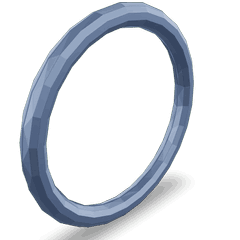

3010157

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3010157 O Ring Seal is a component designed for use in commercial trucks. Its purpose is to provide a reliable seal in various mechanical systems, ensuring the integrity of fluid and gas containment within the truck’s operational systems. This seal is integral to maintaining the efficiency and safety of truck operations by preventing leaks and ensuring proper system function.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a ring with a circular cross-section. It is made from elastomers or rubber-like materials and is used to create a seal between two or more parts. The structure of an O Ring allows it to deform slightly when compressed, creating a tight seal that can withstand pressure and prevent the leakage of fluids or gases. Common materials for O Rings include nitrile rubber, silicone, and fluorocarbon, each offering different levels of resistance to temperature, chemicals, and physical stress 1.

Role of the 3010157 O Ring Seal in Truck Operation

The Cummins 3010157 O Ring Seal plays a specific role in the operation of a truck by ensuring the integrity of seals in various systems or components. It is commonly associated with fuel systems, hydraulic systems, and other areas where fluid or gas containment is necessary. By providing a reliable seal, it helps maintain system pressure, prevent leaks, and ensure the efficient operation of the truck.

Key Features of the 3010157 O Ring Seal

The Cummins 3010157 O Ring Seal is characterized by its design and material properties. It is crafted from high-quality elastomers that offer excellent resistance to the operating conditions found in commercial trucks. The seal’s design ensures a snug fit in its application, enhancing its performance. Unique characteristics may include specific durometer ratings for optimal elasticity and resilience, as well as resistance to oils, fuels, and other chemicals commonly encountered in truck operations.

Benefits of Using the 3010157 O Ring Seal

Utilizing the Cummins 3010157 O Ring Seal offers several benefits. It provides improved sealing efficiency, ensuring that systems operate without leaks. Its durability allows it to withstand the rigors of truck operation, including exposure to high temperatures, pressure fluctuations, and chemical exposure. Additionally, its resistance to various operating conditions contributes to the longevity and reliability of the seal, reducing the need for frequent replacements.

Installation Considerations

Proper installation of the Cummins 3010157 O Ring Seal is vital to ensure its effectiveness. Guidelines recommend cleaning the sealing surfaces to remove any debris or contaminants that could compromise the seal. Using the appropriate tools to install the O Ring without damaging it is also important. Following Cummins’ recommended procedures for installation helps ensure a proper fit and function, contributing to the overall reliability of the seal.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks or failure due to wear, damage, or improper installation. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, checking the sealing surfaces for cleanliness and proper alignment, and ensuring that the O Ring was installed correctly. Addressing these issues promptly can help maintain the integrity of the system and prevent more significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3010157 O Ring Seal includes periodic inspection for signs of wear or damage. Cleaning the seal and its surrounding areas can help prevent contamination that could lead to failure. Replacement should be considered if the seal shows signs of degradation or if leaks are detected. Adhering to recommended inspection intervals and maintenance procedures can extend the life of the seal and ensure continued system reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 3010157 O Ring Seal, designed to meet the demanding requirements of commercial truck operations.

Cummins Engine O Ring Seal 3010157 Compatibility

The O Ring Seal part number 3010157, manufactured by Cummins, is designed to fit seamlessly within various engine models, ensuring optimal sealing performance and reliability. This part is integral to maintaining the integrity of engine systems by preventing leaks and maintaining pressure.

ISB4.5 CM2350 B104 and ISF3.8 CM2220 F103

For the ISB4.5 CM2350 B104 and ISF3.8 CM2220 F103 engines, the O Ring Seal 3010157 is specifically engineered to fit critical sealing points. These engines, known for their robust performance, require high-quality seals to ensure smooth operation and longevity. The seal’s precise dimensions and material composition are tailored to withstand the operational stresses and environmental conditions these engines encounter.

QSK60G and V28

Similarly, the O Ring Seal 3010157 is compatible with the QSK60G and V28 engines. These engines, often used in demanding applications, benefit from the seal’s ability to provide a tight, reliable barrier against leaks. The seal’s design ensures it can handle the high pressures and temperatures typical in these engine environments, contributing to overall engine efficiency and performance.

In all these engines, the O Ring Seal 3010157 plays a role in maintaining system integrity, ensuring that the engines operate at peak efficiency and reliability.

Role of Part 3010157 O Ring Seal in Engine Systems

The Part 3010157 O Ring Seal is a component in various engine systems, ensuring the integrity and efficiency of fluid transfer and system operations. Here’s how it integrates with the provided components:

Base Parts

In base parts, the O Ring Seal ensures that connections remain tight and leak-free, which is vital for maintaining system pressure and preventing fluid loss.

Cooler Lubricating Oil Filter and Cooler Lubricating Oil Mounting Filter

These components rely on the O Ring Seal to create a secure seal between the filter housing and the mounting surface. This prevents oil leaks and ensures that the filtration process is effective.

Engine Rotation and Filter Cooler

During engine rotation, the O Ring Seal helps maintain a consistent seal in the filter cooler, ensuring that lubricating oil is properly filtered without any bypass or leakage, which is important for engine longevity.

Filter, Cooler LO, and Filter-Cooler

In these assemblies, the O Ring Seal is positioned to prevent oil from escaping at connection points, ensuring that the cooling and filtration processes are efficient and that the oil remains clean.

Kit Spares and Lower Engine Gasket Kit

Within spare kits and gasket kits, the O Ring Seal is often included to replace worn or damaged seals, ensuring that when repairs or maintenance are performed, the system remains sealed and functional.

Lube Oil Filter & Co and Lube Oil Filter-Cooler

These components use the O Ring Seal to maintain a secure connection between the filter element and the housing, ensuring that oil is effectively filtered and cooled before re-entering the engine.

Lubricating Oil Cooler Mounting Filter and Lubricating Oil Filter

In these systems, the O Ring Seal ensures that the mounting filter and the lubricating oil filter are securely attached, preventing oil leaks and ensuring efficient oil cooling and filtration.

Lubricating Oil Filter / Cooler and Lubricating Oil Mounting Filter Cooler

These dual-function components depend on the O Ring Seal to maintain a tight seal, ensuring that oil is both filtered and cooled effectively without any loss of pressure or fluid.

Mounting Filter Cooler and Mounting Lubricating Oil Cooler F

For these mounting components, the O Ring Seal is critical in securing the cooler to the engine or frame, preventing leaks and ensuring efficient operation of the cooling system.

Oil Cool Cover and Oil Filter / Cooler

The O Ring Seal in these covers and filters ensures that the oil remains contained within the system, preventing leaks and maintaining the efficiency of the cooling and filtration processes.

Oil Filter Conversion Kit and Oil Gauge Bracket

In conversion kits and gauge brackets, the O Ring Seal is used to ensure that any new fittings or connections are leak-free, maintaining the integrity of the oil system.

Parts, Performance, and Plumbing

Overall, the O Ring Seal plays a role in ensuring that all parts perform as intended, maintaining system performance and preventing issues related to plumbing and fluid dynamics.

Oil Cooler Water, Pump, Lubricating Oil, and Vent Tube

In systems involving oil coolers, pumps, and vent tubes, the O Ring Seal ensures that these components are securely connected, preventing leaks and ensuring that the lubricating oil system operates efficiently.

Conclusion

The Cummins 3010157 O Ring Seal is a critical component in maintaining the efficiency and safety of commercial truck operations. Its role in preventing leaks, ensuring system pressure, and contributing to the longevity of engine systems underscores its importance in truck maintenance and operation. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential to maximizing the benefits of this Cummins part.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.