistent and leak-free, which is important for cooling and other engine functions 2.

Heater Outlet Tube

The O Ring Seal is utilized in the heater outlet tube to ensure that there are no leaks in the system. This maintains the efficiency of the heating process, which is crucial for engine operation in cold conditions 3.

Intake Manifold

In the intake manifold, the O Ring Seal is used to ensure that the connections are airtight. This prevents air leaks, which can affect the air-fuel mixture and engine performance 4.

KIM Hotstart Plumbing

For the KIM (Key Ignition Module) hotstart plumbing, the O Ring Seal ensures that all connections are secure and leak-free. This is important for the reliable operation of the hotstart system, especially in cold weather conditions 1.

Lower Engine Gasket Set

In the lower engine gasket set, the O Ring Seal is used to ensure that there are no leaks between engine components. This helps in maintaining the integrity of the lower engine section, which is vital for overall engine performance 2.

Overhaul Gasket Set

During engine overhauls, the O Ring Seal is often included in the gasket set to ensure that all new connections are sealed properly. This is important for the longevity and reliability of the engine post-overhaul 3.

Plumbing KIM Hotstart

In the plumbing for the KIM hotstart system, the O Ring Seal ensures that the connections are secure and leak-free. This is essential for the reliable operation of the hotstart system, particularly in challenging environmental conditions 4.

Rear Water Crossover Tube

For the rear water crossover tube, the O Ring Seal is used to ensure that the connections are leak-free. This maintains the efficiency of the water flow, which is important for engine cooling 1.

Rear Water Plumbing

In the rear water plumbing system, the O Ring Seal ensures that all connections are sealed properly. This prevents water leaks, ensuring that the cooling system operates efficiently 2.

Rear Water Tube

The O Ring Seal is also used in the rear water tube to maintain the integrity of the connections. This ensures that water flow is consistent and leak-free, contributing to effective engine cooling 3.

Upper Engine Gasket Set

In the upper engine gasket set, the O Ring Seal is employed to ensure that there are no leaks between engine components. This helps in maintaining the integrity of the upper engine section, which is essential for overall engine performance 4.

Conclusion

The Cummins 3000273 O Ring Seal is a vital component in the maintenance and operation of commercial trucks and engines. Its design and material properties ensure reliable sealing across a variety of systems, contributing to the efficiency, reliability, and longevity of the vehicles it serves. Proper installation, maintenance, and understanding of its role in different engine systems are crucial for maximizing its benefits and ensuring the optimal performance of the truck or engine.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ ↩ ↩ ↩ ↩ ↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ ↩ ↩ ↩ ↩ ↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF3.8 CM2220 F134B, Bulletin Number 5504164.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.