3007759

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3007759 O Ring Seal is a component used in heavy-duty truck maintenance and operation. It is designed to provide a reliable seal in various applications within the truck’s systems. Understanding its purpose and significance is important for maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that consists of a toroidal shape, which creates a seal when compressed within a groove. It functions by filling the space between two or more mating surfaces, preventing the leakage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3007759 O Ring Seal in Truck Operation

The Cummins 3007759 O Ring Seal plays a specific role in the operation of a truck by ensuring a tight seal in areas where fluid or gas leakage could occur. It is typically placed in grooves within the truck’s systems to prevent leaks and maintain system integrity. Its function is vital for the proper operation of components that rely on sealed environments 2.

Key Features of the 3007759 O Ring Seal

The design and material characteristics of the Cummins 3007759 O Ring Seal make it suitable for its intended applications. It is crafted from materials that offer durability and resistance to various fluids, ensuring it can withstand the operational conditions within a truck. Additionally, it is designed to operate within a specific temperature range, enhancing its reliability in different environments 3.

Benefits of Using the 3007759 O Ring Seal

The Cummins 3007759 O Ring Seal provides several advantages, including improved sealing efficiency and longevity. Its design contributes to the overall reliability of the truck’s systems by ensuring that seals remain intact under pressure and in the presence of fluids or gases. This leads to enhanced performance and reduced maintenance needs.

Installation and Replacement Guidelines

To properly install or replace the Cummins 3007759 O Ring Seal, follow these steps: First, ensure the groove is clean and free of debris. Next, lubricate the O Ring Seal to facilitate installation. Carefully place the seal into the groove, ensuring it is seated correctly. Use the appropriate tools to avoid damaging the seal during installation. When replacing, remove the old seal carefully to prevent damage to the groove.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks or failures, which can be caused by wear, improper installation, or exposure to incompatible fluids. To diagnose these issues, inspect the seal for signs of damage or wear. If a leak is detected, the seal may need to be replaced. Ensure that the groove is clean and free of debris before installing a new seal.

Maintenance Tips

Regular maintenance of the Cummins 3007759 O Ring Seal is important to ensure its longevity and effectiveness. Inspect the seal during routine maintenance checks for signs of wear or damage. Clean the seal and its groove as necessary to prevent contamination. Following these maintenance tips can help extend the life of the seal and maintain system reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company is known for its commitment to sustainability and efficiency in the automotive and heavy-duty truck industry.

Cummins O Ring Seal 3007759 Compatibility

The Cummins O Ring Seal part number 3007759 is designed to fit a variety of Cummins engines, ensuring a secure seal in various applications. Here is a detailed breakdown of its compatibility across different engine models:

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

These engines, part of the KTA19 series, utilize the O Ring Seal 3007759 to maintain proper sealing in critical areas, ensuring optimal performance and longevity.

KTA38 Series Engines

- KTA38GC CM558

The KTA38GC CM558 engine also incorporates the O Ring Seal 3007759, providing essential sealing for its specific operational requirements.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines, including CELECT, GAS, and MECHANICAL variants, all benefit from the O Ring Seal 3007759, ensuring reliable sealing in their respective applications.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, whether CELECT, CELECT PLUS, or MECHANICAL, are compatible with the O Ring Seal 3007759, which is crucial for maintaining the integrity of the engine’s sealing.

N14 Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The N14 series engines, including CELECT, CELECT PLUS, and MECHANICAL versions, all utilize the O Ring Seal 3007759 to ensure proper sealing and operational efficiency.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine incorporates the O Ring Seal 3007759, providing essential sealing for its specific operational needs.

QSM11 Series Engines

- QSM11 CM570

The QSM11 CM570 engine uses the O Ring Seal 3007759 to maintain sealing integrity, ensuring the engine operates efficiently.

QSN14 Series Engines

- QSN14 CM876 N103

- QSNT14 CM876 N102

Both QSN14 CM876 N103 and QSNT14 CM876 N102 engines are compatible with the O Ring Seal 3007759, which is vital for their sealing requirements.

V Series Engines

- V28

- V903

- VTA903 CM2250 V105

The V series engines, including V28, V903, and VTA903 CM2250 V105, all utilize the O Ring Seal 3007759 to ensure proper sealing and operational efficiency.

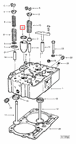

Role of Part 3007759 O Ring Seal in Engine Systems

The O Ring Seal, identified as part 3007759, is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple assemblies and subsystems, providing necessary sealing functions that prevent leaks and maintain system pressures.

Cylinder and Head Assemblies

In the Cylinder Top Level Assembly Head and Cylinder (Top Level Assembly) Head, the O Ring Seal is utilized to ensure a tight seal between mating surfaces. This is particularly important in the Head Cylinder and Cylinder V/VT504 where combustion pressures are high. The seal prevents any gas or fluid leakage, ensuring optimal performance and efficiency of the combustion process.

Performance and Emissions Systems

For EBM: Performance Parts and EBM: Parts, the O Ring Seal is integral in maintaining the performance standards of the engine. In the Emissions Rebuild Kit, it ensures that all emissions control systems operate within specified parameters by preventing any unauthorized release of gases.

Engine Spares and Overhaul Kits

In the Engine Spares Kit and Overhaul Gasket Set, the O Ring Seal is a common component used to replace worn-out seals during maintenance procedures. Its application in the HHp Ovhl Tur/Intl GSK ensures that all gaskets perform their intended function without failure.

Lubrication and Cooling Systems

The Lubricating Oil Cooler Mounting relies on the O Ring Seal to maintain the integrity of the oil cooling system. Similarly, in the Turbocharger Coolant Plumbing and Turbocharger Water Supply Plumbing, it ensures that coolant and water supply systems remain leak-free, thus maintaining efficient engine temperatures.

Injector and Plumbing Systems

In Injector and Injector Plumbing systems, the O Ring Seal is used to ensure that fuel delivery systems remain sealed, preventing any fuel leaks that could lead to inefficient combustion or safety hazards.

Turbocharger and Upper Engine Systems

The Upper Engine Gasket Set often includes O Ring Seals to ensure that all upper engine components, including the Turbocharger, are properly sealed. This is vital for maintaining the turbocharger’s efficiency and the overall performance of the engine.

Specialized Performance Parts

In specialized kits such as the Performance Parts Non AFC, Performance Parts NT-855, and Performance Parts-N-855GS, the O Ring Seal is used to enhance the sealing capabilities of high-performance engines, ensuring they operate at peak efficiency.

VT903 Short Block Kit

In the VT903 Short Block Kit, the O Ring Seal is used to ensure that all internal combustion chamber seals are intact, contributing to the overall reliability and performance of the engine block.

The O Ring Seal, part 3007759, thus plays a multifaceted role in various engine systems, ensuring that each component operates efficiently and reliably.

Conclusion

The Cummins 3007759 O Ring Seal is a critical component in the maintenance and operation of heavy-duty trucks. Its role in preventing leaks and maintaining system integrity across various engine systems underscores its importance in ensuring the efficiency and reliability of these vehicles. Proper installation, regular maintenance, and timely replacement of this part are essential practices for maintaining the performance and longevity of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.